-

Content Count

1487 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by Sam44

-

-

waw that does look so much better

-

unreal he survived this great reactions from the fire marshals and a testament to the safety in our sport.

so thankful hes ok also thankful hes leaving the sport, dangerous guy in a fast car.

look how titchy the Ferrari is with both seb and charls no wonder there both struggling. how kimmi kept on the power and out of that wall is called SKILL level pro. same place albon hit in FP!!!!!!1

-

hi all alittle knowledge needed.

ive seen people using a 4efte map sensor on the 4efe+t engine and was wondering why?.

i know there are different standalone with there own map sensors and some with out does this help/matter. (can you run the standard 4efe map sensor on the different piggy backs)

i have a 4efe turbo-ed but i didnt do the install myself i got it like this, mine is on the standard map sensor!! on the aem piggy back ecu.

will the ecu master det3 require a 4efte map sensor?.

-

i should be able to make you a bracket ive got afew at home. but when you get your engine i need 1 returning to me as im going to do a e11 build myself. i might end out doing a 16v 7age engine in one.

your welcome if i can help i will.

it will be around march time before i get the e11.

-

ill put some examples up. if you search it there mainly on this site. i wont put them on this build thread.

-

yeh. from what im told tunning developments are the people to see on these. people do rush into building and mapping.

theres just so many builds on here were after mapping the big end fails literally with in a month.

-

great work as always.

-

have you thorough about acl bigend bearings.

there are alot of bigend failures after mapping. literally with in months.

fantastic work by the way. this setup should be so quick.

-

sorry for late reply.

there are 2x options here.

the first option is what i would do and get the car taken to the mappers on a flat bed truck.

the 2nd option is to leave the turbos waste gate fully open. this needs to stay open so try and use a spring to hold/keep this open. this is done so the engine does not build boost pressure. now use a fuel pressure regulator (a good one, sard, fse makes are good units) and set the fuel pressure to 2.1bar this will drop the fuelling on the 4efte injectors close to were it should be and make it derivable.

when you get to the mappers connect the turbos waste gate and up your fuel pressure to 3bar (standard pressure), plus replace your spark plugs at this point with new heat range 7 copper cores (they will be soot fouled. make sure your not running a catalytic converter in the exhaust system at this point, have this installed at a later date. you can also set the fuelling on the map to standard which is explained on the video bellow. (this requires the fuel pressure to be set at standard pressure, but turbo waste gate left open so it does not build boost pressure)

when you drive to the mappers make sure you do not put any load the engine.

the brake servos are different in looks but the same performance.

the engine sensor are explained i previous the how i would do this post above.

Quote -

Yeh no worries. I will help were I can. I just need to put up info regarding the ems control unit/wiring. Then your good to go. Remember get us lots of pictures.

-

Another 5 door. Same as mine.

Nice work as always.

