-

Content Count

53 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by Ep71T

-

-

So after surviving covid 19 I hope this finds you all well !!

We have a Yaris Gr track pack and I had to put the wheels on the starlet to see how bonkers it looks.

So the cheap way out was to sandblast and powder coat my existing Turbina Renault wheels

I am making new rear beam bushings as we speak and the boost is up to 200kpa now

Pink rx400 injectors do the job for now. I am only hitting 90% duty cycle at times.

Pink rx400 injectors do the job for now. I am only hitting 90% duty cycle at times.

-

Could tou send me a pic or the transmission code from the metal tag in the engine compartment ?

Thanks 😀

-

31 minutes ago, Wardyep95 said:

Cheers mate, not sure how easy it would be to awd convert a chassis that wasn't designed for it. Nothing is impossible with enough cutting and welding though.

You are absolutely right mate . But thats where the fun is 😂. We dont have ep85 95 in our market so its hard to get one here.

-

Great car mate. Thanks for those great under car photos of the awd system. I have been looking around for some. I really want to awd my EP71 at this point 😁.

Cant afford a Yaris GR so i will build a lighter version of a Starlet GR 😆

-

Nice one mate.

-

-

Also thinkig that since i have new control arms to just put a 6mm ot larger spacer instead of the anti lift kit for now.

Again any ideas or comments 😀?

-

You could use a carina box or just get a better stock glanza turbo box.. maybe with a factory lsd.

-

Hasnt fallen yet

-

Hey Guys

My current setup is Koni Yellow and Eibach springs.

I modified them by inserting a 2cm spacer inside the strut housing and the tightening the lower mounting bolt to get some more travel from the suspension..

I came across a set another Koni yellow setup but this time its from a corolla ZZE121. I like the fact that the front one have thicker piston and I was wondering If anyone has used strut inserts from another car with success. I will have to modify the strut housing from the ZZE121 in order to fit the EP7 and at the same time maybe I will make a threaded sleeve for some custom spring rates.

Any ideas? 😊

-

-

-

@Claymore

I used an N/A exhaust manifold made a flange for the 12b turbo and outlined it on the manifold. Then I cut the outline (screwed up one manifold lol) and made a tight fit of the flange. Took it at a local welding shop and he welded up the (unweldable cast iron carefully). by the way pick a nice oil free manifold from the wreckers 😆. He did short bursts of welding and let it cool of slowly. I will try to find the pictures and post them. .

@sam44

Thank tou for the kind words 😀

Here is a picture with the virgin (non turbo)grille waiting for some track time.

-

-

As many stated the stock pistons are very capable..

Even on a budget with the right piston ring gap you can get away with crazy boost levels and stock internals. Engine management is key in engine life and how hard you push the internals at lower engine speeds... Stock internals don't like shock torque loads.

Tune right and you will be happy with 200+ bhp all day and be able to put the power on the road.

Forged internals are great when build right ( tolerance wise ) and for the right purpose .

-

Did that work out for you?

-

Do you want noise?

If you do modify the airbox and drop in a K@N or any other panel filter.

If not just drop in a K&N green etc..

-

So its time for an Update.

Fast forward 6 months

I have not lost faith yet !!!

I have not lost faith yet !!!

