Androo26

-

Content Count

66 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by Androo26

-

-

There is no real reason why it ever needs to be as rich as 10-10.9 unless you are seeing extreme intake temps where extra fuel can assist in cooling the air temps. 11.2 - 12.2 will be rich enough. Just remember that not every cylinder is running at the displayed a/f ratio ...

Its only an average of all four. Some cylinders may be leaner than others. And you dont want it to go pop!!

-

I got a datalogged acceleration run in tonight and here are the results compared to the last turbo setup.

RPM Range 4cm TF/TD 4cm TD04

2-3k 16 15

3-4k 11 114-5k 12 10

5-6k 15 15Total logs 54 51

The lower amount of logs means the faster it went through that rev range. 4cm TD04 wins, Still good at 3-4 but even better at 4-5......

I suspect wind drag comes into it at the 5-6 and it would take a fair bit more power to improve it here . More boost !!!

-

I managed to get a couple of boost logs but as I was about to do a few acceleration logs my laptop battery died.

Any ways here is the info..... exact same test as previous foot to the floor from 2k, gain set at 98 , boost cut at 14.5

RPM BOOST

2000 2 psi

2120 3 psi

2380 4 psi

2560 5 psi

2620 6 psi

2880 8 psi

3210 10 psi at this point the previuos turbo was at 14 psi already

3320 11 psi

3380 14 psi the boost builds so quickly at this point it doesnt even register 12, 13 psi

It takes 260 RPM longer to reach the same boost.

I can tell you that at 3500 its on like donkey kong and seems to have a fair bit more up top..... but im yet to log this... maybe ill get a chance tomorrow.

From what i have read a stock TD04 will arive at this boost some 300 + - rpm later again.

-

4cm TD04 is on and been driven for the first time.........

The first thing me notices, when giving it some shtick was that it hit boost cut almost imediatley wich was set at 14.9psi.

Ok back the duty cycle down a couple of numbers from 65 to 63. 63 with the old turbine wheel would take boost out to 12 psi....

Still boost cut. I finally arrived at a stable 14 psi using 59 as the duty cycle number.

Why did this happen and what does it mean.

Well it makes more boost using the same amount of available exhaust gas...... I like to think of it as the larger turbine wheel is like a larger sail catching more breeze.( bigger suface area )

Also the larger diameter of the turbine wheel acts like a longer lever turning the compressor wheel, making greater use of the exhaust gas and being more efficient at utilising the heat energy.

Less exhaust gas has to pass through the exhaust housing to drive the compressor to 14 psi. Less back pressure .... more power.

I will try to get some data logs on spool up done tonight when its a bit cooler . bout 32 degrees outside now.

