Androo26

-

Content Count

66 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by Androo26

-

-

Hi guys .... its been a while but i might just share some recent turbo action regarding the 4cm vs 6cm thing.

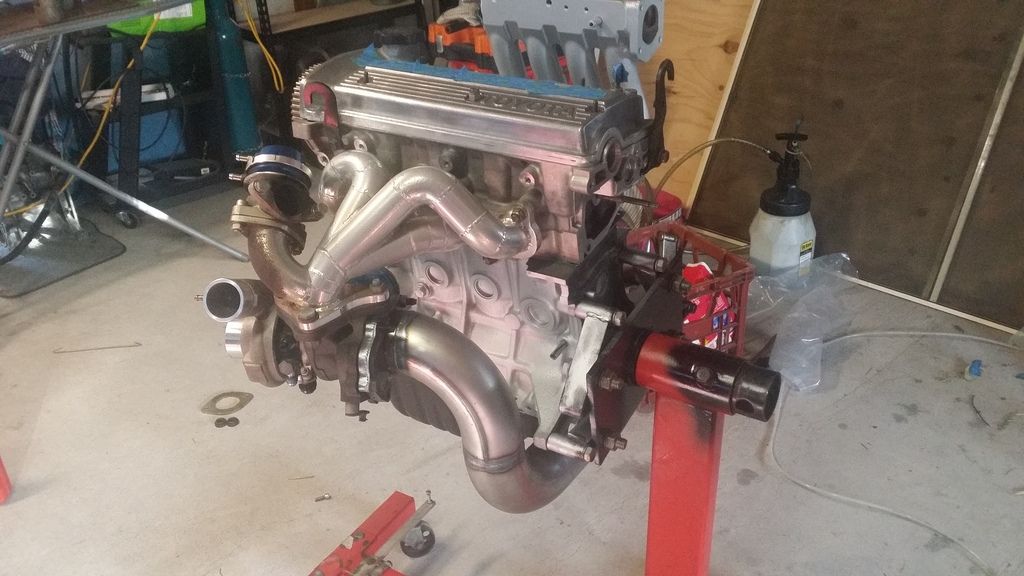

So as you may have already read I had a 4cm TF035 exhaust housing machined out to fit a bone stock TD04L.

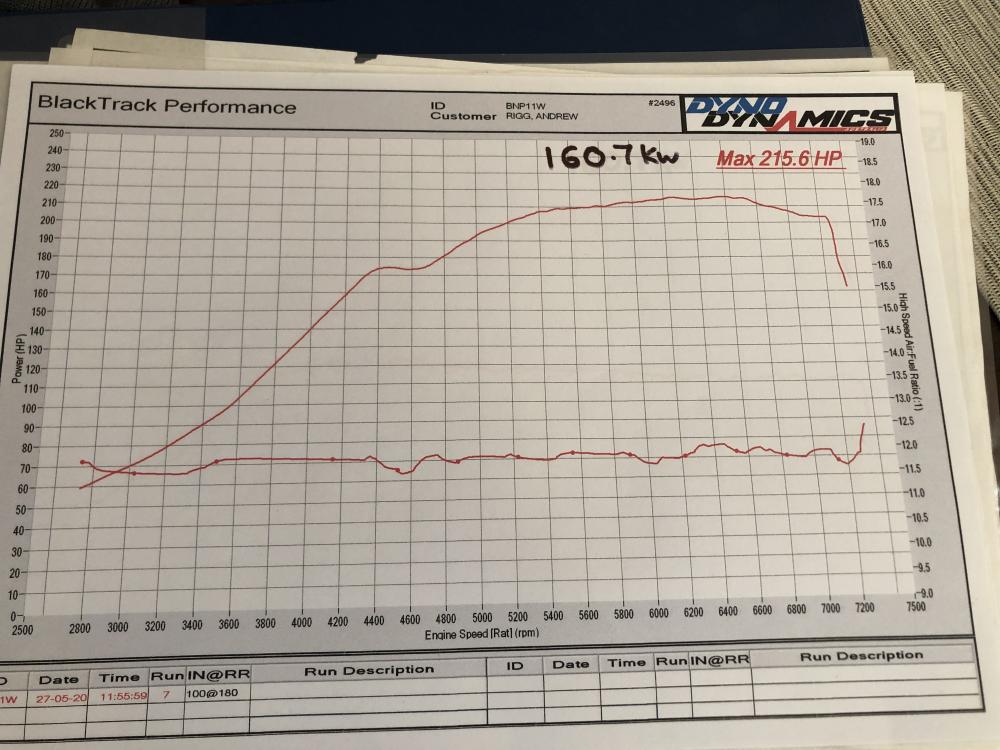

On 19 psi this setup netted me a healthy 160kw at the wheels.

