-

Posts

1024 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by SpikeyJp_68

-

Valve stem oil seal removal and re-seating valves

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

Side to side movement ? Is it possible to replace them at home ? -

Valve stem oil seal removal and re-seating valves

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

I'll put a pic up of my valves tomorrow Not the valves the guides -

Valve stem oil seal removal and re-seating valves

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

That's spot on cheers mate -

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

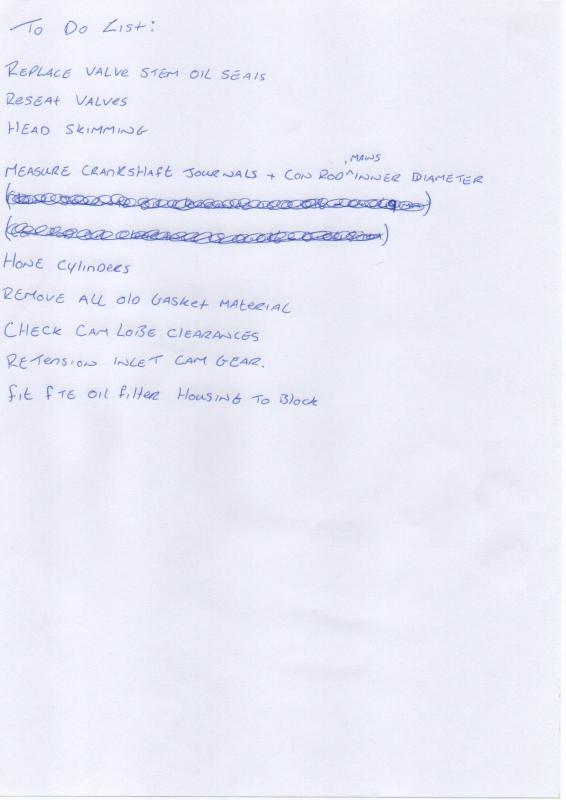

Head work has begun.. Plan on cleaning the valves tomorrow at work then I'll have to wait for the die grinder I bought to arrive so I can smoothen the inlet and exhaust passages along with the combustion area. Then I'll reseat the valves and then send it off to the machine shop to be skimmed and re-assembled -

Don't say give it to a machine shop, I wouldn't ask if I didn't want to do it myself Anyway, what way do the seals come out ? I'd imagine they lift up with a pair of long nose pliers or similar but they seem fairly firm when I tried that. What's the best way to do it ? - I have the valves & springs etc. Out of the head just need to remove the seals Also, when reseating the valves, will I grind them in using the old seals or new ones or is it irrelevant ? Many thanks in advance, Regards

-

Can you use a FE crank pulley on an FTE engine

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

Off topic again I know but how is it with no power steering ? Better control ? Just don't like thinking of parking -

No use if from a GT unfortunately. Just got sorted in the past 5 mins. Can be locked if needed

-

Can you use a FE crank pulley on an FTE engine

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

Seems to be done quite often in that case. A bit off topic here, but I take it the advantages are minimal of running a lighter (4efe) pulley as compared to the heavier (4efte) pulley ? -

Can you use a FE crank pulley on an FTE engine

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

If the wizards can do it, it will do for me -

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

Ended up with runs the last time I painted it.. take 2 Hopefully it'll end up the same colour as my cam cover -