-

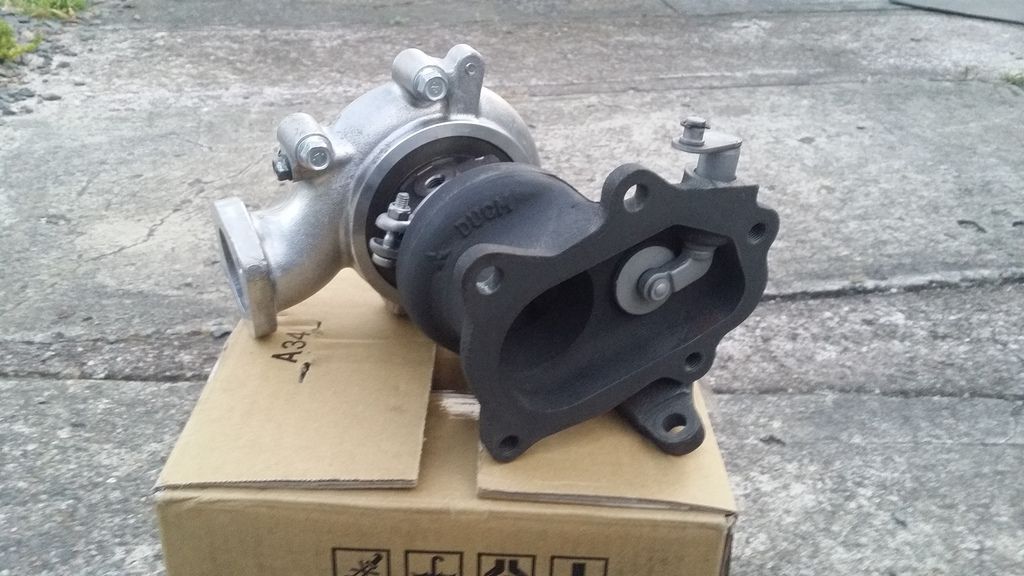

Tommorrow Im removing the 4cm TF/TD hybrid to make way for the 4cm TD04

-

I can highly reccomend the GFB G-Force 2 Boost controller

-

-

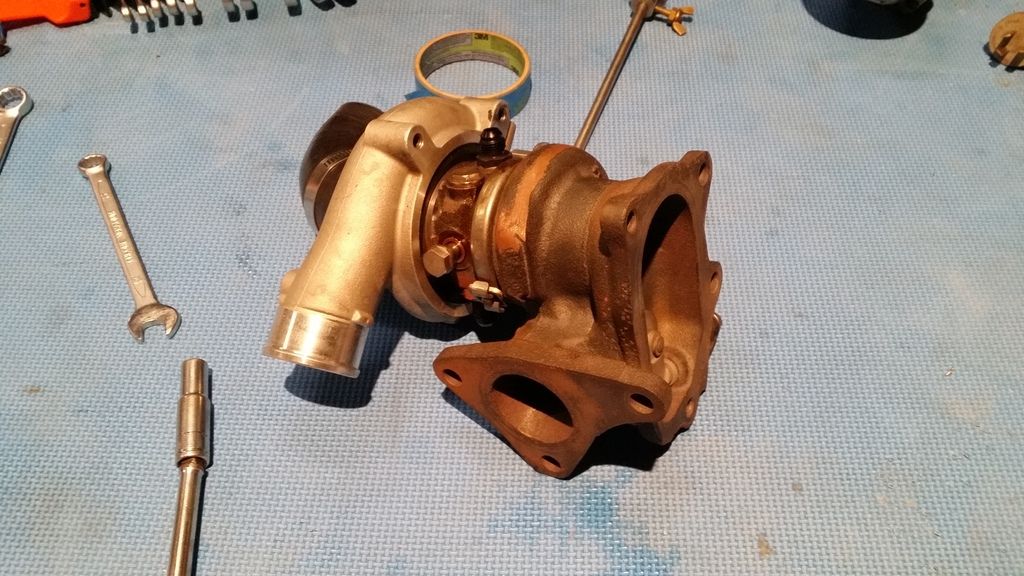

I was supposed to be on the dyno this afternoon testing this 4cm housed TF/TD hybrid ive been running.

But due to circumstances beyond my control I wont be doing it now.

So I will compare data logs instead. I have counted how many times it logged per 1000 rpm Starting at 2K and going to 6K.

It logs at a set times per second, so im really kind of timing how long it takes to get from 2-3 . 3-4 , 4-5 and so on. Acceleration test.

Ok so the 6cm exhaust housing was first and the 4cm one was next.

2-3 3-4 4-5 5-6k ranges

17 13 12 19 logs per one thousand RPM

16 11 12 17

Lets not look into the results too deeply as they arnt exactly scientific ... but the smaller 4cm housing wins in the mid range and going up hills at 110 on the freeway thats for sure. Both setups do pretty well in the 3-5K range. Great for drivability

What will happen when a larger more free flowing TD04 turbine wheel is thrown into the mix. I hope to repeat this test using both 4 and 6cm housings too.

My guess is 200-300rpm later spool up and more power everywhere due to the less back pressure on the motor. -

The answer to that is anyones guess really.... you would just have to try it and see.

The Kinugawa product looked to be made to a high quality standard.... I have yet to hear any bad reports... only good things.

-

I have a Kinugawa TF/TD hybrid (non billet wheel) on mine at the moment. non forged 4efe. Has made 154kw @ 14psi

very happy with it.

In the near future ill be trying a TD04 with the smaller 4cm 99 forrester exhaust housing.

-

Something I noted looking at the Kinugawa Turbo site is the HP rating difference between their TF035 and their TD04 being 33 HP...... with the only difference being the Exhaust wheel sizes.

With 5mm and 6mm being the differences in diameters..... so potentially I could be picking up some horse powers due to better turbine wheel flow...... we will see !!

-

Sorry Collin I missread you question... Ive measured the TF035HM I have here and the compressor wheel measures at 51mm max 39.5mm min diameters.

A TD04l compressor wheel measures at 56 and 40.7mm... So a bit smaller than a 13T

As far as what its called... i dont know. To my knowledge the Forrester TF035 only came in one variation.....as far as the compressor size goes.

-

Just the run of the mill TD04L-13T

Id love to see with this turbo what the max from a 4cm housing is !!