After some time i felt that maybe there was some decent ( not in a good way ) back pressure happening due to the small rear housing.

I built myself a device to measure it and see.

After this I put the exhaust housing back to the stock TD04 6cm one. This netted an 18% reduction in manifold back pressure 😀 Excellent !

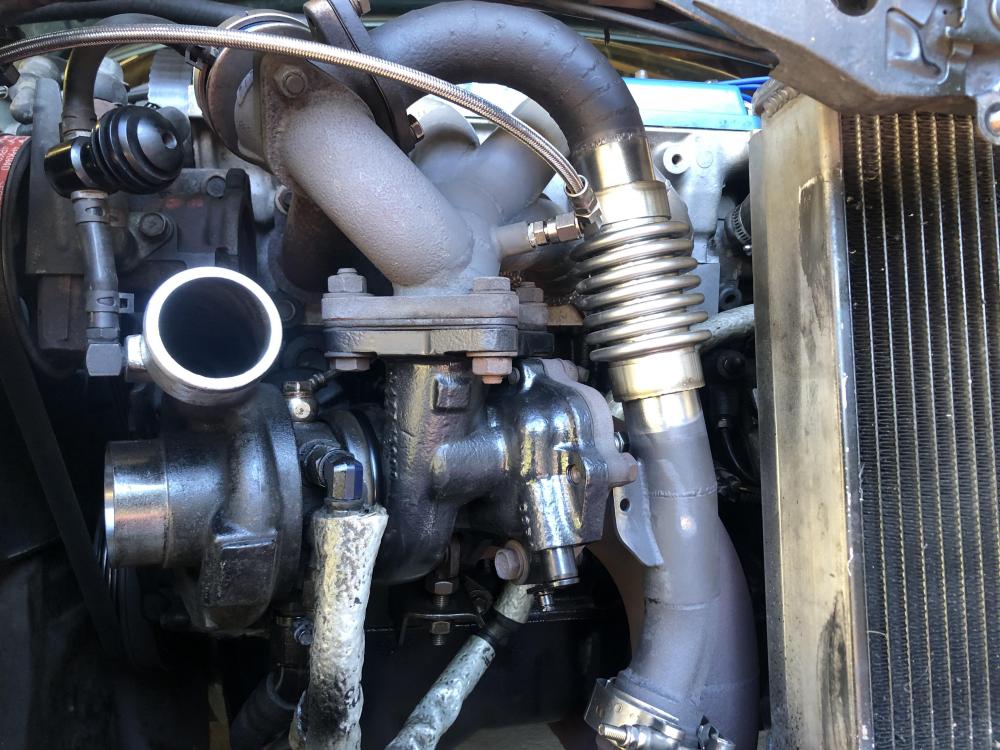

I can go one better , So i got myself a Kinugawa TD04HL-15T With the Billet compressor wheel ect. This turbo is a good size bigger on the turbine wheel side than a TD04L

52mm outer 44mm inner for the HL and 47mm outer and 41.3mm on the inner for the L.

I also opted for the 9 blade turbine wheel . (stock is 12 blades. )

This netted a further reduction in back pressure of 8.5% .

Giving me a exhaust to intake ratio of 1.22:1 at 19psi. Pretty happy with the outcome. It was only 200 rpm later to max psi going from the TD04L to the TD04HL-15T

-

I got mine from a 99 Forester. From my research this may have been the only vehicle to come with the 4cm TF035. The others had 6cm TF035

-

-

As promised ive got out and done some testing on the new setup with great results.

