-

Posts

418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by Frankieflowers

-

EP91 original tachometer wiring to megasquirt

Frankieflowers replied to MegstuBMW's topic in Electronics

I have the opposite situation. A Starlet Glanza ep91 4efte engine and ECU in a Corolla Ee110 Hatchback. The Corolla’s cluster is different as it is full electronic ignition. The RPM signal that comes from the Starlet ECU is dirty and the signal jumps. same thing trying to pick a RPM signal from fte ECU to send it to IGN pin on the Corolla’s AC computer. I hope that you can help! -

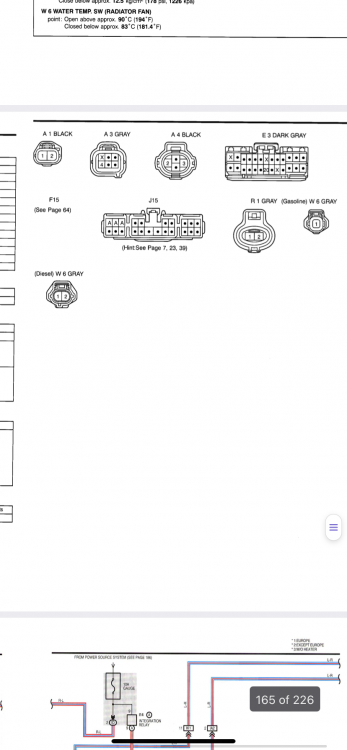

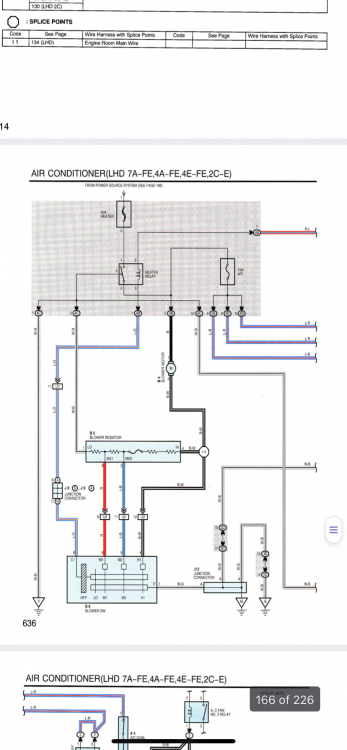

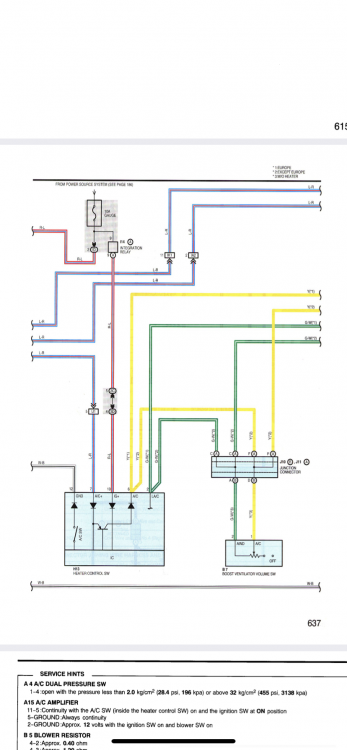

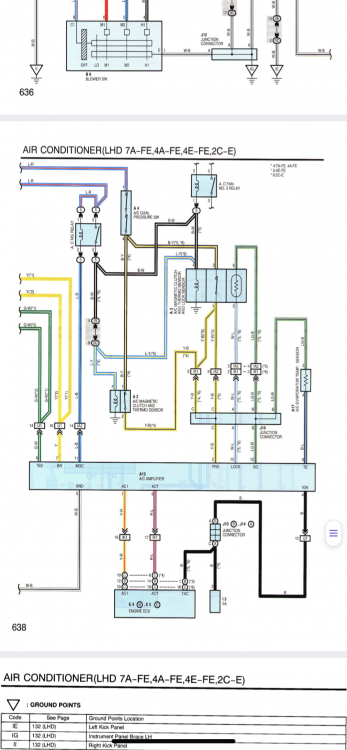

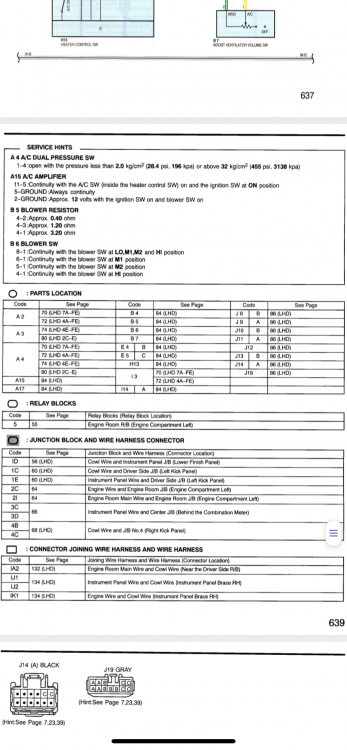

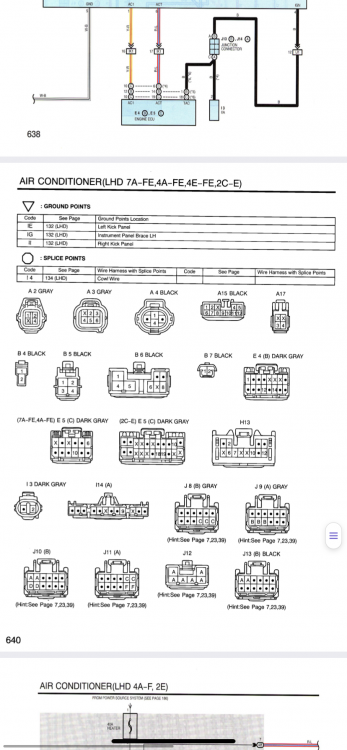

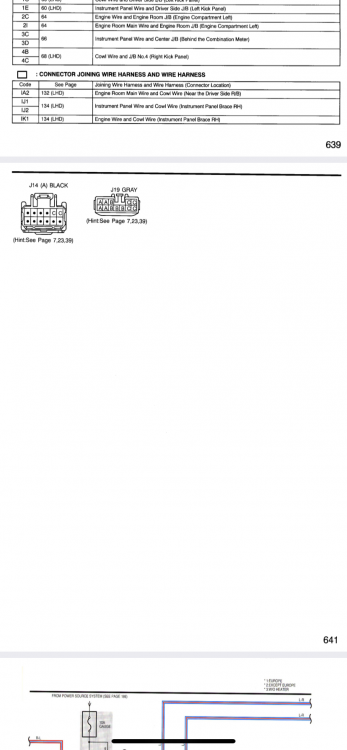

@Claymore The situation is quite interesting. So to recap I have a Starlet for EFTEEP 91 engine with air-conditioning and obviously ECU in a Corolla E11 4efe with electronic and coil ignition. To make the Starlet AC work I need NE and NE- signal that originally was going from the 4efe Corolla ECU from pin 1 to IGN pinout 4 on the AC computer. This signal he’s needed to have the RPM levels in order to permit the computer to switch the air conditioning on and off after engineer condition and to limit it’s work on high rpm. This system on the Starlet works differently because the computer is different. The principle is the same tho. The air conditioning computer needs a RPM signal to regulate its functioning. The easiest way to solve this would be to get the Starlet ecu NE signal but I am not sure if it is possible to split this signal that could possibly create interferences to its original function. We are creating a custom, and adoption that needs to be tested but I want to be sure I don’t fuck up. With someone be able to help me understand if I can use the NE signal or is it another signal I can pick to give the air conditioner and computer and RPM signal?

-

Hey guys. Where does AC2 go from the ECU pinout? I’m adapting the Corolla loom to the fte ECU and the last elements to match are AC2 (that isn’t on the 4efe pinout. The Corolla 4efe ECU has only AC1. Can you help? @Claymore

