-

Posts

406 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by federalman

-

Decided to reinforce the clutch fork and ordered a reinforced clutch pivot and stage 4 white bunny clutch kit from competition clutch

-

It’s a super HX35. Bit of a weird turbo as it has a water cooled core and an 8cm turbine. Thanks for the kind words, I do try

-

Had a slightly different project to help with: machine a new water pump part in brass as the original steel had rotted and face an impeller for a TR7

-

Had a slightly different project to help with: machine a new water pump part in brass as the original steel had rotted and face an impeller for a TR7

-

Although the turbo and valvetrain will flow enough for the target horsepower I decided to smooth out the casting marks in the ports as the head was off anyway. I opened out the exhaust ports but the inlets were already as big as the gasket so this saved some time. Starting with the exhausts I’ve ported them, removed the casting residue and buffed them to 300 grit. I have polished them but haven’t cleaned the head yet to see how they’ve come out. With the inlets I removed the excess casting and smoothed them out buffing to 240 grit to aid fuel atomisation

-

With the help of the other half I got the head off, pistons and crank out. The bores are in great condition and will just need a good hone. Considering the life this engine led only 2 main bearings on the middle journals were damaged, they have damaged the crank though by the look of it a polish will bring this back

-

-

-

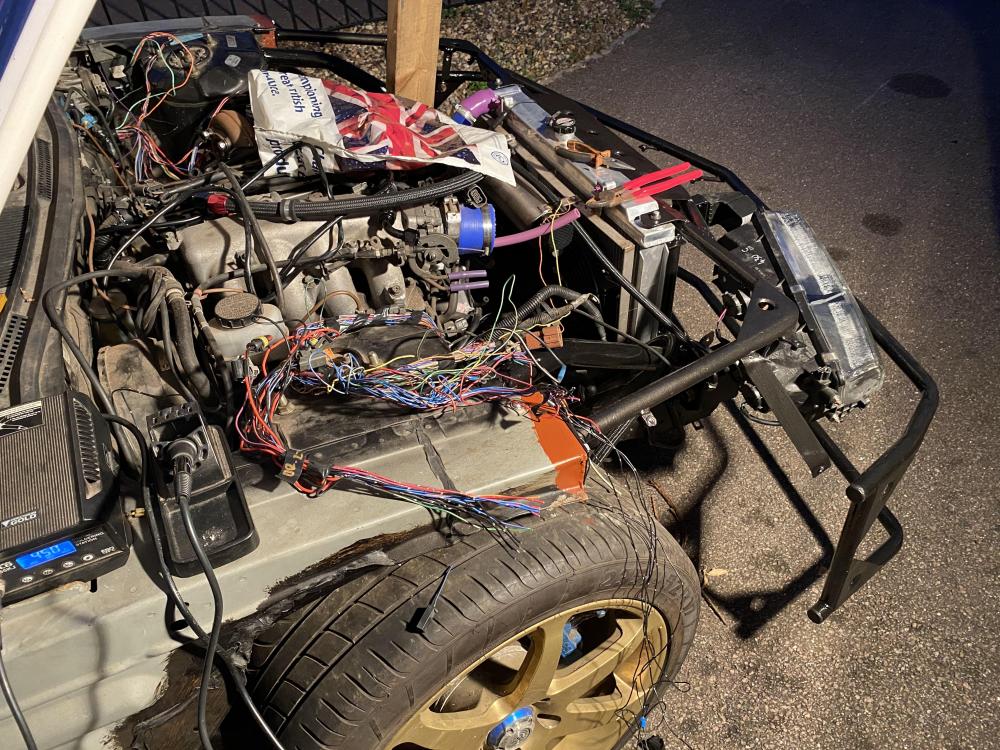

Well it’s been a while since I updated this thread so here goes, got a few bits to add but I’ve mainly been prepping for the engine to come out. So here it is: engine out

-

With the arches gone completely there’s no where for the fuse box to live so I’ve relocated it to the glove box. Dash came out to do the job properly. Air bag wiring, abs loom and air con was completely stripped from the car. The headlights and gearbox loom was pulled back through and rejoined and now completely misses the front drivers wheel. I’ve still got to order some battery cable to wire back in the alternator and starter motor and extend 3 wires as well as wire in a horn and the rear fog