-

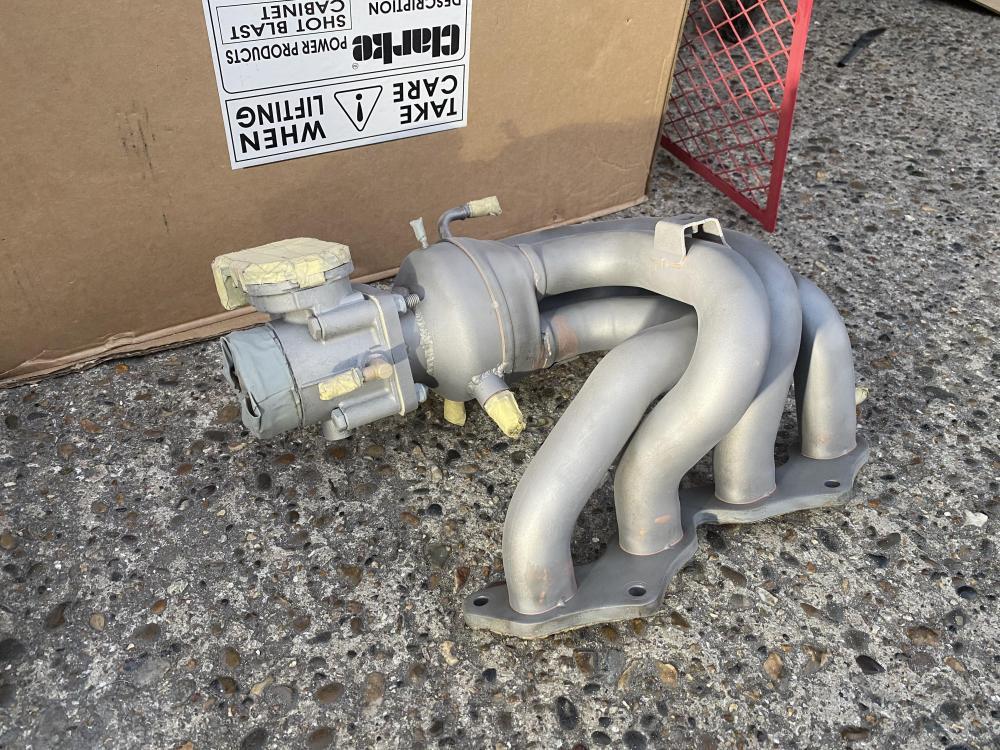

Why we Port grind out (porting) the original exhaust manifold and turbo waste gate.

As I have mentioned in the previous post " in order to hit 190 hp" these modifications are needed.

CLAYMORE build thread recently includes an excellent write up of this process with detailed pictures of where the grinding/porting out should be done. This is to reduce exhaust back pressure and help temps and proformance.

ill put up pictures of a ported out waste gate port on the ct9 turbo I have some here from a hyb turbo. This is done because very quickly after only afew 4efte engine breathing mods (introduction of a fmic and aftermarket air filter+piping) all standard 4efte ct9 engines start to experience boost creep (the point boost pressure starts to rise and the turbos waste gate can not regulate/reduce it). This in turn leads to fuel cut on the 4efte ems.

-

27 minutes ago, Frankieflowers said:

Gotcha. Thanks. What about the manifold? How should it be cut Nd welded to avoid hitting the 4efe gearbox front mount? Do you have pictures?

my mechanic asked me how should he modify the steering wheel oil distributor to get an extra exit for the turbo pipe to the turbo? Is this correct? How ca dot4 oil work with the turbo? Can you please explain. Do you have pictures of that part? Thanks

The only thing I can think of with the brakes would be the servo assistance pipe to the inlet. Just use your original pipe to the original E11 inlet manifold. This will work just fine there will be a inline check valve to stop boost pressure entering the servo diaphram. Dot4 fluid will be good for road use. The rest of the turbo lines come with the 4efte engine.

It's just the decat pipe that might hit the E11 4efe front engine mount as explained above.

-

18 hours ago, wakeabby14 said:

Sound good sam! hit me up your details in PM im going to need an option i dont see this box lasting long>

Cheersas soon as im back in the uk, I will do just that. i think the c64 tops out at around 150mph. are you using your glanza to do quarter mile runs.

-

hello there and welcome to the forum.

-

9 hours ago, Frankieflowers said:

Is the power steering pump bracket you mentioned part of the 4efte engine?

yep it comes with the engine normally.

-

ill carry on editing the how to post above.

-

10 hours ago, Frankieflowers said:

Should I send you another picture for the corner or this is enough? Is the cap cover the plastic boxes on the side?

