-

Content Count

404 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by federalman

-

-

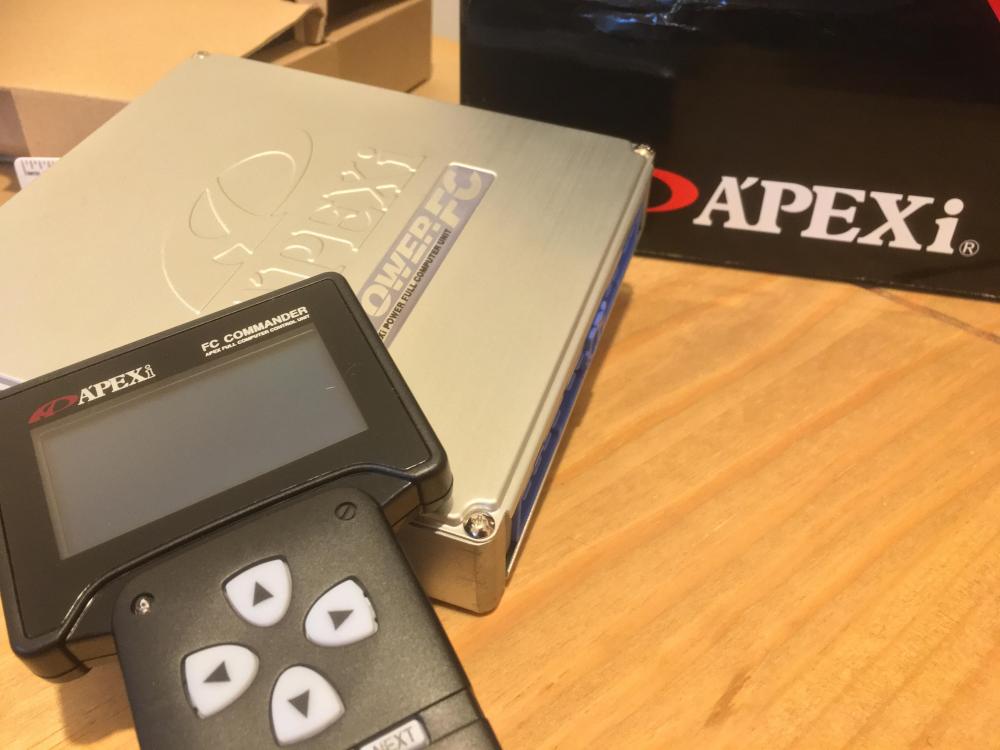

Got hold of a phone car holder that’s just the right size for the commander and ordered up some materials to make a bracket to fix it to the dash

-

-

Or perhaps not as it won’t let me upload them!

-

So quite a big update with plenty of pictures

-

You’re more than welcome

-

-

-

The head uses 34mm exhaust valves. These were originally the intake valves. The 40mm intake valves are from an unknown engine. As you can see the valve seats have been cut in by Triumph engine builders very close to the sides of the cylinder wall. The aluminium sticking out above the spark plug will be ground off with a carbide burr before completely polishing the top of the cylinder. The back of the valve seats have a very sharp angle to it so this will be reduced and smoother into the rest of the port before polishing.

-

-

If it’s been stripped down at all you can tell as the valves are massively oversized to standard. I’ll post the pictures later on as words don’t do these things justice

-

As it’s up for £6000 I wouldn’t imagine it’s one of the original race engines. These on their own would easily make £10,000

-

Four other engines are known, I would imagine my brother in law would have an idea. One appears to have got lost however.

-

So on to the history of this engine and it’s past as well as it’s present day ownership.

It’s an ex works rally engine from 1978 Triumph TR7 V8. There were 3 cars entered that year, each having a spare engine the idea being the engines could be swapped between all cars. During this season the TR dominated the circuit with nothing to catch it. The car it now sits in is one of twenty rhd TR8s and it is believe to be one of the last produced. Of the six only five have actually been found, so the last one could well be out there with an owner who has no idea why their TR is quicker than others.