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

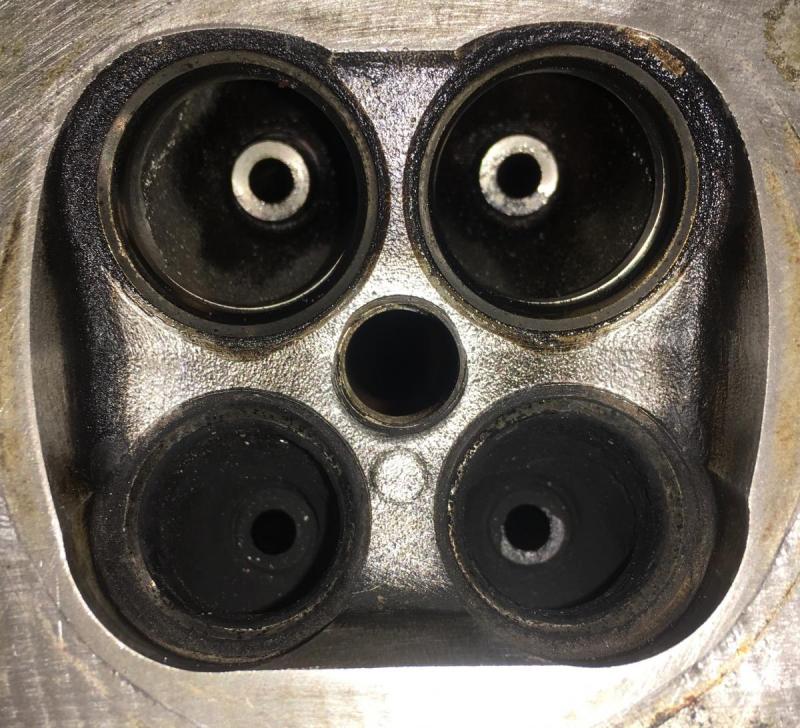

Crankshaft pulley has been removed and the engine now looks like this That's a bonus then, thought it increased lag quite a bit -

Can you use a FE crank pulley on an FTE engine

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

-

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

Air gets out but the compressor wheel isn't slowed down by having air shoved back out through it -

Can you use a FE crank pulley on an FTE engine

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

Dampened that's what I was looking for. Read through that, sounds a bit worrying but just heard of people doing it before with no problems Well that's good to hear. Would save me getting and replacing it with an FTE one -

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

Sounds nice, but you've to build all the boost back up again -

Read a few bits about this before but never got a definitive answer. Is a FTE crank pulley 100% needed on a turbo engine ? I know the FTE ones are harmonically balanced but what happens if I stick with the FE one ?

-

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

For my own records: Tourque specs & limits http://www.toyotagtturbo.com/forums/showthread.php?27569-4EFTE-Torque-Specs -

Top lad Colin I'd imagine a pair of vicegrips/water pump pliers would work ? Won't be needing it anyway Cheers mate

-

Put extra pressure in your tyre ( not exceeding the max on the side wall) and go at it with a rubber mallet. Hit it on the outside, inside and the tread on full lock. After that I don't know. Best of luck with it and don't forget copper grease when putting it back on !!

-

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

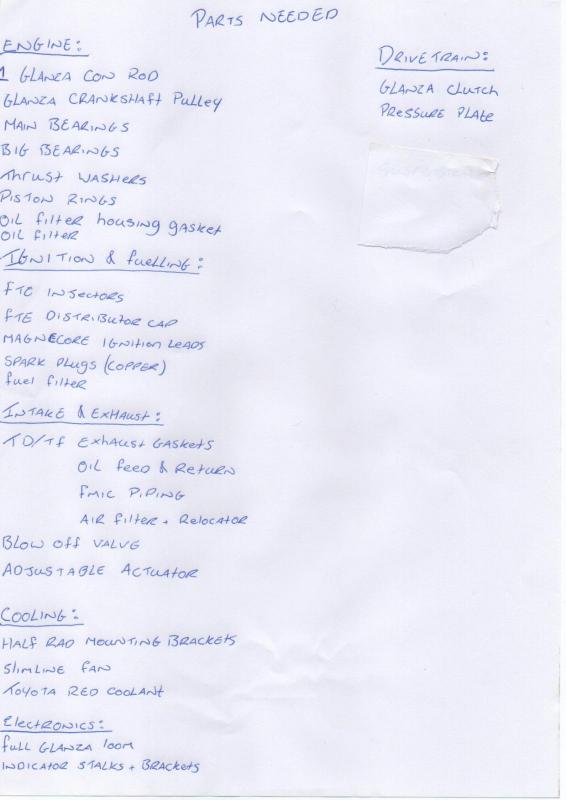

Got engine #2 yesterday to save me taking my one out. Started like this And is now stripped to just the block & crankshaft. Will take the crank pulley off tomorrow at work becuase my impact decided to pack in. Plan from there is to clean it as much as possible, hone the cylinders, measure my crank journals( big & main) then it can be snuck inside (for a clean environment) and built up after that. As for the head, I'll be doing the valve stem seals and I've bought some valve lapping paste and a stick so the valves will be reseated aswell. Will be resurfaced before going on. I'd upload some more pics but it says each file is limited to 2MB which I've never had before or at least I don't remember it -

Does the centre stud come out and will I need to drill holes any tap them ? Or will I get away with a gasket and sealer ? Thanks in advance.

-

Bump... I was given one but now I've gone to dig it out I can't find it....