-

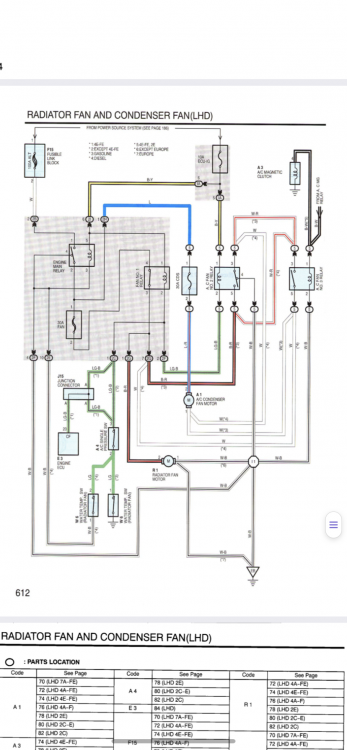

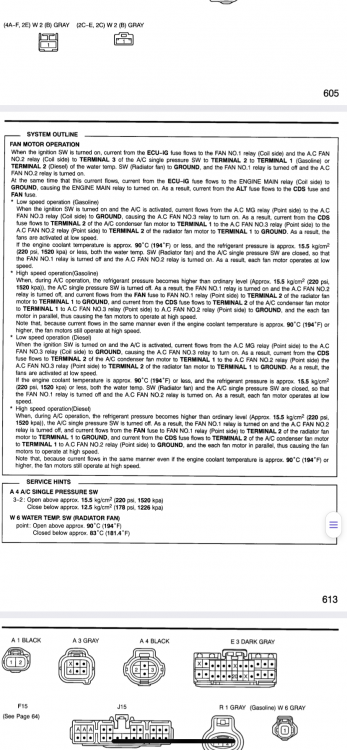

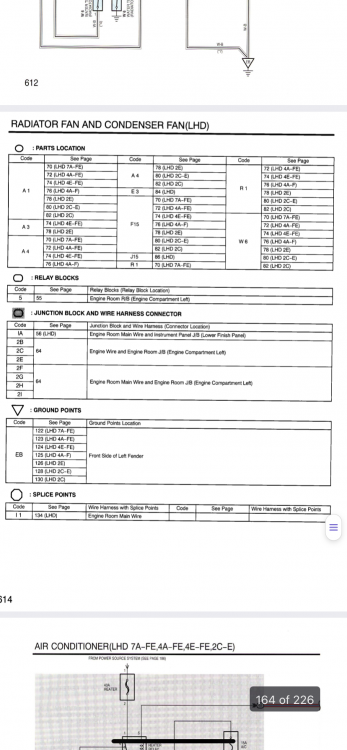

I am trying to figure out how to make the ep91 air conditioning work with the Corolla AC onboard computer. So I have the custom Starlet compressor with the Corolla AC loom that needs to be adapted. Apparently the Corolla COMPRESSOR has five wires compared to the three wires on the Starlet. The extra wires should control the LIMITER RPM CUR. It should also control the second fan. I should choose the correct wires to make the compressor work with the ECU. If I could find a diagram or some help maybe I could make it work my brother help me a little bit to figure out communication from the ep91 ECU to the Corolla AC computer which is the same has the Starlet. What has to be understood is how to connect Starlet compressor to the Corolla air conditioning Loom that goes to the AC computer. Starlet compressor has less wires compared to the Corolla E11 4efe. I need the starlet wiring diagram to compare them. I don’t know where to find it. The only ones I have are for the mechanic part that I already used for the swap.

