-

Content Count

1487 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Store

Calendar

Posts posted by Sam44

-

-

Great mod this. The throttle body is all adjustable on these with good low flow increases to be had.

-

Very true gee.

I didn't even notice the engine angle.

But yeh it's tilted.

Nice spot.

-

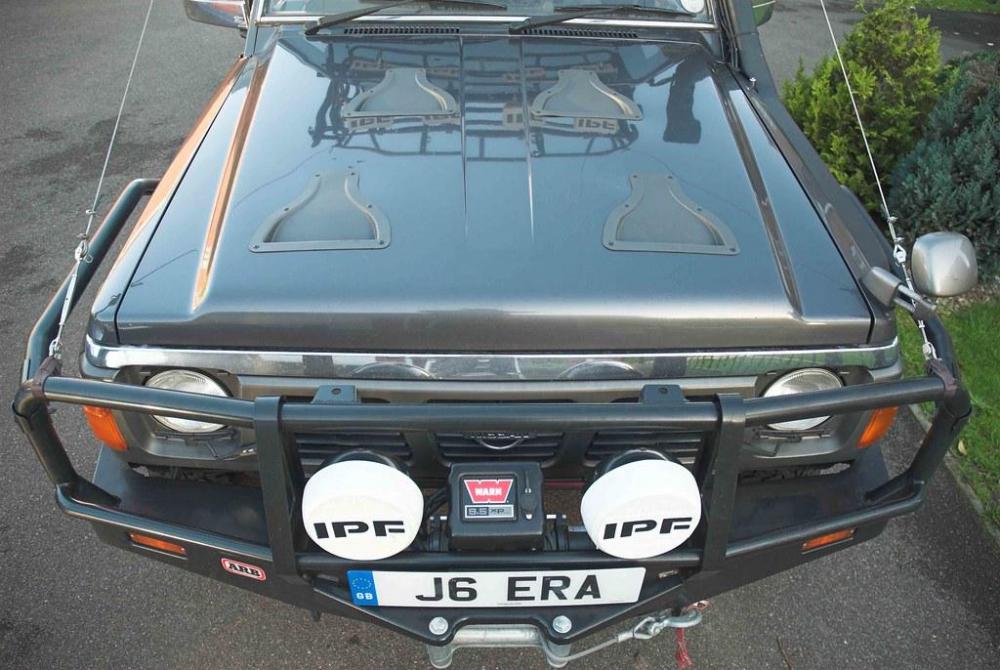

Some good examples of rear facing vents that do not affect tyre contact and removing under bonnet heat and drag but keep bonnet downforce look at the vents in the sill panel bellow the windscreen

Now look at the holes cut in this sill panel center under the windscreen to let out trapped air (drag reduction)

Now look at the holes cut in this sill panel center under the windscreen to let out trapped air (drag reduction)

-

-

Great idea this

-

Agreed loving this.

-

Great idea this.

This also can improve aCeleration and throttle response if setup right.

I removed the wax stat and adjusted the throttle stop screw so the idle was at 800rpm (this is with the idle screw closed) I then adjusted the idle screw to 1krpm.

i run the tps so as to remove the idle state switch and bring in the wot switch sooner. But this is due to my injector size and fuel pressure setting. Saying this removing the idle state switch helps throttle response regardless of fuel setup.

-

Love the build.

i recognise the black gt in the picture I think I met this lad at a jap car festival afew year back. I think we also got smoked by it on the a55 haha. Fast thing if it's the 1 I've seen.

-

On 3/23/2020 at 11:34 AM, ChaseWheatley said:

That’s a lot to take in there buddy...Note to self.. Don’t read your stuff when I’m sleepy 🤣

Yeh sorry chase.

it's all because of what I do. there's a lot of things I forget others will struggle with.

im going to document the starlets development, comfortably predicting step by step the results that will be seen. it's just the level of the results which will determine the clear development path. Speed and fuel efficency.

As soon as the good weather is here I will start to get dyno results up and plot this path with targets on power, efficiency and mph times. Developing every area of the vehicle keeping it as simple as possible with a cap on budget and topend speed, and keep the starlet looking as close to original as I can (sleeper).

Ive recently bourght another starlet and have a 5efe engine I'm thinking about developing for a little track (fun) amateur competionen.

Because of the age of the vehicle there's a lot of documented evidence on two main websites. With a great range of turbo and setup data/info.

The level of engine failure is alarming with all 250+Hp builds.

I've not read a single one yet that didn't seem to have not finished in engine failure. From track cars to competion, strip and fast road. Linking builds on hear with you tube videos.

-

Now this is a quality rod.

-

Yeh it's important to place the oiler hole just off centre to allow best use of oil hydrolic action on this top part of the shell other wise it just forces the oil threw the hole and shell contact will happen make the drill hole as small as possible, boost pressure does this to shells

-

Yeh will do because of the coolant flow paths around 1and 2 and the pump on this end also this area was the lowest pressure point, around cylinders 3&4 were the highest and more stable threw the rpm if you look at the head gasket design and coolant flow control holes you will see why and the pattern to flow improvements in this area the block around 3&4 cylinders is a water trap area. 1 thing he didn't do and wanted to was measure block temp in this area he predicted an increase in temp but never got round to it. he repaired these cars also and has noted a lot of internal and external failures linked to this giving some compelling evidence.