-

Cheers, it’s been a long time in the making but finally getting it done

-

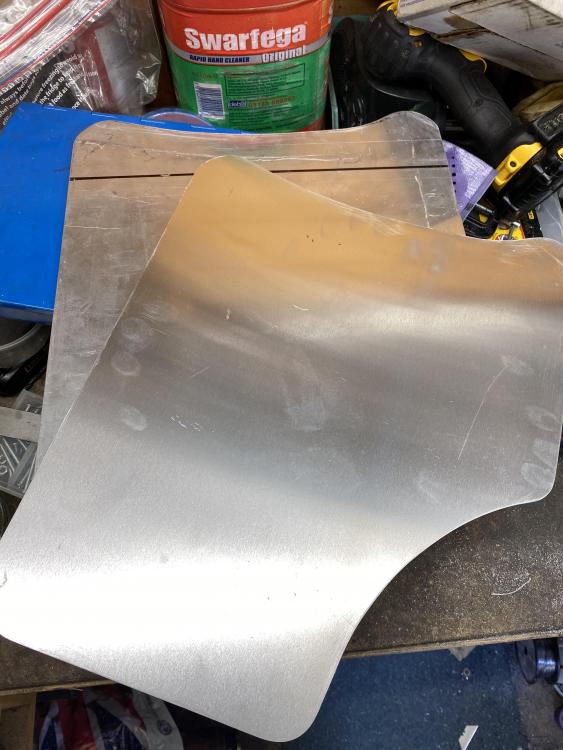

Decided to go for a rear wing low mounted. Made up some end plates for it, just need to clean them up and paint them satin black

-

Last of the intercooler pipes fabricated. Other than marking the gearbox wiring locations for the fuse box relocation the engine can now come out.

-

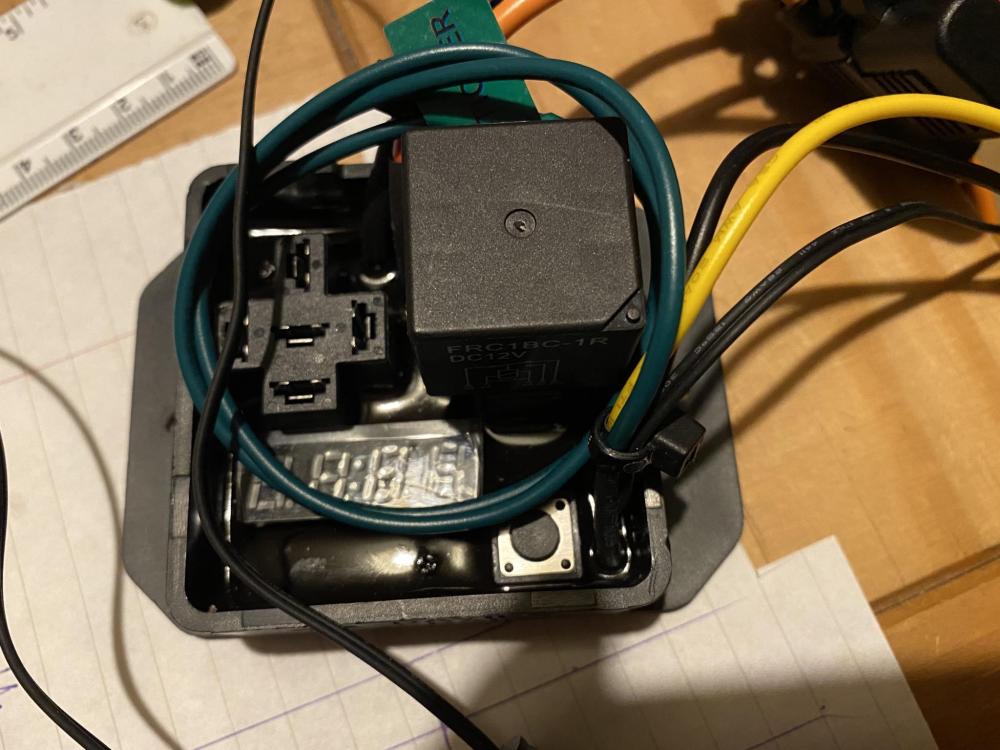

Wings prepped for some primer and finally finished the boot. Doesn’t look pretty but it’s as smooth as my limited bodywork skill can get it. Ordered a Davies, Craig fan controller. I was going to run the rad fans from the stock relay but it seems to be integrated with the A/C wiring and I’m aiming to rip as much wiring out when I relocate the fuse box.

-

-

Quite a bit of work done hours wise but not so much in the way of stuff done. Got the bash bar painted and fitted back on

-

Got the main supports painted up, I shall paint the rest of the bay when the engine comes out. Decided to add to the bash bar as it didn’t look right. Made up four more dimple die gussets for the outer corners. Got a coat of red oxide on it and will get some black paint on tomorrow. Just need to paint the main bar now.

