starlet1991

Club Member-

Posts

93 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

malta

Recent Profile Visitors

2456 profile views

starlet1991's Achievements

Member (2/8)

-

Looking for a jam or blitz ecu for a glanza

-

Sam44 started following starlet1991

-

I am currently having an issue with no power in the stereo harness. In the plug shown below there is no power in both the constant 12v (yellow wire) and ignition 12v (red wire). I also found the indicated connector in the second photo identical to the one for the stereo. This is located on the drivers side footwell. Checked with meter for continuity and found that both connectors are on the same harness as confirmed continuity. Can anyone confirm if this needs to be connected to anything? Have found no loose plugs nearby. Would appreciate if anyone can post photos.

-

Bump

-

I am currently having an issue with no power in the stereo harness. In the plug shown below there is no power in both the constant 12v (yellow wire) and ignition 12v (red wire). I also found the indicated connector in the second photo identical to the one for the stereo. This is located on the drivers side footwell. Checked with meter for continuity and found that both connectors are on the same harness as confirmed continuity. Can anyone confirm if this needs to be connected to anything? Have found no loose plugs nearby. Would appreciate if anyone can post photos.

-

Can anyone share some photos of the oem earthing cables in the engine bay? Gone through a complete engine bay rebuild and need to be sure that all the earthing cables are installed.

-

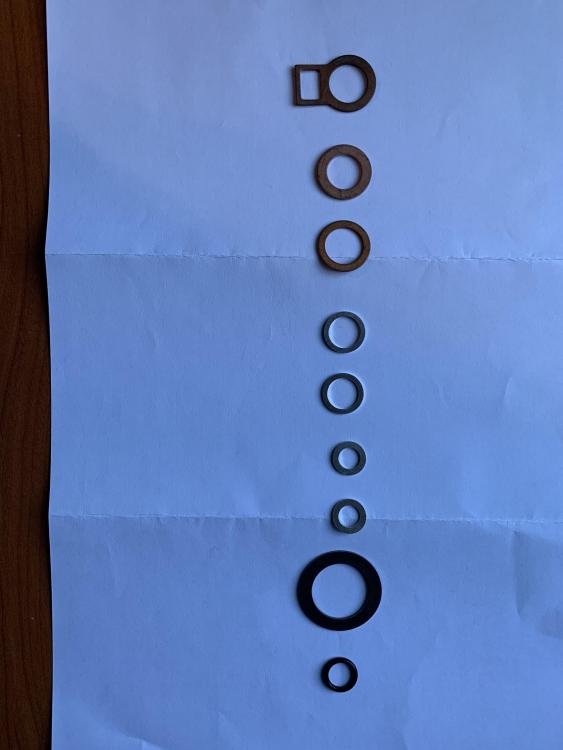

Should the release bearing provided with the orc clutch be installed as is? Or do you need to use the retaining spring clip found on the oem release bearing?

-

-

Looking for an aftermarket high flow fuel rail

-

-

Currently going through a forged engine assembly with the below specs: - blocked bored to 74.5mm and surface decked - wossner forged pistons - acl bearings - scat rods - arp main cap studs the block has been assembled using engine assembly lube and following tightening torques provided by arp. The assembled crank on block rotated very easily however when the rods and pistons were installed, it seems that there is too much resistance to turn crank. does anyone have an approximate value for torque that would be required by a torque wrench to rotate an assembled block? Could this be due to resistance of piston rings on freshly bored and honed bores? Which would then become smoother once piston rigs are seated in?

-

Currently going through a forged engine assembly with the below specs: - blocked bored to 74.5mm and surface decked - wossner forged pistons - acl bearings - scat rods - arp main cap studs the block has been assembled using engine assembly lube and following tightening torques provided by arp. The assembled crank on block rotated very easily however when the rods and pistons were installed, it seems that there is too much resistance to turn crank. does anyone have an approximate value for torque that would be required by a torque wrench to rotate an assembled block? Could this be due to resistance of piston rings on freshly bored and honed bores? Which would then become smoother once piston rigs are seated in?

-

jdmdhaka started following starlet1991

-

Looking for a Set of glanza headlamps in good condition