-

Content Count

235 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by ChaseWheatley

-

-

-

13 hours ago, Bopthebear said:

Mega build mate credit to you!! Love the brakes and details

💓Thanks bud.... It’s a long way off tho

-

Has anyone asked you want oil viscosity you are running

-

Hmmm I’ll be taking my starlet back to Perth at some point... I have a few mates there with GTs

-

8 hours ago, Patches said:

That's really cool man! Nice build, looking forward to the updates.

Thanks... Yeah it’s slow going that’s for sure...

-

On 3/3/2020 at 7:29 PM, Sam44 said:

Morning.

yeh sorry about that my job is in engine development. I'm used to writing reports. I write a lot at my work station so I have to be fast. Just trying to help.

Ive never done Instagram before I'll have alook.

This is the first design... 4 pistons us the design in there high rpm k24

-

22 hours ago, Sam44 said:

Let us know a price on all them parts if poss. Looking good.

Its crank to rod ratio and piston crown weight that counts on rpm.

The rod can be utilised at this point to work on a slipper piston design and all the benefits A really good piston design could bring to this engine especially.

Reading threw the big Hp builds on here nearly all fail around 300hp, with 250hp seeming to be the point at which they can last. With cylinder temps being the main killer from what I can see.

Im running a better water pump with a closed back impeller. The engine suffers with bad cavitation dropping block pressure around 4krpm upwards slowly getting worse. With cylinder 1 running the hottest threw to 4. The water pump position with the coolant flow speeds just behind cyl 1 being high leads to low pressure points around this area. There's also the power balance issues with the ht lead length difference, the uneven turbo manifold air delivery. Fuel rail devilry problems. A lot of issues to sort before rpm can really be pushed.

But im definitely interested and I recon I could do a great piston design to contribute. A good windage tray and piston oiler jets would also be a big big help. Reducing sump pressures and piston crown temp dramatically. The oiler ports incorporated into the standard rod big end are poor and oil splash/feed issues to the little end will be a problem with increased rpm. A rifle drilled rod the answer supplying the little end with good oil supply. A better oil pump rotor design would also help oil supply. The nissans use a 5 point oil pump rotor were as the Toyota 4e uses a 3 point. The oil filter also has a very small volume of filtered oil. All in all you can see straight away this is a very basic production line motor. To be able to push the 4e in any kinda direction will be an effort. Increasing rpm being 1 of the most challenging.

1 of the areas the engine production line model stands out in is its strength working with in its limits is the best cost affective rout with a lot of off the shelf items available. Areas like topend speed, power levels and engine rpm the fouces points and dream killers.

I've been knee deep in research on the 4e power unit since Christmas and for Toyota/Yamaha to make a 8v head into a16v head very cheaply and it work this well I can only describe as jap magic. This leads to some crazy head flow issues.

message me prices please.

You type so much it’s hard for me to keep up....

just as me on Instagram or something my Instagram is 148carbon and wheatleychase

-

Close up

-

12 hours ago, Sam44 said:

So shorter stroke would suit more. You can go either way.

Im reducing rpm limit to increase the engines service life. On the street car at present.

Im just at the point of testing cam lift on piston clearance and power levels, To work out the rod length required. From what I read there's 3 different cam configuration on the factory e series engine 4efte,4efe,5ehfe. I have them all here.

With me running a mid to large size turbo to amplify the higher rpm power drop off of the lowest factory 4efe cams (lowest lift) that really give great low rpm torque and head gas speeds also aiding turbo spool. I just need dyno graphs to see which way to go with the cams/turbo design.

But yeh the masses will like these light weight strong rods.

Yeah the standard length rods are short already... with a forged crank and Cnc girdle I can run stock bearings clearances or tighter because the parts are stiffer and held in place. Equaling lest rotating assembly flex... and that’s better for bearing life ect.....

I’m building a engine for 11,000rpm not just a street car.. the head work alone is 8k aud

-

9 hours ago, Sam44 said:

Are they standard 4e stroke length/compresstion ratio.

Im looking for some with a longer length to increase compression ratio so I can loose some crown weight and heat.

With the cam setup and valve formation leading to a wedge shape combustion chamber I was going to design a slipper piston to improve gas movement/mixing.

Staying standard stroke/rod or smaller length gives you room to reduce compression ratio and at the same time reshape the piston crown.

cylinder mixing and scaverging on the 4e is poor leading to poor cylinder squish and stall gasses at low rpm. I've seen a lot of head gasket issues to many. Very thick head gaskets also do not help the issue.

To improve/increase compression ratio will improve low rpm engine power output and improve engine efficiency but will lower boost pressure limit on standard pump fuel, (better for road proformance or small tracks)

to lower stroke length gives room for a better piston design no loss of crown thickness or ring land strength and reduces compression ratio for increased boost levels big Hp for track only application really. I've been working with our cad department to design a piston just at present but I have to much crown weight for my target compression ratio. A increase in rod length would would allow me to reduce crown weight and keep my compresstion ratio.

I'm going to run duel fuel, lpg along side of pump fuel together. Really increasing octane and very cost efficient. With lpg the cheapest fuel around.

At work we are getting good torque outputs from running lean fuel mixes with lpg it's very stable and powerful. The new generation of trucks is set to also follow this rout with big mpg saving.

The 5e 1.5ltr engine has the ideal crank to rod ratio for good torque output and stronger crank main caps. The 5e also imploys the longer rod higher compression ratio lower crown weight design, out of factory. Just to give you some advice and research so far.

