-

Content Count

1487 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by Sam44

-

-

I've got a C63 or c64 out of the lotus 2zz.

I've started to strip the box today and have found some differences that are going to course me some problems. the main difference is the final drive differential drive shaft diameter is larger that just at present I'm stuck on, and these will not take the starlet drive shaft cups. If any one knows of any starlets running this box, or a cup to fit the box and the starlet shaft or CVJ otherwise I will have to get a final drive diff gear made at work to house the starlet lsd unit. The lotus and Toyota C63 & c64 boxes have much better lsd units and stronger cup stubs.

The good news is the 6th gear is thicker (in width) and the final drive gear is alot thicker against the c160 Levin box I have here.

I've managed to rip the rear gearbox mount off the c160 box last week. Practicing my launch in the dry.

I'm on 165 wide tyres so I thought I'd be safe. I hit just over 5sec to 60mph. @1bar on a tdo4l 13t hyb around 210hp (yet to be dynoed)

-

-

-

Good to hear some feed back on the coil overs. I was recently in a ep82 that had BC coilover fitted. I found the ride to harsh for the road, For me.

Looking good.

-

Waw stunner.

Fair play to you. On this GT MK3 I'm saying. (I'm still getting not known my GT models)

-

8 hours ago, Giannis said:

Thanks a lot

I've been out at my mum's most of the day helping out. I'll get you these pics first thing in the morning.

What angles and pannel do you need pics of?

-

I was wondering about the fitment of the caps. it's hard to buy caps separately from the block as there normally inline honed together alot of the engines I work on have snapped off crank caps being produced as part of the block.

I'm going to hold onto the 5e. This might be the engine for me to push I've just bought another starlet shell last week also.

Let's build some little rocket ships.

-

51 minutes ago, mycars12 said:

Many people in the U.S. have used 4e and 5e engines and 300 to 400whp is achieved with stock caps. There is even a 524whp turbo 5e that lasted with the stock main caps but when pushing that power many things start to go wrong. The main caps were not the first to give.

We might have to start another topic here on this subject sorry Gavin. Yeh I believe the 5e has better stronger caps out of factory than on the 4e I believe these break on the bridge heel is thinner. Just from the information people have shared with me. I do have a 5e block here and I'm waiting for a 4e engine to turn up so I can start to see the differences.

If you have had this happen to you on a 4e feel free to message me.

But send me any links you have and people to talk to running big power levels. Definitely room to gauge more information. Before I embark on a 5e or 4e forged build.

Thanks for any info guys.

-

I'm also very interested in this topic?. I've tried messaging afew people ho ran these tfo35 turbos but I didn't get any replys. As I got the manifold fit ments wrong on a recent ct9 hyb thread I'll see what I can find first.

I've run the 14412aa100 49377-04000 tdo4l standard turbo at 8psi, on a 5efe ep91 inlet manifold and a zisco ram's horn exhaust manifold external gated on a electronic boost controller 4efe ep91 engine cams. Pressure build was around 3krpm and came on full boost by 4250rpm. The only reason for this turbo was to check my hyb against a stock turbo, I picked it up for 30quid really good condition.

-

Yeh mines a uk cd sunroof model. 5door. I will be back home tonight I'll put some up.

-

Welcome get a build thread up. It's always good to see other people's work.

-

What colour are the wires on the three pin plug.

Spoiler looks smart. Really nicely styled

-

2 hours ago, Gav Missen said:

Ah cheers bud it was leading up in to that area! I think that’s what I am going to do source all the parts then get my local engine builder to do the rest is it work getting the crank ground .25 with the overaized bearings or just leave it as is if all is ok?

mom thanks for the caps info I’ve only seen a handful of people use them I guess it’s more of a if you can afford the extra it always helpsYeh as said it's only 1 persons advice that can be helpful to another. I have spoken to around 30 people at present which have warned me about running around 300hp due to all types of failures, not just cracked main caps. It does seem to be a upper level limiting factor.

Saying this as a percentage of these people more than 25% have had caps fail. Just saying you can make up your own mind as to how high or low this figure is.

All in the UK, which is very interesting. It would be good for me to hear from people out side of the UK.

-

1 hour ago, BurtEP82 said:

External wastegate is a Tial MVS 38mm. It has the option of water cooled but I’m not going to use it yet. May well do once I know everything is running right. I got it from tuning developments.

Nice. Great location to show it off. Mine is the tail air cooled but at present it's under my radiator where it can't be seen at the end of a long pipe. I'm going to relocate this to a better position very soon where it can be seen.

-

I'm definitely interested Rob send me a copy of the warranty if possible. And good points from akyakapotter all of which I also take into consideration

-

Sorry Gavin about this game of ukso tennis on your build thread. There will always be difference of opinion on even how to research your build. Rob you asked me for evidence and I have given it you. I'd suggest to Gavin to get you to build him an engine with a full warranty for 300+hp if you can do this I will have 1 as well.

