-

Content Count

229 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by Faiyaz.123

-

-

ive run into the exact same problem splits the belt.

-

14 hours ago, Sam44 said:

I'm very interested in your modification. Do you have a build thread.

Yes I do but haven't updated in a while since I went 5e due to bending a crank.

6 hours ago, Claymore said:If the only problem is the belt being too long 4pk940 means: 4 ribbed belt 940mm in circumference. If you measure the length you need with a piece of string then you can order the correct length belt.

This topic shows its harder.

Is the belt splitting in half on the pulley edge?

Photos of the problem will help.

yes its splitting the belt due it being long I assume .I will take pics tomorrow and post. I've gone from a forged 4e to a forged fully built 5e. At most I've only seen people say make spaces for the brackets on power steering or get a shorter belt but no confirmed pictures etc.

-

as above

Maybe this has been discussed before .I cannot find about anything confirmed and being at a place with no help makes it harder .

I've done a 5efte using 4efte components .now I'm having an issue where the belt is too long .any shorter belt part number? Or a way of making a bracket or anything I can do to get this problem sorted .at the moment current belt is a ram 4pk940 and is splitting it in half.

Please help

-

Maybe in should start by replacing the stock throttle body and cable .

What throttle body can I use as a replacement?

-

As the topic

I'm having trouble with sticky throttle cable.

I'm unsure now if it's the throttle body itself giving up.

Wanted advise i have a zisco intake stock throttle body.

Should I go with another throttle body ? And if so then which one?

I have a haltech elite 1500 which supports drive by wire. So is there anyone who can provide a setup which has been done and tested before ?

Your help would be highly appreciated

-

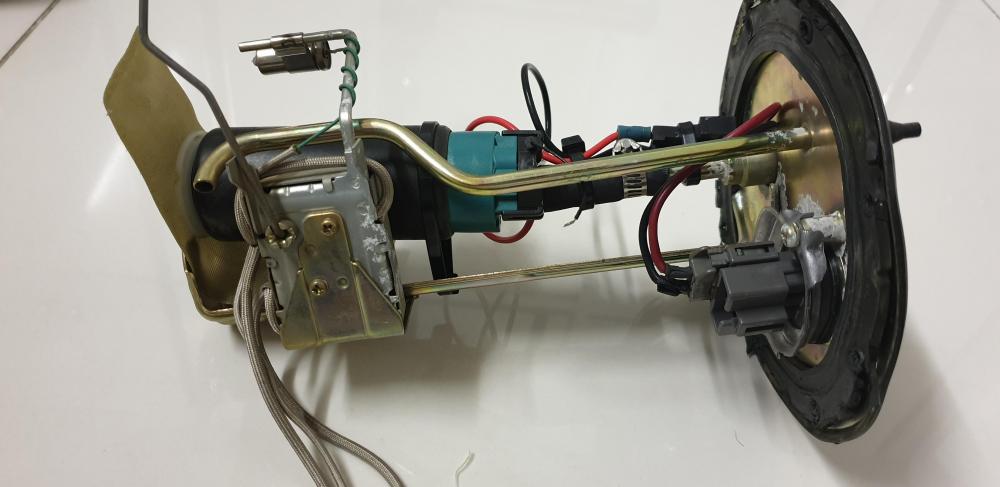

I need some help testing ressistance on my fuel level sending unit .I have tried and I cannot get it right .

Could anyone guide me forward .? I need to values to add into my managment to display the fuel level .I have tried to test the resistance but cant see any reading .either the sender unit is dead and has to be replaced .

Can I replace it with any sending unit? What should I do .? Correct way of testing it ? I have tried every YouTube video lol.

-

I have wiseco pistons 74.5mm in the 4efte .

-

Hello all .

Seems like this year plan on moving onto 5e.

I've just found a complete 5e engine.

I currently have a 4efte forged. I want to know of the forged internals being wiseco pistons with scat rods are usable on the 5e block after engeering or does the 5e block require a different set of forged internals ?

Any help or advice would be helpfull

-

As above still looking for

1.drivers side door handle

2.front calippers and disc stock good condition

-

Any update on this ?

-

As above looking for glanza door handles .

Front standard brake calippers

-

Here's his email address for if anyone can draw they attention and maybe come up with a reasonable offer and publicise it more.

-

On 3/9/2018, 12:13:30, rob_bower said:

Not all the admins who deal with fb are on here all the time or read all the posts.

Rich if there’s still momentum in this let me know.

You will have to contact him through the tegiwa website.

-

-

I've given up with this . This should be gauging interest on ukso Facebook page .but that is up to the admins.

-

Had a familiar problem with my rpm gauge not working .found out I needed some signal converter once you go aftermarket ecu .unsure if that was the case because I changed to a racepak dash. Also has an issue with fuel display on the racepak and had to purchase a signal converter unit from haltech.

Nice clean build , can see alot of hard work in it.

-

On 2/9/2018, 11:38:17, 5e colin said:

Pay attention if the timing cogs arnt touching the studs there close to it

That' exactly what happened .