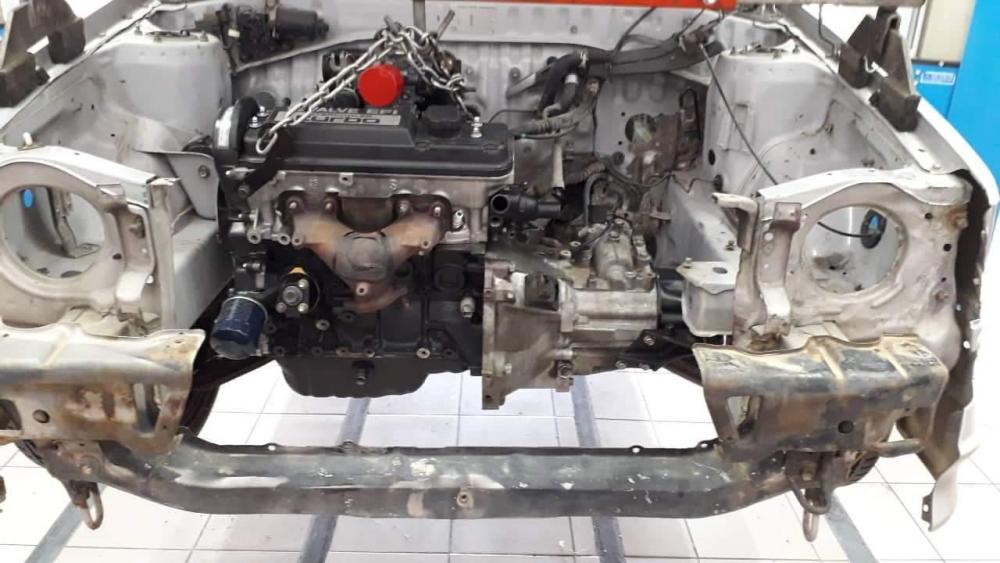

The engine is temporarily fitted to figure out turbo location .

The radiator support was cut and made removable !

The engine bay was cleaned and sprayed where needed .

The radiator was nicely tucked in on the radiator support and as far left as possible.

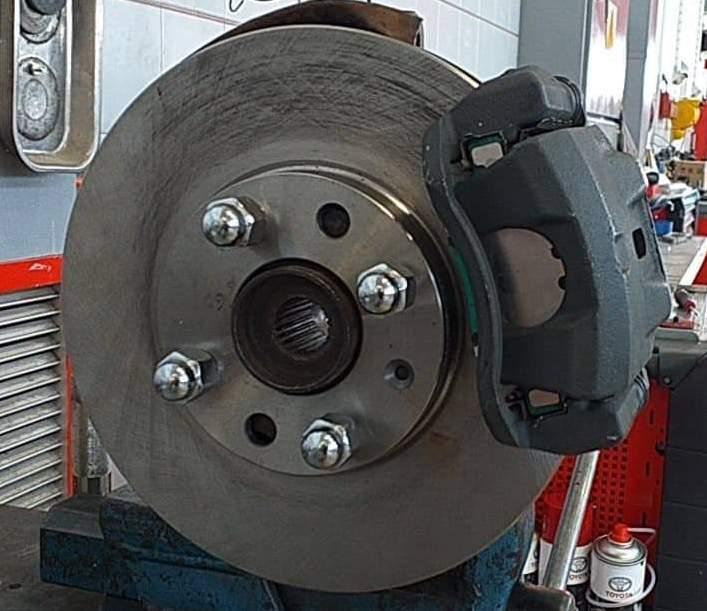

I used the recipe for bigger brakes found on Epic TMC's channel

So In my version I Used the Opel Astra 256 rotors but machined the hub instead of the rotor and got some single pot Celica TS calipers.

Fit is awesome .. will see in the future how they perform.

With white you see the part that hat to go

.

.

-

Great work ! Keep it up

-

So what do you think about stitch welding ? Now the car is stripped down I could stitch it a bit.

Which areas do you recommend? Strut towers? Frame rails ?

-

Anyone knows where to find the valve cover gasket ? It has a stop production from Toyota and no aftermarket luck so far. I made one up for now from a 1zr engine and crazy glue

-

They would turn the oil creamy alright !

They are easy to mix and cheaper to fix than a head gasket .

-

-

Happy new Year All

EP71 turbo restoration project

in EP70 & EP71 Progress Blogs

Posted

Here are the new Bushings for the rear beam,

What a difference... Its one of those things that you must do at day#1

I found a shop that makes any kind of bushing and rubber mount and at any hardness level. It charged me 35 euro per piece.