-

26 minutes ago, RobSR said:

Nice progress so far.

The black box you mentioned in your pics above is for the indigo dials you have.

Josh has given you good advice on the engine build.

Sam, can you show the evidence of ‘alot of engines over 300 cracking caps’? I’ve seen one and have run 460bhp on stock caps without issue.

Gav, for your build you won’t need billet caps.Near every other pro starlet tunner I've spoken with Rob has warned me. So why you don't know I'm not sure. All I can say is phone some high up starlet engine builders and ask there advice on engine spec for target hp.

http://www.tuningdevelopments.uk/product_info.php?products_id=3314

As stated 250ftlds on a 4efte is around 300hp. as stated in my previous comment.

These are regarded along side racetech and fensport as the best starlet tunners in the UK.

And let me not forget zissco hos work on the quarter mile strip is legendary around these cars and yet to be repeated.

-

You tube how to are the best option. Running an external waste gate on a electronic boost control for the best results again use good equipment for reliability and power. The cheap eBay equipment does not last.

-

Yep either of these turbos are a better road option you can build your own tdo4l hyb. get a 13t billet 7+7 compressor wheel and a 11blade exhaust turbine. You will have to use a super back seal kit £30 and get it balanced £50 to £100. Then port out the exhaust housing from the manifold mount down to the exhaust turbine shell.

(You can get up to a 20t billet compressor wheel and housing but after looking at Dyno graphs the spool lost and back pressure are not worth going any bigger than a 17t compressor but again because of the compressor size and weight difference it affect spool up)

The 7+7 13t is a great option only slightly heavier but alot more air flowed against the standard 6+6 cast wheel.

Saying this search this site. There are alot of very knowledgeable people on here that can give you great information on setups and turbos to suit what you want from the car.

-

-

20 minutes ago, Gav Missen said:

What power did you make with the 16g bud any videos of it? Are you on about the billet end caps they do?

No i got to 6psi then the surge in power/spool was to much for the 4efe I was worried about bending a rod. Very agresive, and because of the late turbo spool up requires to be aggressively driven. All the things you don't want for reliability on toyota e series engine.

The c160 box does suit the bigger turbo better on the roads.

For good quarter miles times you want no less than a td05 20g hyb I was reading animal GT used a td06 on noss to get his times. Around 11sec

-

On 4/19/2020 at 2:57 PM, stevie82 said:

Or instead of using 4efte ecu u could greddy emb and have it mapped to run 0.6 bar, using a tdo4 turbo would be better for controlling the boost as u don’t want it to creep and melt the engine. Are u in Bolton?

Yep another option and a td04l is a much better turbo running lowwer charge temps safer also producing more torque. Run a large external waste gate reducing exhaust back pressure and temps ive found the zisco ram's horn to spool the tdo4l really well, plus you can get these quite cheap. This with the tail waste gate and jap speed exhaust with a high flow cat make a great combo for great full rpm range power.

You can stay with the starlet inlet manifold also or with the tdo4l go with the better tubular corrola inlet producing an even cylinder power balance and fantastic low rpm torque and hp this will really kick off the td04l spool up times. Making for a monster slaying little car. Very hard to beat at relatively low boost levels. Hitting around 190hp.

You will need a updated clutch the 4efe 200mm clutch slips bad around 115hp to 125hp

But you can get uprated 200mm units like I'm running or use the heavier 212mm 4efte units with the 4efte flywheel.

With the tdo4l I've found you can control throttle and wheel spin very good making lsd an option and not a requirement. The ct9 is the opposite.

-

I bought the car off a starlet specialist. Ho was running it on track at 200hp+ power levels for 2xyears. But he documented the full build and his research and he passed it on to me.

He stayed 4efe ECU because it has a better tps and fueling map. This allows you to not bother with the wiring loom and dizzy and coil and map sensor.

The det3 piggy back looks easy to use and can get the fueling required on the 295cc 4efte injectors.

Also there is the hks fcd aprouch cheapest option on a fuel pressures regulator and bigger injectors I'd go pink 4afe or 7afe units no bigger use a nock sensor gauge like on my build thread and wide band gauge to setup the fueling. But I'd go no higher than 5psi boost levels. Also use a exhaust temp sensor on cylinder 1 this produces the highest temps.

1 of the first mods on the 4efe is reducing engine running temps. So 68deg thermostate and remove the throttle body coolant pipes.

-

I'll get some pictures up very soon. I just need to tidy afew weilds and mounts the map sensor with screw to the manifold instead of zip ties lol. I was trying different positions in the plenium and measuring map sensor response to throttle position for fueling response. With the best position closest to the back of the throttle for reaction time but this can create a sensitive throttle pedal if you run a single large throttle body. The twin plate throttle I run has stopped this and is giving great throttle\boost control on the foot as well as great power build.