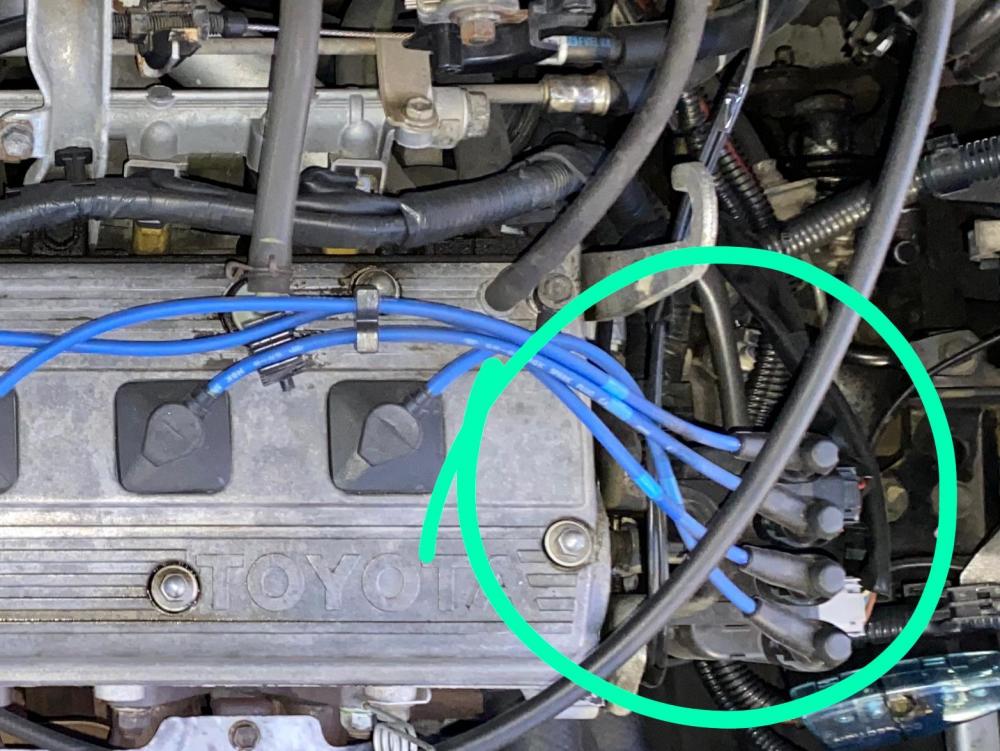

i found this maybe it helps

Starlet Glanza V 1998 4efte

Corolla E11 1998 4efe

yep thanks. it does bolt in place of the distributor and seal the head.

-

10 hours ago, Frankieflowers said:

This is the original 4efte pipe? How will I have to fabricate the modified pipe? Isn’t there any on the market? Any drawing or measures?

rather that it droping straight down it will have to bend back on itself by around 45 deg then drop straight down. this pipe is only a small diameter, some of these are quite a large diameter. with this pipe being quite small you might get away with just cutting away some of the cross member lip/edge.

this is not the 4efte original pipe. the original pipe is a catalytic converter which will defiantly not fit in. this is the aftermarket decat pipe.

-

ill get into this c64/c63 power box next year. we will have to sort something out to get it tested in your 5e high power build, after ive sorted out the install into a ep91.

cangrats josh.

-

my approach for the best & cheapest 4efte swap into a e11 corolla. for good reliable power of around 190hp

parts needed:

complete 4efte engine out of a later glanza 98 model, with all attachments, inlet, exhaust+turbo, flywheel, and much better ct9b turbo. use all the engine mounts and bracket off the e11 4efe fitted to the 4efte (this should be only 1x engine mount on the right side chassis member all the others are attached to the e11 gearbox and will not need touching.

212mm gt turbo/glanza/toyota (original clutch unit will take around 200hp).

new 4efe e11 oil pump and seals, including the crank front main oil seal fitted to the 4efte engine before install with new cam belt if required.

crank rear main oil seal. (serviceable item, they go hard after a certain period of time)

acl standard size big end bearing kit. (tuning developments sell these high load bearing that are a must for today's fast dyno ecu mappers )

4efte decat pipe section of the exhaust.

full aftermarket exhaust system.

aftermarket fuel pump (walbro).

aftermarket piggyback ecu. like the ecu master det3 or aem unit. some of these piggy backs are designed for N/A or turbo use, so make sure you get the correct 1, also some of these have an additional pwm control table (built in boost control) all you need is a pwm valve wired into the control unit.

universal intercooler piping kit, intercooler core to fit the e11.

hks ct9 adjustable turbo actuator.

air filter and piping.

parts i would get but not required: a good electronic boost controller, boost gauge, exhaust gas temp gauge.

parts that will require fabrication:

the piggy back control unit wires into the 4efe engine loom requiring around 6 wires. (no 4efte ecu or loom required). the dizless e11 system and ems is far better/faster than the 4efte distributor type.

e11 4efe inlet manifold to house the 4efte inlet temp sensor or the 4efe original inlet temp sensor. (if the 4efte sensor is going to be used the plug for the sensor will be needed). keep the 4efe throttle body, this will hit the required 190hp.

4efte lower power steering bracket/mount to house the 4efe e11 power steering pump.

4efte decat pipe, to avoid the e11 front engine mount and front to rear engine mount support beam/cross-member.

full exhaust system 2.5inch to 3inch with high-flow cat for the best performance.

extended lamba sensor wiring to reach to the new decat pipe position. (use the e11 original lamba/o2 sensor).

ill put up detailed info of how id carry out all of the above modes. there should be no other plug swaps required. all other 4efe sensors will just swap into the 4efte engine and work fine. i will also put up info of how to wire in the det3 piggy back.

universal inter-cooler pipe kit cut to size and cleaned out before use.

mount inter-cooler core.

porting the exhaust manifold out.

porting/opening up the ct9b waste gate port.

air filter kit and piping.

things ill have to look further into on this swap.

the 4efte distributor/head mounting point, is there a cap/cover on the 4efe e11 to blank this off and mount the dizless coils in the distributors place.

i could do with you having a look here on yours to answer this question please.