-

Got the drivers side seat rail adapted to take the Bride seat. I also changed the mounting of the passenger bucket seat so it sits lower in the car. Gave all the parts a lick of Hammerite paint and these are now left to dry for a few days. Also made a couple of brackets to brace the manifold as I’d heard of s/s top mounts cracking due to heat and weight. Had some scrap 3mm stainless flat and 20mm angle which should help to solve the problem. I have started to move the fuse box into the glove box and remove a lot of the unnecessary wiring left in the car. The fans will go on to an adjustable fan controller instead of into the factory loom so all of the a/c wiring can now come out.

-

Yeh that was the aim with this car. I’m an electrician by trade but my old man was a sheet metal and fine limit engineer before going into electrical work so he’s taught me a lot and anything else was self taught. Unfortunately he’s no longer here to see the progress/interfere. It’s a testament to what you can do with some tools and researching enough about what you want to do

-

-

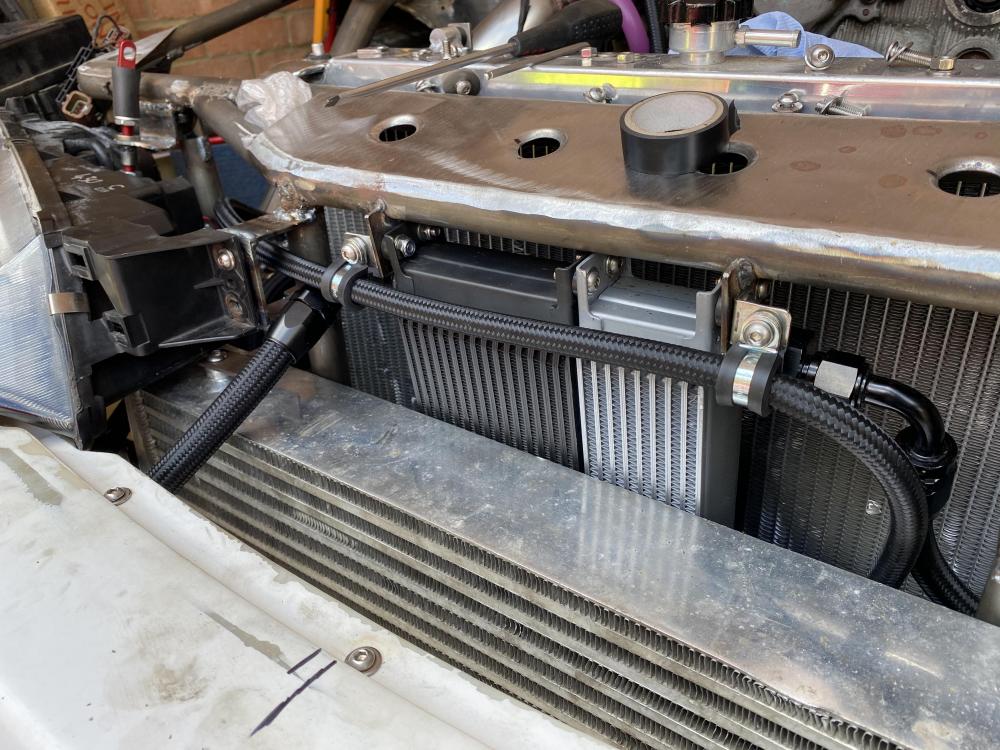

Got the oil and power steering coolers mounted and had to change the layout of the top intercooler brackets as it fouled the headlights. Started running in the power steering lines and I need to make some brackets for p clips to stop them from moving. Got the bonnet pins adjusted so the bonnet sits where it needs to as well. Decided to change the intercooler piping as I wasn’t happy with how it sat. I’ve lengthened one piece of the hot pipe and shortened the other part of it to move it away from the wheel. I have had to change the cold pipe as the turret to chassis bar is in the way

-

Started making the rear bash bar and jacking point. Got it welded together but it has bent slightly from being welded so I need to adjust the plan for it. At least it’s properly welded I guess. I notched part of it on the pillar drill but 2 braces needed to be botched by hand. Just needs tidying up and the final fitment

-

Got the last 2 tubes for the bash bar done and welded in. Drilled the holes at the back of the chassis boxes to stop the bar sliding forwards and rattling. Had to machine the tubes first for a nice clearance fit and these can be lightly greased to stop them from rusting. Finished all the ends with plastic end caps to neaten the tubes up.

-

Aerocatches fitted and headlight brackets welded in. I have 2 tubes left that attach the bash bar to the chassis legs. Think one of the next things to do is a rear jacking bar as I can’t get a jack under the diff with the Partsshopmax drop knuckles on it

-

Yeh have a look on amazon or eBay