Swapping over to the stock TD04 6cm rear housing has seen a big drop in turbine back pressure over the 4cm unit I had been using.

18.75% reduction in back pressure. From 32psi down to 26psi Making the ratio now 1.33:1 as before it was 1.68:1 (Intake manifold saw 19-19.5psi)

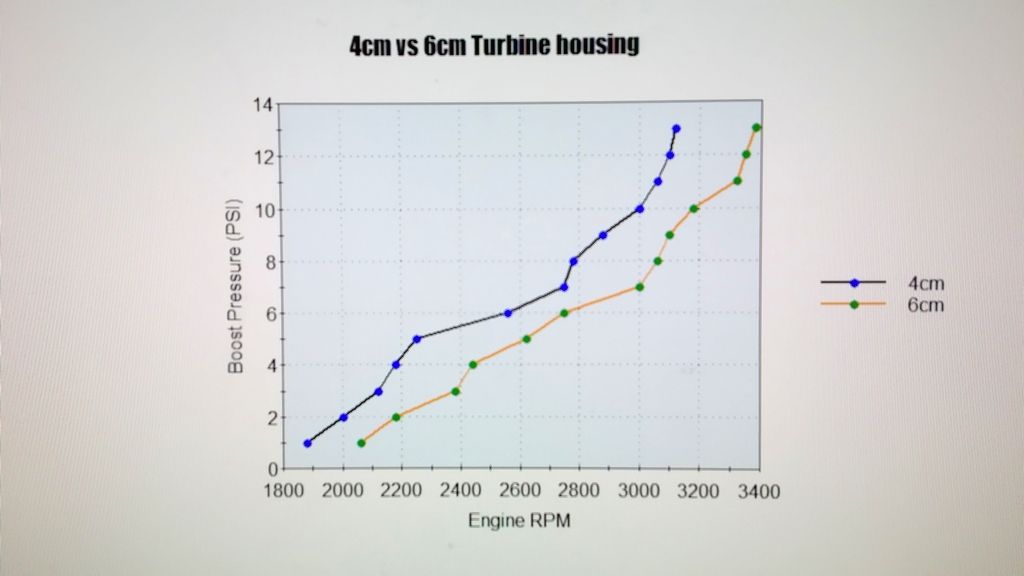

The difference in Boost/ RPM is as follows

4cm housing 5psi at 2700 10psi at 3150 15psi at 3700 6cm.housing 5psi at 2850. 10psi at 3350. 15psi at 3800

As you can see it takes a little more RPM to reach the same boost levels. ( all of 200 rpm for 10 psi at most).

So roughly 100-200 rpm later across the board.

How does it drive ?? It is noticeable to drive between the 2.

The 4 cm is a very fun setup and hits harder invoking wheel spin with ease

The 6cm is more linear and smooth. To be honest i like it better and gets better traction, less shock loading on everything also.

Whats next you say ?? Well Kinugawa make a TD04 that has a 9 blade turbine wheel as opposed to the stock ones having 12. Less back pressure again I

would have thought. Option this with a billet compressor and or step it up to a 15T/19T. Im really not after any more power as it was tuned with the small housing and still made 160kw to the wheels but less back pressure will make for an overall more efficient setup.

Im going to try get this on a dyno again if i can , see what the numbers are.

-

-

How good is that ! I never would have known. Thank you sir.

-

Yeah I think it is unfortunately, I had my entire build on there. Oh well I guess i can just share my stuff here instead.

-

Its been a long time , but ive got some further information to share.

Since the last post Ive built a forged 1.3L 4E and still have the 4cm Turbine TD04L on board. This has made a best of 160.0 Kw at the wheels on 19 psi.

Super fun to drive and traction is a problem even with a Quaife LSD.

Long story short is im getting a bit more serious about lap times and also improving the efficiency of the turbo setup.

So i decided to measure the turbine back pressure vs intake manifold pressure.

Turns out its a bit high for my liking. 1.68:1 . Id much rather it around the 1.5:1 or less.

Im going to get the original 6cm housing Ceramic coated and then swap it over essentially making it a stock TD04L again.

I will re take the turbine back pressure measurement and get back to you guys with the findings.