EVERYTHING ELSE WILL SWAP OVER AND TAKE THE POWER.

ecu master det3 tuner how to wire into the 4efe dizless system. wiring diagrams wire colours and ecu pin outs to come.

how to install the 4efte intake sensor or the original 4efe e11 intake temp sensor into the corolla intake manifold.

you can see the added 4efte intake air temp sensor and threaded mount that is wielded into the e11 intake manifolds plenum chamber.

the sensor is a 2pin plug and can be wired in either using the toyota original plug or 2x small female spade terminals (speaker terminals)

the original wire will need extending in order to reach the new sensor position.

option 2: the original sensor mounted into the same point

this picture is how ive mounted the original 4efe ep91 plastic air temp sensor into the ep91 intake manifold. thew the manifolds are different the same approach can be used just mount it in the e11 manifold in the same place as the previous picture of the 4efte sensor. use sealant or and a additional sealing Oring.

inside photo

picture of the difference between the 2x sensors, these sensors use the same resistance to temp operational scale.

lamba sensor position in the 4efte decat pipe.

this pipe is bolted to the turbos exhaust side outlet and drops down the front of the engine to the exhaust system.

another option here is to cap/blank off this port and leave the lamba sensor unplugged leaving the ems ecu to run in open loop, but a de-cated exhaust system will be needed, also the engine warning light might be on permanently. .

also this is the pipe that will require fabrication to avoid the corollas front engine mount that is positioned and attached to the gearbox bellhousings front edge. this will foul the down section of this 4efte decat pipe.

the 4efte power steering modification.

this normally will come with the 4efte engine.

this bracket will foul the underside of the e11 4efe power steering pump, and the adjuster hole seen above does not line up with the e11 4efe pump bolt hole. the e11 pump bolt hole is around 1.5inch further in and also closer to the engine.

the 4efte bracket above is required to be used because the 4efte oil filter housing steps off towards this bottom power steering bracket. this bracket gives the oil filter housing the additions room needed.

now what i would do is to cut the bracket in the picture above so as to allow the e11 4efe pump to move freely and not catch this bracket allowing adjustment (it stops the pumps belt to be removed/replaced, so downwards movement). were the cut is required is at the tip of the adjustment hole you can see in the picture above. around 1inch from the tip of the adjustment hole (just anuff to remove/replace the belt).

this allows the e11 pump anuff room to move to remove/replace the belt when required.

now an additional bracket is needed to be made/fabricated (very simple) in order to line up the e11 4efe pump hole with this 4efte adjustment bracket hole.

this is a 3inch in length peace of inch wide flat steel bar with 1x 12mm hole at either end (2xholes in total) now welde 2x 12mm nuts together, now wield them to the flat bar inline with 1 of the drilled 12mm holes (so when a bolt is fitted/screwed into the 12mm bolts it passes threw the hole in the flat bar)

now bolt it all together the nut/nuts end of the flat bar bracket attaches to the rear face (oil filter side) of the 4efte bracket in the picture above, the 2x wielded nuts and the bar take up the space needed to alight the new flat bar bracket with the e11 4efe power steering pump.

fit the belt, have the new bracket (flat bar) fitted, but loose, place a heal bar under the pump so as to pri it upwards and put tension onto the belt, now just tighten up the new bracket bolts at either end.

IF YOU COULD GET PICTURES OF THIS PROCESS TAKEN IT WILL HELP THE LADS DOING 4EFE+T CONVERTIONS ON THERE UK EP91 EP80.

THIS ALSO WORKS ON THESE 4EFE VEHICLES/FACTORY POWER STEERING PUMPS.

-

-

looking good.

rebuilt time.

-

I just used putty on top of the piston, to measure the gap.

1 thing to watch out for is the valve springs going coil bound (spring coils touching). When going higher lift. Also under bucket Shims on the cam followers.

turboing a 4efe

in N/A E-Series Engine Discussions

Posted

are you using the additional 3-bar map sensor on the emanage.

thanks the reply and information this is the first turbo-ed NA ive had all my other car are modded turbos.