-

Posts

1024 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by SpikeyJp_68

-

Crankshaft big end journals measuring over 40mm ?

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

Ah I see so for example the standard they used might be 1" +/- .04mm ? I've ordered plastigauge anyway so that will confirm if I'm within spec or not -

N/a and glanza driveshafts ?

SpikeyJp_68 replied to SpikeyJp_68's topic in Drivetrain & Transmission

That's what Toyota told me anyway. Said they had to get them from Japan even still it's a bit ridiculous. -

Looking good pal

-

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

Used a shit tonne of wd40. I thought myself they looked a bit 'flakey' almost -

Crankshaft big end journals measuring over 40mm ?

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

It never came with a standard so that's why I sent it to the machine shop. It's a 1-2" micro calibrated at 1". It looks like I'll be sending the crank off to them anyways -

Crankshaft big end journals measuring over 40mm ?

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

It's imperial. 0.0001" Converted via google -

Hi guys, Gotten round to measuring my crankshaft and I got the following numbers: No.1 = 40.045mm No.2 = 40.048mm No.3 = 40.048mm No.4 = 40.043mm The limits are 39.985mm - 40.000mm so how is this so ? Had my micrometer calibrated the day before in a machine shop and double checked my measurements which came in at +/- 0.0002" of the originals. Any help appreciated

-

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

-

N/a and glanza driveshafts ?

SpikeyJp_68 replied to SpikeyJp_68's topic in Drivetrain & Transmission

Cv joints themselves are 800 Euro a piece from Toyota. Just had new cv boots put on so they're good to go really. I will be for the time being with an FTE flywheel and clutch -

To do it properly you'll need to remove the head. It can be done at home if your confident enough. As for keeping everything together you'll need a box like this and label the different sections in1 in2 ex1,2 and so on You'll also need a valve spring compressor to get the little collets out that keep the retainer in place.

-

MISS,STRESS >>> mister koni yellow

SpikeyJp_68 replied to 5e colin's topic in EP80/EP82 Progress Blogs

I'll wait and see how you do yours and follow that becuase I can see myself making a mess of it -

MISS,STRESS >>> mister koni yellow

SpikeyJp_68 replied to 5e colin's topic in EP80/EP82 Progress Blogs

Let me know what it's like pal. Just bought the same kit myself -

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

I'll have to go over them again with some fine grit for 2-3 mins per valve. Took about 2 and a half hours. Exhaust valves were badly pitted -

Don't waste your time with a ct9 upgrade. Wait and go for a td/tf turbo or a ct12/9 hybrid that Colin suggested