The heads themselves have come straight off the factory floor and were not a special casting. However these were modified slightly with extra oil galleries, enlarged push rod guides to fit upgraded push rods and extra bolts to attach the heads to the block. As a result some of the exhaust ports are completely out of line with the exhaust gaskets. Before polishing I will be gasket matching these and opening the insides out slightly whilst following the original lines of the ports as well as reducing the sharp angle of the top and bottom. The inlets will be gasket matched, casting marks removed and left slightly rough to aid atomisation of fuel.

When dyno’d this engine was making over 350 hp at the rear wheels, with a completely ruined clutch and SU carbs. The rev limit currently is around 8,000 however the engine is strangled by the heads and has in the past suffered from valve bounce which is common with Rover V8 engines. With upgraded valve springs and titanium retainers this problem can be eliminated.

The valves in this engine are quite a combination. The 34mm exhaust valves are in fact the standard inlet valves for this head. The 40mm inlet valves are from an unknown engine. You can see how close the inlets were machined to the cylinder by the Triumph engineers when this engine was originally built. The piston rings in this are not standard as they are thinner and are now extremely hard to come by. The timing chain is an American imported item.

I shall upload some photos of the work so far later on. Thanks for reading.

-

So this is an unusual one for the forum but one that I thought would be worthwhile posting up so I hope you all find this interesting. The engine in question is a Rover V8. Produced for the last 37 years in various capacities and being fitted in the TR8, Land Rover’s and TVR’s to name a few. I write this thread to document the on going work to restoring a classic British icon of the 70’s and 80’s and it’s day to day use.

Having finished the porting and polishing of my TD04 it has been my privilege to be asked to carry out some major porting/correction work and polishing of the intake and exhaust ports as well as the top of the combustion chamber. The car is owned by my brother in law who until recently has been working for my father in law restoring classic cars as a business for many years.

When dyno’d this engine was making over 350 hp at the rear wheels, with a completely ruined clutch. To put this in perspective these engines would normally produce around 150 hp. The rev limit currently is around 8,000 however the engine is strangled by the heads and has in the past suffered from valve bounce which is a common problem with these. With upgraded valve springs and titanium retainers this problem can be eliminated.

The engine in its original form is far from standard and to say the history behind this particular engine is interesting is an understatement. The next post will give a brief run down of this and a bit of the spec as it came out of the Leyland factory.

There will be many updates as I progress through the work on it. I do have some photos and spec to post, however the next write up from me will be the history behind this and the story so far.

-

Yeh he is. Has an S15. Him and his wife have an s14 and a fairlady z

-

-

-

-

-

Been a while, had quite a lot going on of recent having moved a few months back and building myself a workshop. Rebuilt the TD04 and ported the turbine housing whilst I was at it. Still stinks of burning oil however. I suspect the oil return is causing the problem as it’s always been a bit long and is currently squashed slightly causing a restriction. If anyone has some suggestions as to anything else it could be I’m all ears. Got it balanced though and there were no issues of it leaking oil during that. Anyway here’s some photos

-

Found mine ages ago. It was not pretty. Managed to find a replacement from mister auto. Think it was about £11

-

Finally got round to ordering the power steering fluid cooler this week and it arrived yesterday. Managed to finish the framework, made from 3mm stainless. Plenty of strength to it and it won’t rust. Currently waiting on some 6mm stainless rod from China as I mistakenly ordered it from there but it was cheaper than getting it from the UK. This will then be welded to a plate and fitted inside both front wheel arches.

-

I don’t get to spend nearly as much time on the TIG as I’d like to but I do alright for an electrician! I think it’s a nice touch if you can say you’ve done all the fabrication yourself.

Nice S15!

-

Oil cooler turned up today from good old china. About the same price as just the block adapter from Tomei so I was skeptical if it but I was mainly interested in the adapters and lines. The core is actually very good so no need to buy a decent core. I’d say that’s a win. Drilled all the holes for the mounts so just need to weld it all up

Triumph TR8 V8 build

in Other Motors Progress Blogs

Posted

As you can see with the standard casting the ports aren’t even straight and are miles too small compared to the gasket. These have now been opened right out and gasket matched.![]() The fact this engine produces 200 hp above standard with the heads as they are is quite surprising.

The fact this engine produces 200 hp above standard with the heads as they are is quite surprising.

This is the start of the porting process.