-

Posts

418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by Frankieflowers

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Can u you please elaborate this? by the way turbo clock cannot be moved. Someone wrote that I could move the hot pipe entrance on the turbo down to be able to reach the rear bolts during disassemble but I doubt that is something you want to do that would compromise turbo clock. Am I wrong or right? -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

The guy at the Toyota shop made me so mad. He didn’t help when O aaked him about the two codes before ordering them. I hate to waste time and money. He won’t take the extra bolts back so ai had to pay for them and won’t be able to do the job in the weekend. On the other hand Toyota could have showed both bolts on the parts website. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

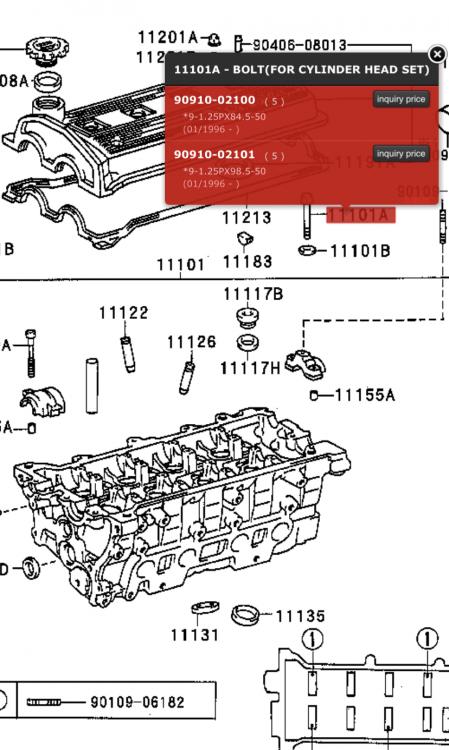

I just went to get the 10 bolts for the cylinder head. Truth is that five are code 100 and other five should be 101. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Of course my friend. We love this engine and I’ve put a lot of passion and money in this project. Nobody will get my dream out of my mind. IMG_5694.MOV IMG_5682.MOV IMG_5663.MP4 -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Interesting post. I agree that engines shouldn’t be opened but unfortunately when things like this happen we have to be wise enough to fix them properly hoping that everything will be fine. I even showed your post to my older brother that has decades of experience and he agrees but he told me that tightening bolts three times should be enough. I am following the procedure on the Japanese manual. I bought new balls from Toyota and I have my new gasket ready. I did not buy new bolts for the camshaft. The cylinder head and valves has been cleaned by professionals. We clean the basement head because we obviously didn’t take out the engine from the car. Let’s wish that everything will be great! -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Which OEM bolts. There are two codes here. Thanks! BOLTA AND WASHERS FOR 4efte ep91 CULINDER HEAD 90910-02100 90910-02101 WASHER FOR CYLINDER HEAD 90201-09024 -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Please give me a link. I checked on the web and shipment form the UK would take at least five weeks what’s the best procedure to take the head off? should I get the inlet off before or after? -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

I have to open the engine. The original manual gives torque numbers. My question is if I use the original bolts and I don’t have new ones and it would take too long to buy them from Japan, do I have to add extra 90° on the cylinder head bolts when installing the head again? once I saw a video where a guy was adding 90° to the torque Toyota was providing and of course following the spiral method. please help. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Can you guys please tell me the procedure to get the cylinder head back on? I don’t have new bolts. I only have the gasket kit to replace some parts. I need to know if I have to go extra 90° when I put the bolts back on. I will once side in a video but I am not sure. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

I know my friend. I am so sad tonight. I knew there was some thing there that was wrong but it was working OK with the temperature up but I needed to fix it. I just don’t want to get the engine apart to bring the cylinder head to the welder. I really wish the guy could fix it with the laser welder without getting the part out of the car. I know it’s practically impossible but I’ll talk to him tomorrow. Where can I find a cylinder head in case this won’t be fixed properly? -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Exactly. It was ticking until temperature was sealing it and it would work normally but I was tired about it so I knew there were something there. I really don’t want to get the cylinder head off. I wish that the welding guy could use the laser system without having to disassemble everything. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