Seems like the engineer hit a blunder .But managed to get them in .then into another problem .one of the bolts at 40nm just spins round .which means again the engineer has tapped it to big so advised to tap and install a helicoil.

-

Any help?

-

Do post pics and videos when fitted.

Sheesh heavy spending.

Dreams for some of us .

-

On 1/23/2018, 7:27:51, maddox710 said:

Whats wrong with arp head bolts?

On 1/23/2018, 1:50:23, 5e colin said:studs are always better to clamp a headgasket down you get more even clamping force with studs then over bolts ( as they stretch unevenly )

Exactly what happen .the bolts when taken out , had a look and were stretched unevenly .

On 1/23/2018, 2:43:49, maddox710 said:Guarantee 99% of glanza owners will never come anywhere near the lifting point of arp head bolts

I'm sure they are more but if you say 99% then I'm part of that 1%

On 1/23/2018, 3:32:42, daniel_g said:Big Faiyaz up there thought he might!

The car did.

So maybe I need to explain a little more .car was last tuned at 1.5 bar boost with eth mix pushed 414bhp.

When I got the car back it just wasn't feeling right .So we decided to tune through a tuner in Russia with team viewer .and immediately with the tuning progress the car felt much better and as we went up to 1.8 bar. We felt a jerk .upon inspection we realised the headgasket is fine and the head actually started lifting off causing a little water oil mixture . Hence new gasket and studs.

Hope that clears minds .

Now I need more help please lol .

We managed to get the studs in .but realising the longer studs not clearing the cam .we used the old spacers and made the holes a tad bigger for the stud to go through . Will post a pic by tomorrow what I mean. Any idea?

On 1/22/2018, 10:47:23, 5e colin said:Ya there's longer an shorter

You need to drill or grind out the section to pas the nut treu

Pay attention to when cams installed

The OEM bolts is m9 the new m10

When u say pay attention to when cams installed what do you mean ?

-

Ok this looks better.

How deep to I go into the block ?

-

On 1/20/2018, 4:11:15, 5e colin said:

Yes head drilling out can all be don't diy use your pillar drill

Tape up the dec face use gaffa it's strong get yourself a drill and tap guide for m10 get 1 you can bold down to be precise

When head gets installed you will find our where 1 needs grinding a bit to clear stuff

Simple job with correct tools

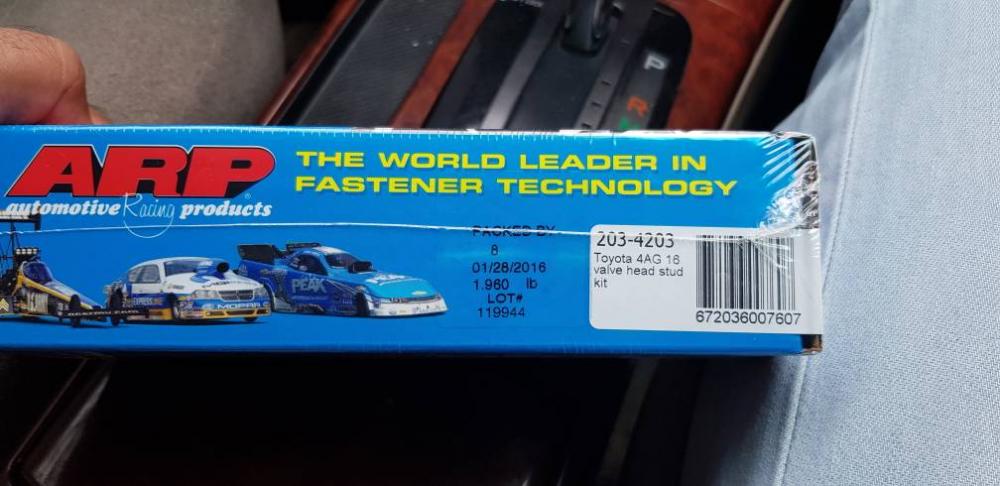

Ok so I'm running Into a few problems have a look at the pics and advise

1st pic is what I purchased

2nd pic as you can see the problem

3rd pic is the old bolt in the middle compared to the studs on the sides. That doesn' look like an Mm difference

Please help

-

The head is off the block at the moment. So that means I have to the head and block ? Any details on measuremets for the head and block.?

-

Hello all , I have tried searcing the correct method but can't seem to find it .

I have taken out the arp headbolts I had .And now want to fit the arp studs.

What needs to be done ? I have got the 4age arp head stud kit .

Thank you

White 97 forged GtX28 ep91 build!

in EP91 Glanza Progress Blogs

Posted · Edited by Faiyaz.123

So maybe it's time a update this .

After my fall down with my previous 4efte engine bending the crank (don't know how)

I've gone 5e will post some pics currently running .I've stopped at 1bar of boost and rev limit at 8krpm .gearbox doesn't seem like to like it but yeah we know there's no alternative to it hence why I lost interest in it.

I've gone side exit its fun even though the person stuck it out the bumper instead of it sitting flush .

Currently trying to figure out out why my p/s belt keeps splitting its a 4efte p/s am I using the wrong length or is there a spacer to be added. Help would be appreciated. I think this is my stopping point before I ended selling or stripping.