-

Content Count

76 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by jwhite

-

-

4 years later… build complete.

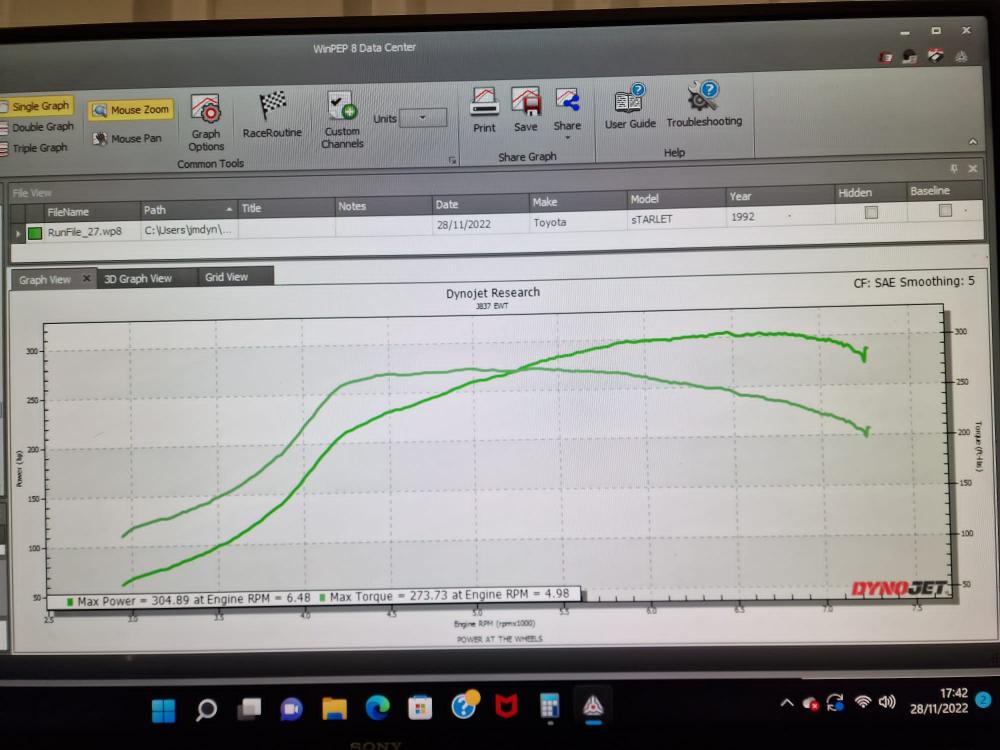

few niggles but she cracked the goal I had in my head since I started which was 300 at the wheels and we finished off with 305whp 274wft-lbs

nice graph also for an old td05 coming onto boost relatively early

anybody who has had any form of input on this build no matter how small I can’t thank you all enough.

-

On 12/9/2021 at 7:20 PM, Gav Missen said:

Where can I find these YouTube vids!

great looking build bud smashing it! Just about to return to my build been over a year since I’ve seen mine!

cheers mate look forward to seeing it!

https://youtube.com/shorts/Snqe8_-9bN0?feature=share

or YouTube ‘Maz Broon’

-

Cheers boys, will do

-

Finally after pretty much 3 years, I finally get to drive this thing again!

still on a basemap tuned to suit gate pressure 0.8/9 bar, 5k safe rev limiter still until I do a few more hundred miles bedding the motor in but it feels so good to be back

advans straight on and time to clock up some miles.

advans straight on and time to clock up some miles.

-

So bit of an update pretty much ironed all the creases out and motor is almost bedded in. Been doing some gentle boosting today and loading up on the dyno to finalise the basemap off and she’s coming onto boost earlier than expected. Can’t wait to go for full power on this thing.

-

-

hi guys getting irregular fuel pressure readings on idle, fitted brand new sytec adjustable fpr and brand new 340lph pump from TD, car has ID 1050cc injectors and is on a haltech ecu. fpr set to 2.3 bar and one minute it reads 3bar next can be reading 1bar. sometimes car wont even start. anybody had anything similar? cheers

-

On 9/10/2021 at 2:59 PM, candy_red said:

I wouldn't know as i installed it with the 1.5mm banjo right away. Did have some smoke issues but was from a slightly kinked return. When i fixed that everything was fine.

But there goes to show you, that even with a 1.5mm feed hole there will easily be flooding in the cartridge. I imagine that it would be much worse with a full size banjo.

Turbos dont need that much oil as we'd like to think. Play it safe and go with 1.5mm.

The spot weld idea sounds good as you would only need to drill the weld and not through the whole damn bolt. Its an easy swap at the end of the day if it doesnt work out and wont cause any harm other than some smoking as its not a ball bearing turbo.

Cheers bud, I’ll get sommet sorted. Thankyou 👍🏼

-

On 9/8/2021 at 9:13 AM, candy_red said:

I remember back when i fitted the TD04 reading somewhere that it needed some kind of restriction and 1.5mm feed hole would be appropriate.

Long story short as i couldnt find a 1.5mm banjo anywhere i got a bolt and drilled a hole along the thread axis and one horizontally essentially creating the banjo i wanted.

Never had a problem with oil consumption and turbo was mint and clean when i removed it after 6 years.

Id imagine a regular banjo with a big opening would certainly flood it and create smoke.