Still very much enjoying the Starlet life here in Australia.

-

-

I would agree with what the other guys have said too. Read this article and you can make an educated decision for your self by testing it. Not just because others said too. ( hope this helps )

http://www.wallaceracing.com/plug-reading-lm.html

-

I dont have a BOV and mine make the best flutter ever !!

-

I had this on the dyno last week .. Whilst im not going to talk power figures I can tell you that Peak HP was at 5570rpm and peak torque at 4417rpm

At 5600 boost dropped 1 psi so its possible that peak HP may have stayed flat peak till the end.

RPM Range 4E 4cm TF/TD 4E 4cm TD04 5E 4cm TD04

2-3k 16 15 13

3-4k 11 11 10

4-5k 12 10 10

5-6k 15 15 12

Total logs 54 51 45

Here is the log count and as you can see its still pulling well in the upper rpm. 5E for the win thats for sure.

-

Rightio then lads ive done some data logs on spool up with this 4CM TD04 hybrid im running.

For those that dont know my setup its a rebuilt N/A 5EFE completely stock 9.5:1 comp. Turbosmart 38mm External waste gate. 4EFE Intake manifold.

It runs a GFB Atom bleed valve (very basic) so this is about as slow/ linear to build boost as your going to get with no waste gate trickery at all.

The run was performed in 3rd gear, foot flat to the floor from 2000 rpm till redline 6K

1 psi 2000 rpm

3 psi 2120 rpm

4 psi 2250 rpm

5 psi 2380 rpm

6 psi 2410 rpm

8 psi 2560 rpm I might just add that using a bleed valve the gate at this point is almost all the way open as it going to get. So if it were using an EBC you could still have the gate completely closed if you wanted making use of all the exhaust gas

9 psi 2620 rpm making it spool faster again. But Ive chosen the bleed valve because its more gradual and better for traction. (still awesome response on the street)

10 psi 2950 rpm

-

Rightio then lads ive done some data logs on spool up with this 4CM TD04 hybrid im running.

For those that dont know my setup its a rebuilt N/A 5EFE completely stock 9.5:1 comp. Turbosmart 38mm External waste gate. 4EFE Intake manifold.

It runs a GFB Atom bleed valve (very basic) so this is about as slow/ linear to build boost as your going to get with no waste gate trickery at all.

The run was performed in 3rd gear, foot flat to the floor from 2000 rpm till redline 6K

1 psi 2000 rpm

3 psi 2120 rpm

4 psi 2250 rpm

5 psi 2380 rpm

6 psi 2410 rpm

8 psi 2560 rpm I might just add that using a bleed valve the gate at this point is almost all the way open as it going to get. So if it were using an EBC you could still have the gate completely closed if you wanted making use of all the exhaust gas

9 psi 2620 rpm making it spool faster again. But Ive chosen the bleed valve because its more gradual and better for traction. (still awesome response on the street)

10 psi 2950 rpm

-

I read that as though he was comparing a 4cm hybrid TD04 (the same as what im running) vs 04500 (wich is a 14T 4cm TF035) according to the above posts ??

Have I got it wrong here ? Whats the difference between a 13T and 14T Anyone ?

-

Amjad.--- The 04500 is a fair size smaller than the TD04 in both compressor and exhaust wheels so the expected power out put is always going to be less, but without doing back to back dyno runs its hard to say....

At a guess 15-20kw max power difference.

I think the limiting factor with my setup will be the Exhaust housing for sure... but im hoping to get 160KW at the wheel from it on a Built 5E

Its a daily driven to and from work car not a race car.... well sometimes it is lol

-

Righto Colin Ive just been down the shed and got the facts for you.