-

-

-

Might just add this here as it gives a quick guide to roll center adjustment and why

The problem I see with the spacers is that you are not actually lowereing the pivot point. See each line is drawn from the pivoting point. All the spacer does is change the angle of the arm.

Look at the small pic aboce the ball joint base is longer therefore the ball joint pivot is placed further.

What the Starlets need is a ball joint that has a longer shaft.

-

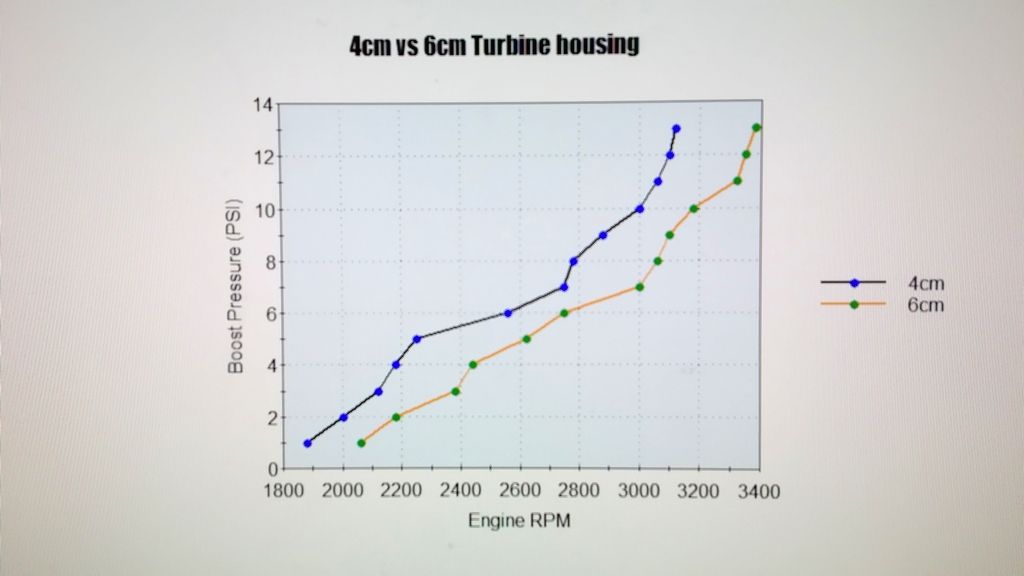

Data logs are in .... and the difinitive answer to "what is the spool difference between th 4cm* and 6cm* turbine housing at 14 psi" is.......

200 rpm.

Here is a graph ive made up compareing the 2.

However this may not seem like much at the peak boost pressure..... but the graph tells the story......on the road its much more punchy around the 3000 rpm mark and quicker to respond to throttle inputs especially when up around the 4K mark (twisty roads ect)