-

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

-

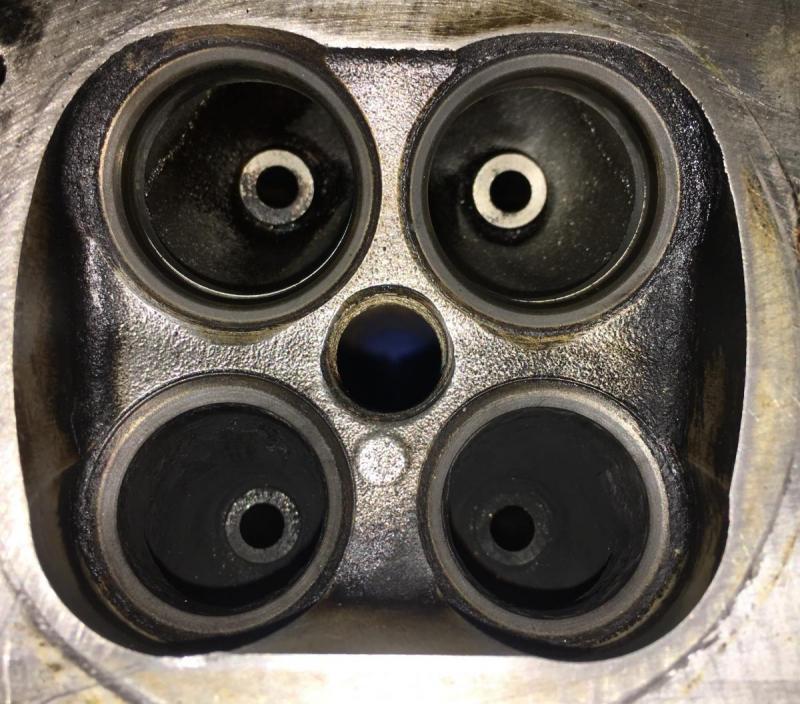

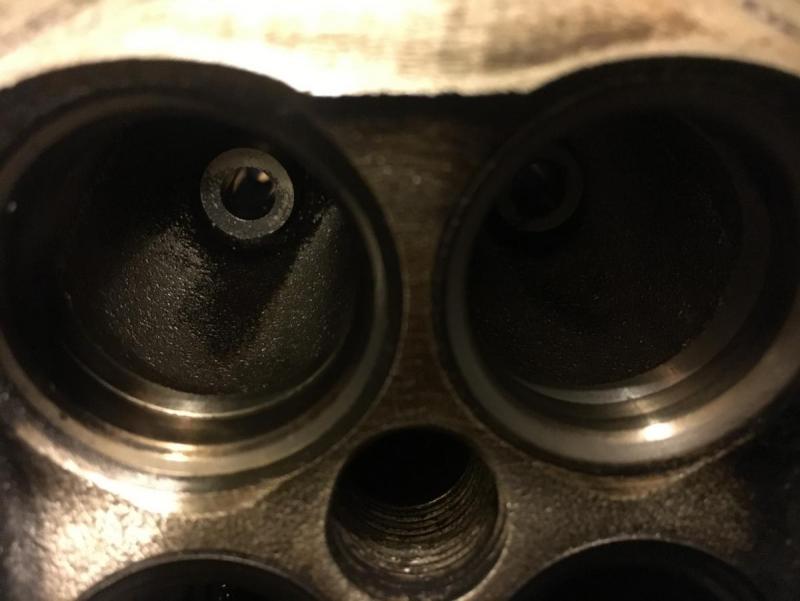

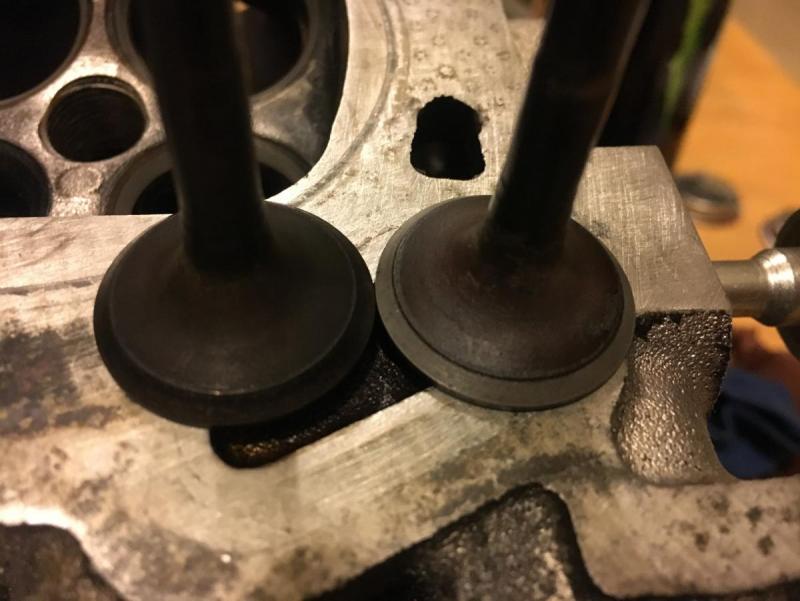

Valve stem oil seal removal and re-seating valves

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

They've been seated. Intake valves tool about 7 mins each start to finish as they were in pretty good condition anyway. Seated V non seated On the other hand, exhaust valves took about 15 mins a piece becuase they were quite badly pitted. I ended up doing 2 runs with coats and 1 run with fine. As before, seated V non seated Now they look like this ! Took about 2-2.5 hours in total and is quite therapeutic once you're properly set up for it haha -

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

I'll let you know about time and the condition of my hands -

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

-

Valve stem oil seal removal and re-seating valves

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

5-7 minutes of actual grinding is what I was told. I'll give one a go tomorrow starting with coarse ending with fine and go for a 1mm seat as Colin says. I'll time it start to finish so from applying the coarse grit to removing the fine grit and I'll report back with pics and a time -

-

Valve stem oil seal removal and re-seating valves

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

Only way to find out is to crack on and do it I suppose might give it a go tomorrow and see how I get on -

Valve stem oil seal removal and re-seating valves

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

I've bought a valve lapping stick, I've read it's not the best to do with a drill -

Valve stem oil seal removal and re-seating valves

SpikeyJp_68 replied to SpikeyJp_68's topic in Engines

That's okay, I'll check them though -

Should just pull out mate. You could break up the grommet with a small screwdriver as they're only cheap

-

Joe's 98 starlet full Glanza rep TF035HM - final bits

SpikeyJp_68 replied to SpikeyJp_68's topic in EP91 Progress Blogs

will be going that aswell Colin