If you picture flow paths from the pump up threw the head gasket control holes threw the head to the thermostate you can see the water trap around 3&4 cylinders this leads to good block pressure in this area, and all kinds of problems for the very poor water pump design.

A lad called Chris from Manchester. I believe he tunned on here for awhile around 2010. Hes moved onto more modern engines now but past all his work on these onto me. Really very in depth engine development. A lot of my info comes from his work.

-

Good lad, well worth it.

A lot better for control and power output than a large manifold and single throttle.

Send me some pics if poss and message me if you need any help or advice I've run afew cars with itb setup.

I know room in the engine bay is limited you might need to upsweep the runners so as to not skimp on the inlet plenum chamber size this is critical for big Hp.

-

I'm going to have to get mine painted I think.

Keep the progress coming looking real nice.

-

-

This unit is off a Audi 4.2ltr with a big low gas flow speed high Hp volume manifold for great full rpm power.

the large single tb and inlet design has the affect of narrowing the engine power band and a skilled driver with good skills and gearing insight to keep the engine in this band needed. Hard work and lap times will differ dramatically.

Any body running this type of manifold cams like the 4efe and these type (twin plate) of throttle setups are required for road use to promote low rpm manifold/head gas speeds. This will also spool the turbo better sooner.

These manifold promote high Hp levels at peak rpm but reduce low rpm gas speed this is the area of fouces using cams and throttle control. The larger the throttle diameter the less sesative it gets and harder for the driver to control low rpm speeds this then affects topend Power targets. It's a balancing act. Another area of fouces then is the available air volume before the throttle a large plenum or power box is needed in this section of inter cooler piping to not choke out the manifold.

You need a very good turbo to extract the available power out of the manifold. a tdo5/6 equivalent that will operate to it potential on the 4e. Anything less like a tdo4 or hyb tdo4 will not work the large manifold type the torque drop off will be in the manifolds power zone making it a wasted effort.

A better design is itb, individual throttle bodie design look up the Nissan sr20 pulsar to see a working example this removes a lot of the headache and control is back with the driver with a added benafit being a near even cylinder power delivery.

-

Looks a good design straight intake runners to plenum chamber, 45deg angled throttle mount gets better air flow to cylinder 4.

What is your power aim I'd use this with a big turbo around 350hp capable and a low rpm peak flow cam setup. A twin plate throttle body would definitely be benafical on this also for low rpm gas speeds/torque.

-

Hello.

Tidy work, what are your plans.

-

On 13 March 2020 at 6:08 PM, RobSR said:

Can you share where the results to this test are and who did it?

I’d be interested to compare this to the data I’ve got off the dyno.

I don’t think taggy’s problem was the water pump..plus he wasn’t high power all things consideredYeh I'll dig them out, the lad that had the starlet I bought did the tests and I believe tuned starlets for like 15 year+ his work is comprehensive and impressive highlighting many areas of improvement on this vehicle. The book he has handed me is like a tuning guild to the starlet. The only things I'm waiting for off him is the dyno graphs he's got, which I need so bad. He's a busy guy. Like us all.

A fast way to show you the heat/cylinder difference is to do a plug read you can clearly see cylinder temp difference is large with cylinder 1 running the hottest threw to 4 getting progressively colder, almost needing 2x different heat range of plugs to be run its that bad. In fact the lad did exactly that. Remember the plugs are a direct way to read or tell what is going on in that perticular cylinder directly.

-

If you know how to speak engine sometimes you can see it shouting problems at you. The 4efe is a very basic production line unit and some of these updated parts I see are poor at best, not removing all and in some cases adding problems. Take for instance forged rods that remove the standard piston oiler drilling and then do not incorporate any thrust face grinds. Gives me the chills just thinking of the oil control. In all honesty around 250hp at 6krpm I'd set its very reasonable limit unless you are blue printing the full engine to race spec, which is a lot of work.

So we remove the little end oil jet drilling, and simple forget its there so hands up ho thinks this engine will have little end piston failure.

So we remove the little end oil jet drilling, and simple forget its there so hands up ho thinks this engine will have little end piston failure.

Below 4efte updated rods a design that works and improves on standard and in all honesty simple and affective improving many areas.

-

Oh sorry there I thought it was yours I've been digging threw loads of builds recently, the stock water pump is a really poor design. I've seen block pressure test were 4x pressure sensors sensors are drilled and fitted to the block 4x corners and in the 2x sides of the head cam belt end and thermostats end and the engine was put threw its paces the sensors were 30psi (2bar) sensors attached to led lights on the dash. The results were shocking with pressure dropping off after around 4krpm with the water pump end the worst. I run a closed back impeller pumper this helps but cylinder 1 still runs the hottest due to flow affecting pressure were the pump delivers water to the block. There are other things that can be done also. The main issue is high speed for long periods cooking the engine internals. There's lots of high Hp melted Pistons on here. Lots and lots. Look at taggeys 5e build. Is just 1 example

-

Welcome and good looking gt you got

-

What are you using for your water pump. Fantastic build this is the first build I've seen deel with the water pump problems affecting block pressures.

-

Nice pics, abit of track action good to see.

Sock's '2ZZ-GE Turbo' Glanza V

in EP91 Glanza Progress Blogs

Posted

Now this engine is capable of greatness.

great build this.