-

Content Count

2353 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by Pikey009

-

-

-

-

-

-

-

Thanks for the comments, it’s coming together now.

Yeah apparently so ref the rods. The sump will be off soon so I’ll have a look

-

Cash waiting

-

love this thing mate, get some more updates on the go

-

Mine need replacing, where the sump has been leaking has gone on to the wishbone and corroded it. I might be able to wire brush and paint them but would rather just renew them really.

-

Cash waiting

-

Are glanza and EP82 wishbones interchangeable? If not then where can I get 82’s from?

-

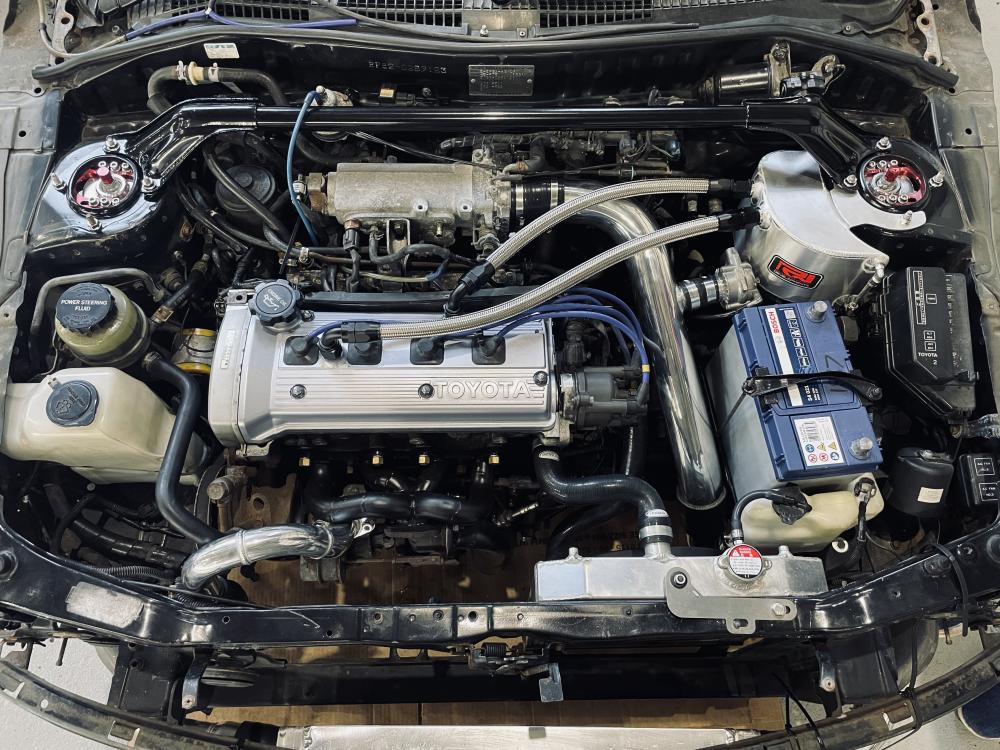

I’ll mock up the brackets tomorrow. I also trimmed the intake pipe so I should be able to get that mounted properly too- the air filter needs a support bracket making.