-

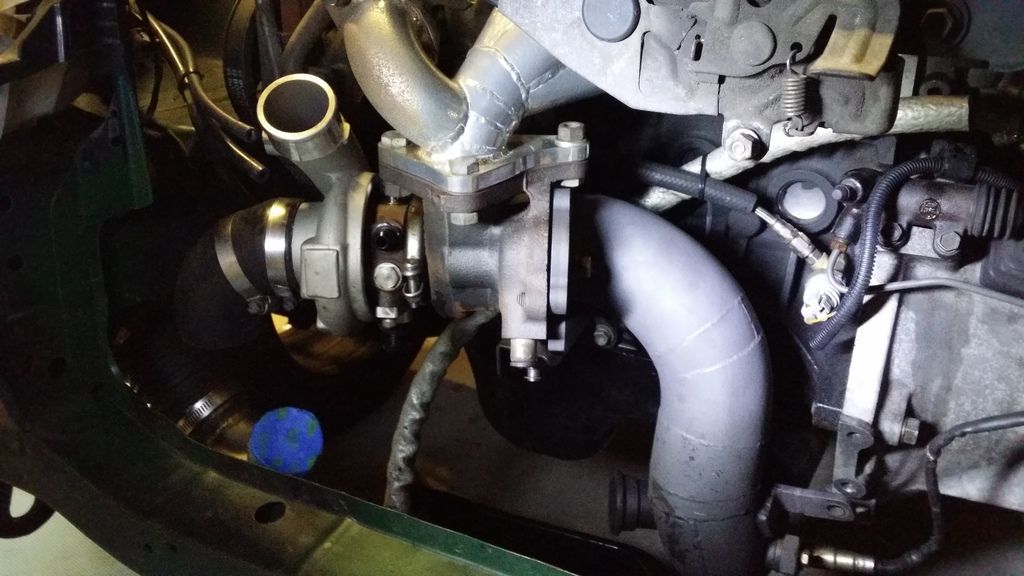

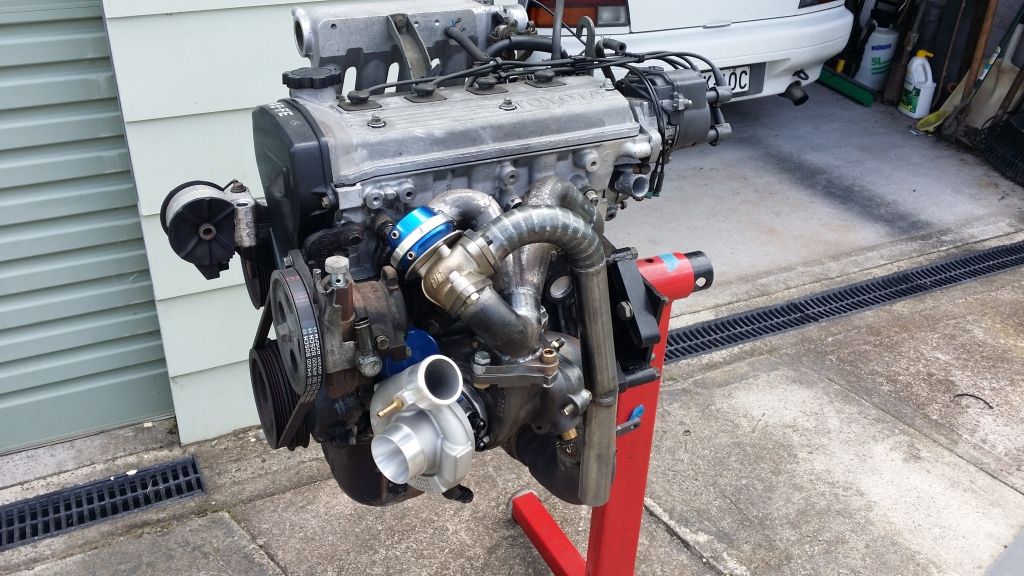

Ive been hard at it over the last couple of afternoons and its now back together except for the front bar and radiator cap. its been started and run upto temperature... Il do the rest in the morning.

An engine bay view from high atop a ladder.

-

Upon further investigation ive run into a few minor alignment issues.

The 4cm housing seems to be 2-3mm shorter from top to bottom, as per the pics.

To combat this ive knocked up a 3mm copper spacer gasket.

Hopefully this will see everything line up again..... I didnt think that it would all be a perfect swap over.

-

-

-

First up appologies for the long time between posts.... but here is somthing to ponder

Tonight I did some data logs to see how quick I could get this curent turbo to spool up by setting the gain control to 95%

This is like pulling the waste gate line off.... only safer beacuse it has a boost cut set at 14.5psi . The gate will stay completly closed untill 95% of the target boost (14psi) is met. 13.3 psi.

Because it ramps so quickly it spikes to 14.5 and cuts boost back to 6 psi straight away...... Its quite amazing how well it does it and can save you from destroying an engine.

So the results were as follows . 5 runs 3rd gear wide open throttle from 2000 rpm. As ive mentioned before the boost controller reads 14 psi and the Microtech sees 13 due to pressure drop.

Out of the 5 runs 3 of them saw 13 psi at 3380rpm and the other 2 saw it at 3320rpm.... so some where in the middle is a good point to start.

No one ever drives there car like this but when normal driving it comes on really hard and fast.... its fun.

After ive swaped to the 4cm housing I will do the same test with the same settings to see the difference in spool up between the 4cm and 6cm Turbine housings.

For those that dont know this engine is / was a naturally aspirated 1.3L 4EFE with a turbo added.

-

-

Turbo goose - the turbo im currently running is basically a 6cm TF035 with TD04 front cover and compressor wheel from a WRX. I plan on swaping to the 4cm exhaust housing and testing the differences.

No modifications to the flanges ... just all stock subaru and kinigawa stuff.

Bussey's Billet GT2867 323bhp V

in EP91 Glanza Progress Blogs

Posted

Im using a TD04 with a smaller than stock exhaust housing machined to suit.

Exhaust housing is a 4cm item from a 99 model Forester TF035

Works very well. After doing back to back data logs I made a graph of it. (4E engine)

4cm housing machined to suit the larger TD04 exhaust wheel.