-

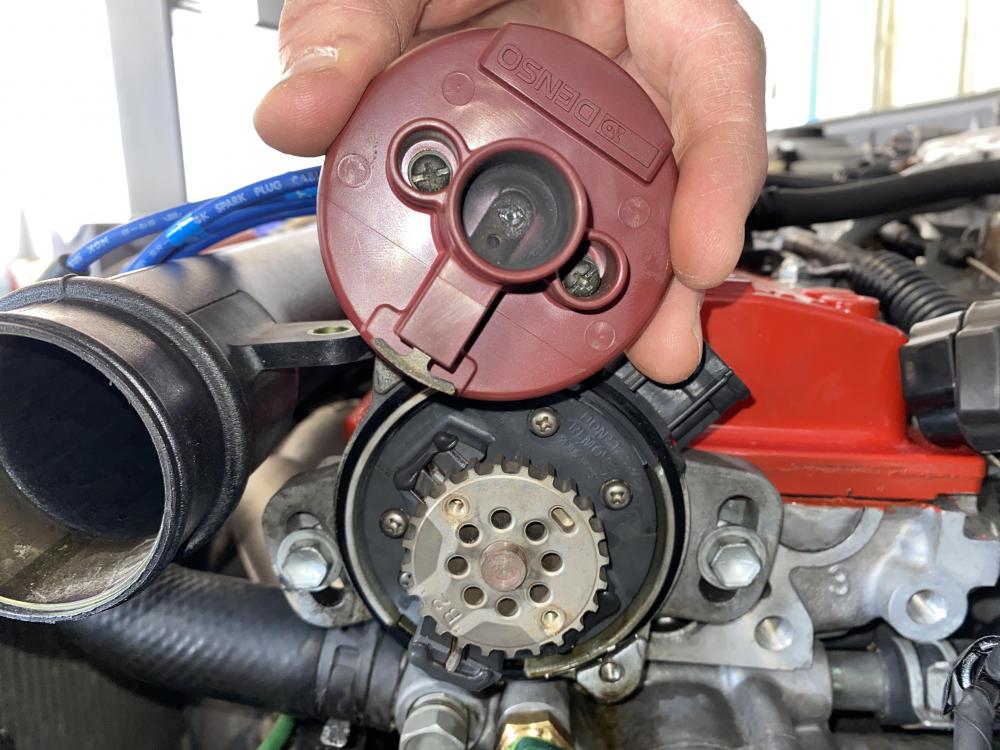

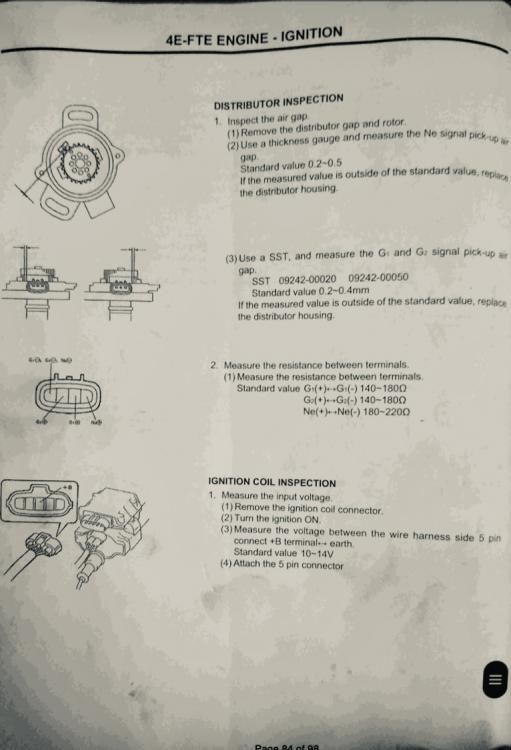

I was so upset that I didn’t take pictures and measures. My partner was helping me out so we put it back together. Let’s say we were hoping it would stop leaking for a bit... I will wait that some of you guys will open a distributor and measure it for me because taking it apart means moving the magnets and needing to reposition them properly. Not a 20 minute job.

-

i opened the distributor to stop the oil leak and discovered the teflon seal inside. It needs to be replaced but there is no information about it and no OEM on the parts website. Why? I changed both gaskets but obviously the oil gets through the dented arm all the way in the rotor box. Please help.

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

@Claymore i’m trying to figure out how to get the Glanza V AC motor work with the Corolla AC computer. The Corolla AC motor has more wire that should control the activation of the main fan as support when external temperature in high. The other function should be the switch off of the motor at high revs. i am trying to make it work adapting the fte motor loom in the Corolla computer. Can you help me? -

IMG_6639.MOV Another thing I still haven’t figure it out is that before we took the cylinder head off for repairmen the BOV setting was perfect. No flutter noise whatsoever. But after we put the engine back together and tested the car I could hear the flutter noise. So I registered the BOV spring pre-compression to fix it but even if I opened it as much as I could it still does the flutter noise. It doesn’t do it fully. It does it for a little bit before the BOV valve opens. I can’t figure out how to solve this.

-

Exactly. What is weird is that when we closed the engine after fixing the head we did the procedure and the timing went from 10 to 0° when taking the bridge off. Of course we never tried this procedure before so I don’t know if it was doing it before but after that experiment it kept going from 10 to 13 or 15°. I thought it was wrong because I read that it shouldn’t go higher when on idle. If you say it is normal I will stop worrying.

-

We managed to refurbish the distributor. It works very well. The only thing that I still don’t understand is why the timing set to 10° doesn’t go to zero when taking the diagnostic bridge off. It goes the other way around 15° instead

-

Today we pulled out the distributor and we opened it to replace the bearing. Unfortunately I did not find any replacement kit on the Internet (besides the 2 gaskets, rotor and cap) and it is impossible to find the internal Teflon oil gasket. I figured it out opening it. The Toyota manual doesn’t show what is inside the mechanism. Your video was helpful but the Starlet distributor is different. The magnets moved so thanks to the manual I’ve managed to distance the magnets and get get back in to nominal measures. I’m glad it worked out. .