next week I’ll be tackling the leaky sump

-

-

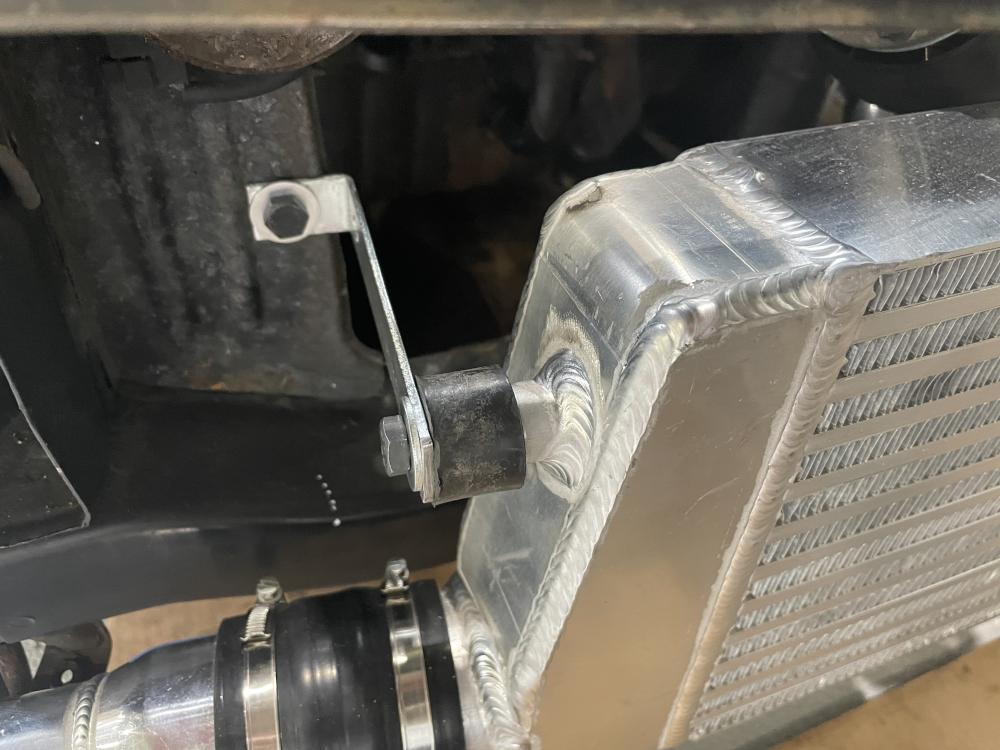

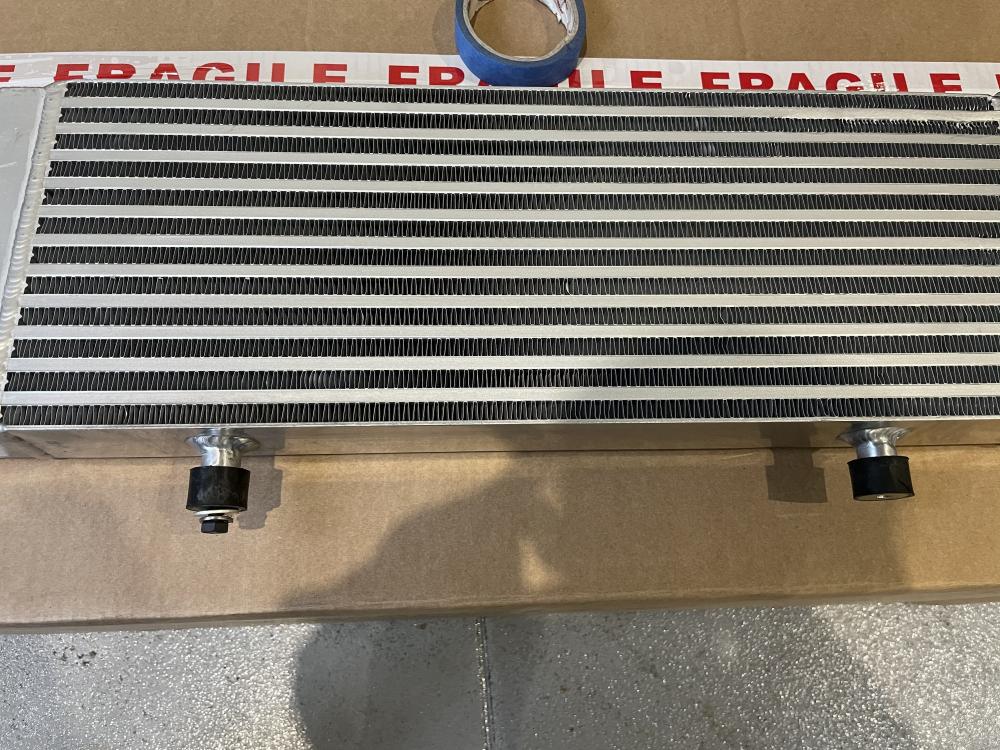

I ordered some threaded rubber dampers from eBay. The idea is that they will provide a little bit of give rather than solid mounting the core that would transmit shock through the threaded mounts. I had to trim them a little so that they could sit flush.

Tip: if you’re trimming a thread, wind a nut on before you begin to cut. It can be used as a guide, stops you damaging other threads and once you’ve cut through, as you wind it off it re-cuts the original thread so that it’s easier to wind in to where ever it’s going.

-

-

-

-

-

If you get no joy, i've got one mate

-

Those decals are the best I’ve seen mate

-

-

-

-

Jase - Mk2 GT

in EP80/EP82 Progress Blogs

Posted

So I’m suspecting the sump is sealed and the crank oil seal is leaking as it only drops oil when it’s running and hot.

As the seal sits behind the timing gear, I thought I may aswell do the whole timing kit along with the water pump.

I also noticed a tiny bit of weeping from the turbo oil feed banjo connection so ordered the copper washers which have cured the issue.