Cheers mate I’ve even been told to just spot weld the banjo bolt sealed, then drill a 1.5mm hole in it as it could have the same effect.

don’t suppose you had any smoke prior to attempting this did you? Did doing this make any noticeable difference ? Cheers

-

Hi guys, sorry if this has been covered before but I’ve got a GReddy TD05 18g,

Recently started my fresh 5e build with this turbo fitted that’s just been rebuilt by midland turbo.

upon startup there is a constant stream of white smoke, led me to believe headgasket but compression test results come back bang on and now the mapper is pointing to the turbo which makes sense as the white smoke does smell strongly of oil.

now I’m getting mixed answers.

some telling me that journal bearing turbos do not need restrictors what so ever,

some may need one,

some come with them fitted as part of the casting,

and I need to run a smaller feed.

has anyone with a greddy td05 encountered a similar issue at all? My feed is rather large and I will check shortly to confirm or not if there is a built in restrictor. Drain is massive and comes out vertically down from the turbo don’t see how this could be an issue.

Any advice at all would be mint. Cheers

-

On 8/25/2021 at 9:47 AM, Sam44 said:

really exited for you. great progress. i bet its such a relief to hear her run. watching with big interest. congratulations.

Thankyou mate it was, teething problems means unfortunately she didn’t run for very long but we will get there

-

BIG UPDATE

SHE RUNS!

Absolutely over the moon, for the past 3 weeks or so I’ve been stuck with not getting a spark, trying various dizzy’s and different dizzy wire layouts I could never get spark, a good crank signal and a good cam signal all at once. Crank signal was good from the start, cam sensor was too intermittent, and I’d only get a spark by spinning the dizzy by hand 🤨.

after countless hours with Rob from racecal on the laptop via teamviewer we never made proper progress. And with changing the dizzy that many times I broke the plug. So it was called at that until it goes for mapping and rob would overlook everything there.

rob messaged me today with a final method and it worked which consisted of changing a few pins on the patch harness to the ecu.

now to start sorting the teething issues with dyno day soon approaching😶.

1: she’s getting very hot very quick. Water temp was circa 82degrees after 5-6 minutes on idle with throttle blips. System bled properly so hoping it’s due to the timing being out still.

2: as mentioned timing is out and it needs sorting ASAP before I start running it up properly.

3: exhaust blow, there is more sound coming from the downpipe area than at the back of the car which is concerning. Will have to Jack it up tomorrow to see as this shouldn’t be happening.

4: my aem wideband is stuck in a reboot cycle which is blagging me, after a quick read it can be due to wiring or potentially damaged in transit. I did buy this as a New but used item so😯. But was still sealed in the box when I got it.

anyway, these are not major and I’ve got no leaks. Overall very happy 😁.

-

On 8/7/2021 at 1:20 PM, Pikey009 said:

Great work mate it’s going to be a monster. Who’s going to map it for you?

It’s going to racecal mate don’t think I’d go elsewhere now.

-

Still here chipping away, cars had lots of wiring done, ecu can now be read on the laptop and the car turns over and builds oil pressure relatively quick🤞🏽. All it needs is tps adjusting and a quick double check then she’ll run.

Managed to hook the hosepipe up to pressure test coolant system, leaked like a sieve at first but managed to stop them. Left to run for 2 hours under quite a substantial amount of pressure and not a drop leaked🤣 ghetto but works.

Also got a pillar pod with a wideband, oil pressure and oil temp.

and another setback was car needed new windscreen as developed a crack out of nowhere which was a pain.

but we’re on the home stretch now. Been almost 3 years since I’ve drove this thing. Mapping is also booked 😅

-

On 6/15/2021 at 12:43 PM, Sam44 said:

leave some power for the rest of us. haha.

boost is in sight.

i cant wait to get on mine now. im flying home on the 23rd.

hopefully next year we can all get together.

Haha cheers bud, ye I want to see how many starlets we can actually get out at once!

-

So buzzing for you josh, and I can vouch for this car she’s a ripper. 300hp in low boost is enough let alone when she hooks at 370! Absolute animal.

-

The old girls home😁

and we’re straight on with wiring, got @wakeabby14helping me (doing most🤣) with the wiring, few more sensors to order what I’ve missed then she’ll be ready to rumble very soon 😎 the end is in sight now boys.

-

On 6/5/2021 at 8:03 AM, Pikey009 said:

Looks fantastic, puts mine to shame!

3 hours ago, Sam44 said:waw fantastic stuff.

Cheers boys.

-

-

-

-

4 hours ago, daniel_g said:

That is coming along now mate, what size of exhaust are you getting made?

3” from turbo back mate. I already have a custom made downpipe and back box just need a mid section to button it up.

-

Been tinkering steady away, wire wheeling a few spots underneath and treating what I’ve missed then a quick brush of hammerite white.

TD 320lph fuel pump fitted to the tank.

Fuel tank plumbed up and back on.

Got my rear axle back on and fitted.

IDworkz rear brake setup fitted.

Whiteline Panhard rod fitted.

IDworkz full poly bush kit fitted.

HEL braided brake lines front and rear.

Fitted a battery up just to crank the motor over to check for oil pressure.

Now the car has gone away for rad and exhaust. Felt strange seeing her on the road. Looks the business now 🤘🏼

-

Toyota starlet MK2 GT Turbo, Forged 5e build

in EP80/EP82 Progress Blogs

Posted

Thanks mate, and yes v power, I honestly weren’t expecting it the car still had teething issues but I saw my arse with the car and thought this is literally make or break 😂 had numerous issues on the dyno and romain wasn’t best pleased but with only some minor tweaks he managed to turn the session around and start pumping some life into her.

He seemed keen for me to sort the last few niggles and come back and get her turned up some more so might see what next year brings😂