-

-

Thank you I managed to get the screws off. I replaced the sensor. at first it was off idle position but then I moved it just enough to work properly without getting idle up %. It works fine. I still haven’t find out why I feel that blowing noise wind the turbo gets on boost and I still feel that the timing isn’t perfect. Tomorrow I will bring the car to my partners shop to replace the distributor rotor and cover. I will try to replace the bearing that I bought with the one side ceiling that should stop oil from leaking in without having to replace the original rubber gasket (that isn’t mentioned anywhere). @Jay if the mechanics work fine after all, if the intercooler system is working fine as before, then what should be making that glowing noise when boost reaches its top pressure? I can’t wait to figure out what happened to the timing and I hope to solve these issues as soon as possible.

-

Hey guys. I received the new distributor cap, rotor, NGK wires and dust cat seal from Japan. I already change the small gasket on the cam when we opened the engine. Although there is still a small leak in the distributor cap. I read around that it might be the bearing or the bearing ceiling gasket. It could be leaking around the shaft. we did take care of putting ceiling paste in the proper position to avoid it but it still leaks. This is why I also bought a new bearing. I haven’t found information about a distributor regeneration on this model. Do you guys have experience of putting one apart and replacing these parts for regeneration? I also received the new TPS. I would like a piece of advice to change it. I understand the procedure about the position and electric check that has been done and I would like to know if the throttle has to be unbolted to do the job. if I am correct, the four pin TPS reads from 0 to 100 with its fader. There is no switch. The three pin TPS works differently but that is not my case.

-

I will disconnect the battery and replace the TPS. I will try the voltage that must be between 3 and 7. I did not find any procedure besides making sure that the sensor is installed properly. I am still looking for a video to see if I can get it off without disassembling the throttle.

-

How do I change the 4 pin RPS on the 4efte? Do I need to reset the ECU after? HOW? @Sam44 @Claymore

-

4efte Corolla E11 2WD to 4WD

Frankieflowers replied to Frankieflowers's topic in 4WD Starlet Knowledge Base

Thank you. If you can help me to confirm parts I can think about buying the car to use the Sasi and make the Corolla 4efte a 4WD! -

4efte Corolla E11 2WD to 4WD

Frankieflowers replied to Frankieflowers's topic in 4WD Starlet Knowledge Base

Thank you. What is your suggestion to get a four-wheel-drive differential on my Corolla? The 1.8 4AFE Corolla SW could be perfect for the swab but someone told me that the differential isn’t bolt on. Also concerning prices I am quite sure that buying the car for 2000 and €600 might be more convenient than finding separate parts to build up the rear transmission and shaft. The fuel tank Hass to be replaced and the best option would be to have a complete car to use for the swap. -

Hi guys. I swapped a 4efe with a 4efte engine in a Corolla E11. I am researching info to convert to 4WD. What’s are the options? I was told that the 4afe Corolla E11 SW 4WD won’t fit the 4efte engine. What do you think?

-

I just spoke to my brother that the other day came by to test the TPS. We ran this test already and we discovered that with the opening of the throttle the tension was jumping in the mid range area and would then go back to lower levels of tension. This is a symptom of consumed graphite. This is why I bought a new one from Japan to see if it will solve the problem.

-

I bought from Japan a new TPS and a new rotator with NGK wires. I also bought a new distributor cap. I read it just in case so I have everything fresh.

-

This is a useful information. Thank you very much Today I set the timing from 7° back to 10° to see how it would react. The engine is running better in mid range and let’s say it’s back to normal behavior. I still have to run the test you suggested because it is obvious that it isn’t acting to its normal specifications.

-

Thank you. Pin one and three are the feeder. The sensor has four pins. It jumps weirdly at a certain point of the throttle opening position that is what makes the acceleration weird between 2000 and 4000 RPM.

-

I am experiencing something weird. I had to take my cylinder head off to get welded because of a small crack and ever since I put it back it didn’t react normal. Everything is set as specifics. First time we tried the timing in the diagnostic mode we put it at 10° and without diagnostic mode it would go down to zero. After we took the cylinder head off again to set shims the timing changed. Set at 10° in diagnostic mode would raise to 15° without the bridge. What could have changed? Thank you.