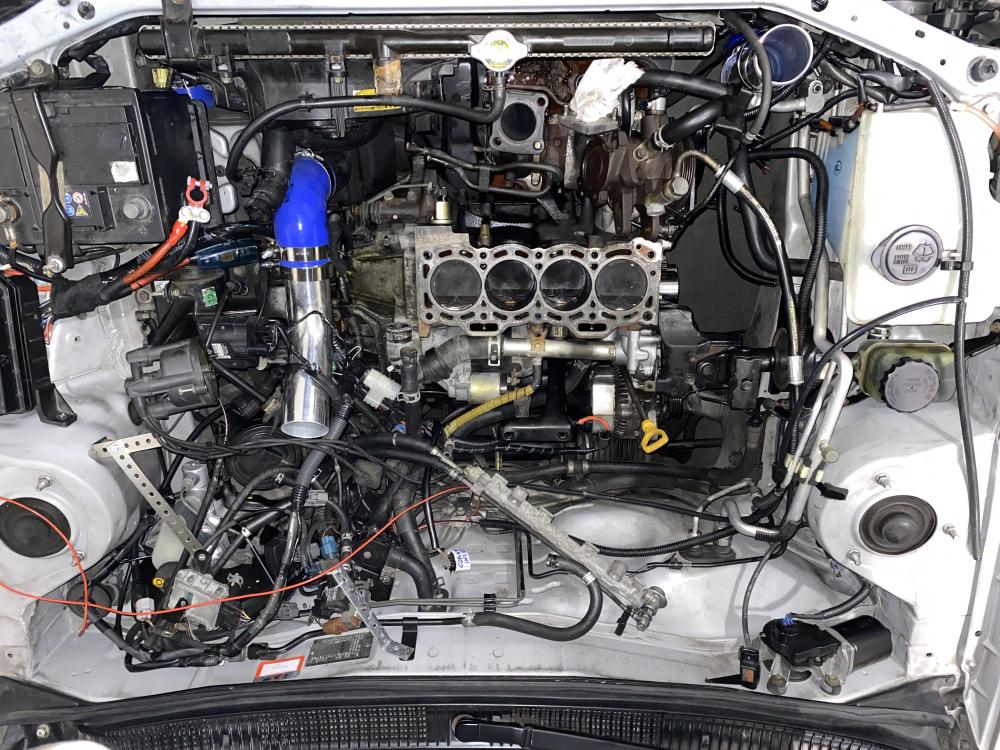

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Bad news. No way to get to the left lower bolt on the exhaust manifold. I had to get the downpipe off and move the turbo down after freaking out to get the left lower and bolt off. It was rusty and impossible to get off. The bad news is that the right and bolt on the manifold went off and showed a crack on the engine. Personally it is external so we might save the situation with some black putty. I really don’t know how you guys get turbo and manifold off. It’s been a nightmare for the last two days. The complication added on top of everything is that the downpipe has been welded on the custom exhaust pipe that is way too close to the chassis and there is no way to get it off. I don’t know how this guy did the job without thinking that I had to take it off one day. Some people shouldn’t work on engines. -

I have the same problem but I really want to try to get it welded without getting the head removed. Is it possible to weld it?

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Bad news. No way to get to the left lower bolt on the exhaust manifold. I had to get the downpipe off and move the turbo down after freaking out to get the left lower and bolt off. It was rusty and impossible to get off. The bad news is that the right end bolt on the manifold showed a crack on the engine. Luckily it is external so we might save the situation with some black putty. I really don’t know how you guys get turbo and manifold off. It’s been a nightmare for the last two days. The complication added on top of everything is that the downpipe has been welded on the custom exhaust pipe that is way too close to the chassis and there is no way to get it off. I don’t know how this guy did the job without thinking that I had to take it off one day. Some people shouldn’t work on engines. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Problem is that the two bolts underneath the manifold are impossible to reach. How can I get there to get the manifold with a turbo attached out? -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

We’re gonna take it off the engine to check if and where the crackers. I already spoke to my welder. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

We’re gonna take it off the engine to check if and where the crackers. I already spoke to my welder. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Last time I checked spark plugs I noticed they were really lean but only on the ring. Could it be the exhaust manifold with a crack? Could it be too much air on Idle? The car seems to run perfect on meat and high rpm. We didn’t try to turn off the engine on high rpm and check the spark plugs. The EXU is custom so I wonder what could be wrong. -

Oil Pressure And Temperature Gauge Installation

Frankieflowers replied to Steve GT's topic in Electronics

Hey thanks for the tip! You mean that by passing the sensor I will have more boost in first and second gear? -

Oil Pressure And Temperature Gauge Installation

Frankieflowers replied to Steve GT's topic in Electronics

Hey Nick. Can you confirm which adaptor isI correct for this application? Which oil temp sensor did you use? https://www.ebay.it/itm/OIL-TEMPERATURE-GAUGE-SUMP-PLUG-ADAPTOR-FOR-1-8NPT-GAUGE-SENDER-/153224536111?mkcid=16&mkevt=1&_trksid=p2349624.m46890.l6249&mkrid=710-127635-2958-0 -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

You know I always followed your advice and here I am with a stock engine. I just want to get rid of that noise and I will inspect the manifold. I do want to fix the gas flow because I read bath it should be fixed to avoid engine issues. I have a shop that can weld it and I will ask them to teim the inside Arrow dynamic limitations. I just want to be sure we trim it properly. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Thank you. I really wanted to get rid of them stock manifold internal flow reduction. Like you did in one of your threads where are you were showing the process of making the air flow better. I would keep the ct9 to stay around 180 hp for a daily use. I’m saving the money to buy the emu classic that my shop will map from scratch. It’s quite a lot of money including the lambda... but first I have to be sure that everything mechanic wise works. can you link the thread where are you modify the stock exhaust? Of course the FTE engine manifold. Thanks -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

I finally figured out that my exhaust manifold is cracked. The ticking I hear on the front engine block that fades away with the raising of the temperature is the cause of the malfunction. As I know that the stock manifold isn’t 100% performing for the life of the engine, I would like to know which aftermarket exhaust manifold I should buy. @Sam44 @Claymore