The figures so far suggest that compression ratio on the 5e could be dramatically improved in a number of areas head material removed and gasket thickness. This will allow rod length to be ruduced yielding Hp. Just what the 5e lacks at no cost to engine cc or 5e torque levels. With rod and piston design maximising power efficiency and reducing the risk of component failure. With piston crown oiler Jets the next natural mod.

I'm playing with the idea of blue printing a very efficient track engine and car for small competion to show case good budget proformance. As well as have some fun in my down time.

My road design is to use the Hp giving 4e and extract as much torque as possible, efficiently from the engine keeping the 4efe standard internals and lower or should I say very smooth boost/power delivery. My aim is 5e Hp to torque output levels.

This also employs the duel fuel aproutch with 40mpg + @250hp the target. Designed for road daily proformance. This is today's performance car design targets.

I hope you realise why I'm telling you this as rod and piston design and production is not cheap. And I'm equally disopointed with the so called unrated products available for these engines.

Well the rods are standard size... I toyed with changing them but I’d I wanted to sell to the masses they would have to be standard and I don’t want a longer stroke I’m building a high rpm engine....

-

On 2/29/2020 at 7:14 PM, Sam44 said:

Now we are talking. What's the estimated cost. Are you pushing rpm.

Whats the desired compression ratio and finally are you designing a piston as well.

And for pistons I’m still deciding on my compression ratio.... but they will be getting made by CP

-

On 2/29/2020 at 7:19 PM, Sam44 said:

Real nice work

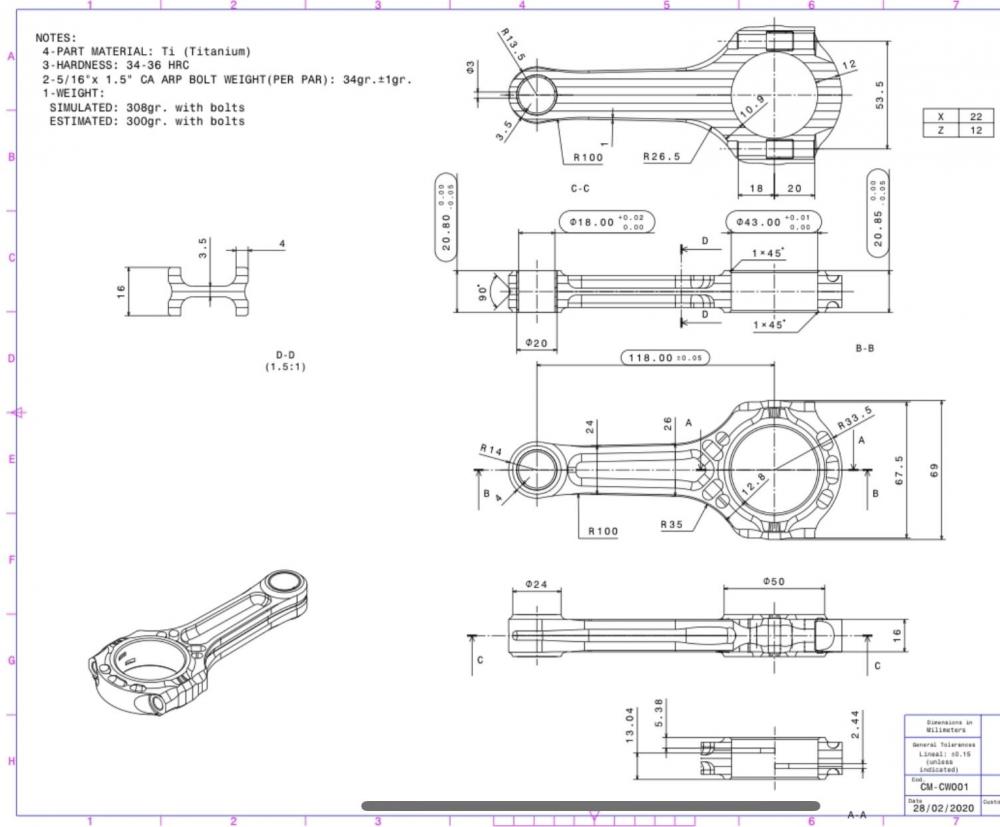

Thanks and thanks to the guys and Saenz for helping me design these

-

On 2/29/2020 at 7:14 PM, Sam44 said:

Now we are talking. What's the estimated cost. Are you pushing rpm.

Whats the desired compression ratio and finally are you designing a piston as well.

Well these cost me a lot but they will be available for anyone on a made to order basis

in 4340, 300m and Titanium

built for 11,000rpm

cost is unknown just yet but depends on what

they are getting made from.... hp rating estimate 500hp+

-

-

-

On 12/10/2019 at 6:51 AM, Gainzy said:

Os Giken is the boss! I added you on fb by the way

Did you what’s your name

-

7 hours ago, akyakapotter said:

Some tasty parts on this bad boy love it.

Cheers nick.

Cheers mate... yeah I’m slowly getting there... just sent my rods to the USA to get custom made ones by SaenZ

-

-

-

43 minutes ago, jiggaman_16 said:

It’s just so u can use the indicator without lifting your hand off the wheel

-

-

Nice Glanza buddy

-

-

11,000rpm GlanzaV Build

in EP91 Glanza Progress Blogs

Posted · Edited by ChaseWheatley

Here you go... Pm me what you think