I'll get some pictures up very soon. I just need to tidy afew weilds and mounts the map sensor with screw to the manifold instead of zip ties lol. I was trying different positions in the plenium and measuring map sensor response to throttle position for fueling response. With the best position closest to the back of the throttle for reaction time but this can create a sensitive throttle pedal if you run a single large throttle body. The twin plate throttle I run has stopped this and is giving great throttle\boost control on the foot as well as great power build.

The manifolds you mentioned with the center feed like the acis on the 3sgte are alot better for power deliver. Plus if you look at the 3sgte unit it has 2xrunners feeding 1 cylinder this allows the manifold to head acis butterflies to control low rpm air velocity this system beat Honda's VTEC in torque levels with the 3sgte engine having a long stroke producing crazy torque on the high reving K20 and b series engines.

The 3sgte engine is 1 of the best high powered units of the last 30 years for its size.

The time delay on the standard map sensor against throttle position is crazy due to the vacume pipe length and manifold position and pipe diameter and the inline filter.

Be ready for the sharpness of the throttle if you change this. Its really very impressive. Use a rubber buffer placed in-between the manifold and map sensor if you are mounting it directly to the manifold because engine vibration can be seen on the signal its that sensitive. The rubber buffer does stop the vibrations signal error.

Moving onto the water pump I'm removing it soon replacing it with a fully electrical unit that has a controller monitoring engine temps I'll run this with a restrictor plate instead of a thermostate to produce required engine block pressures. The reason is I can't count on the standard water pump I'm getting alot of fan belt slippage coming on boost. I can also find best engine temps for best power normally found around 50 to 70degc. I can also up this in winter to give better in cab heating and defrosting. It also removes the risk of a thermostate failure.

I'll take some pictures of what was done to improve the standard unit which has a very poor open back impella design.

At present I'm working threw the standard factory productions errors in the system. There's alot of them.

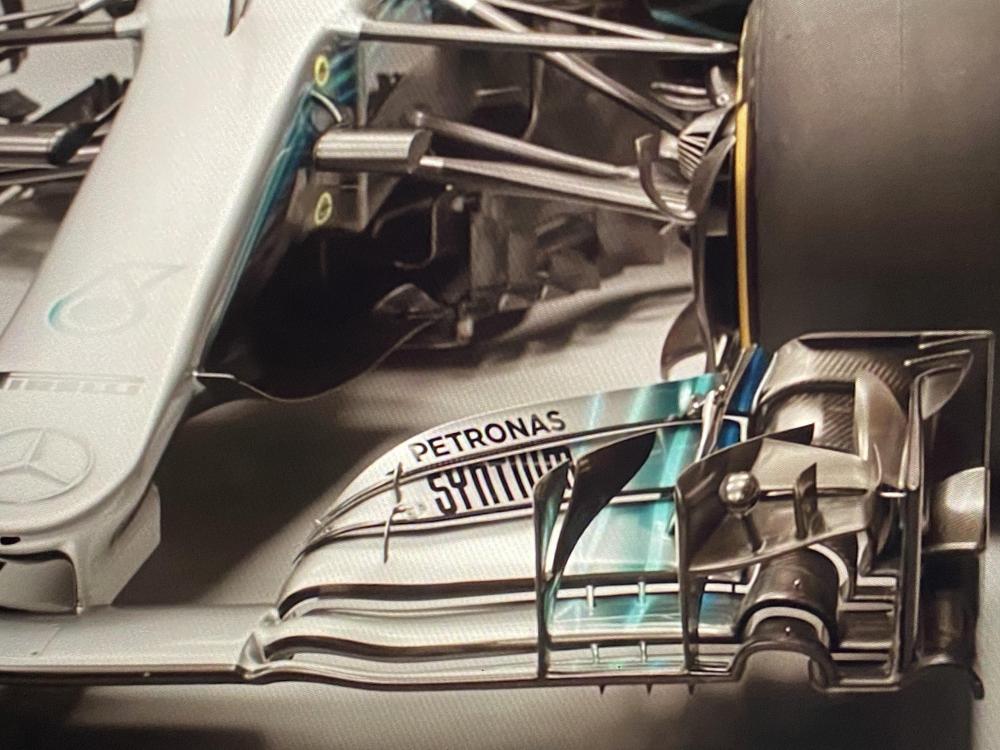

Picture above: the great 3sgte intake design.

Front mount intercooler

in Intake, Turbo & Exhaust

Posted · Edited by Sam44

Looking now. Always good to expand the know how.

Yeh I'm running 2x90deg bends into to core so definitely needs improving. Thanks for the information.