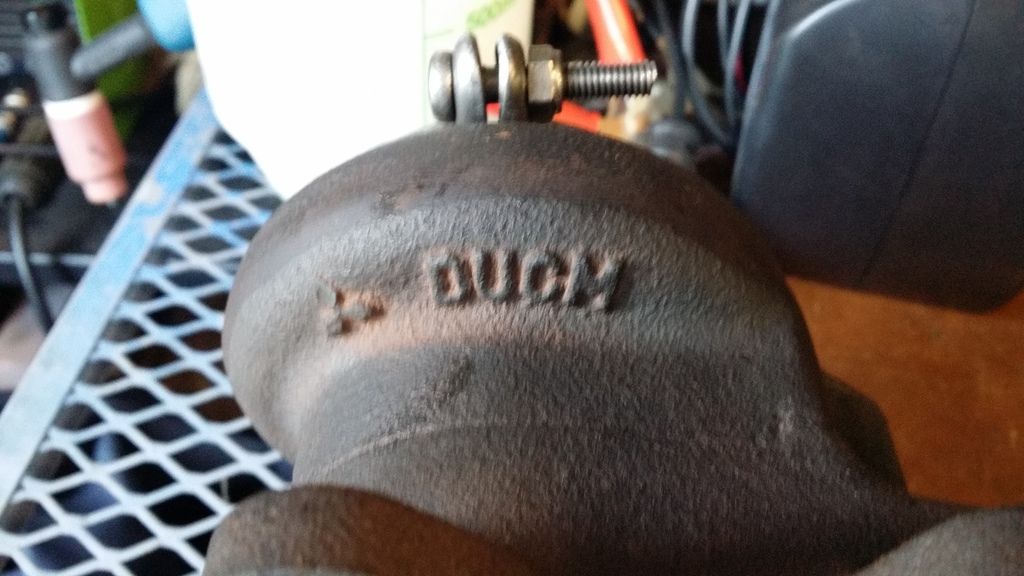

4cm housing does indeed have a 4 cast into it on the inside.

Here are the numbers cast on the side. Confirmed. 35-13900 (4cm)

Also this is cast onto it as well (DUCM)

And im almost certain that this is the compressor cover that came off that one as well.

-

Ive had lots of trouble separating the the core from the housings .... and the best way to do it is apply some heat... works a treat every time.

-

Im sure Ive put this up before . Here is some data I collected after doing back to back testing. Same tune , same boost settings on EBC

This was with the small TF035 Exhaust wheel and TD04 compressor and cover. 4EFE

Here is a link to my TF VS TD write up.

-

Yeah but with the 4cm housing is it not causing high pressure throttling meaning the engine has to work harder just to get the exhaust gasses out?

The 4cm looks way too small.

I might be wrong.. need to see it in person. If mine is 4cm and I dont like the size then we can deffo swap ;)

It looks small but remember that Subaru engineers speced this housing for a 2 litre engine.

All I can say is try it and see for your self.

-

I had this small turbine housing setup on both a hi comp 4E and now the 5E....... Such a good combo for a street car.

The smaller 4cm TF035 cam from 99 model foresters. Thats where mine came from.

Why not just get one of these and put the TDo4 front half on it ?

I have a theory about the tiny TF exhaust wheel.... IT SUX....

The out let to the dump pipe is all of 35mm. If you ask me thats where the restriction is. And on top of that the turbine wheel is taking up area too.

Thats why I went to a TD04 core with the housing machined to suit..... Bolted straight up.

The larger diameter of the TD04 Exhaust wheel makes better use of the exhaust gasses hitting it , it acts just like a longer lever.

Mine made more boost on the same EBC setting than the small wheel. So I had to dial it back.

TF Left VS TD right Exhaust wheels

-

-

Hmmm well I can say this ....

Im now running an internally stock 5EFE 9.5:1 comp with a TD04-13T with a 4cm rear housing machined to suit the td04 exhaust wheel and it is simply awesome. But the only drawback is that

I can only run 10psi using pump 98 gas. Still goes very well though.

Can only imagine how good it would be using E85 and 15 pounds.

I should do some data logs on spool. I know I get full 10 pounds before 3k

-

What are those wheels off originally ?? Looks fat as

Wilwood big brake kit from MRP.

in Braking

Posted

Ive had on my starlet for some time the Big brake kit from MRP in NewZealand.

Great piece of kit bolting straight up with no mods required.

I do track days as often as i can and have just put in a new set of Ferodo DS2500 pads to try out. This part number suits the 275mm rotor and Dynapro Caliper.

Ferodo DS2500 part number is. FPR3149H. Check with your supplier for fitment.