-

Posts

418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by Frankieflowers

-

@ClaymoreI solved the problem changing the thermostat. The gasket was loose so the cover wasn’t sealing properly. This happened I think because are used a different thermostat that I don’t remember who suggested me was better to keep the engine temperature lower for the reason that the spark plugs were white gray. So I put back the OEM thermostat I had in the box and no more leak! Thank you for your help.

-

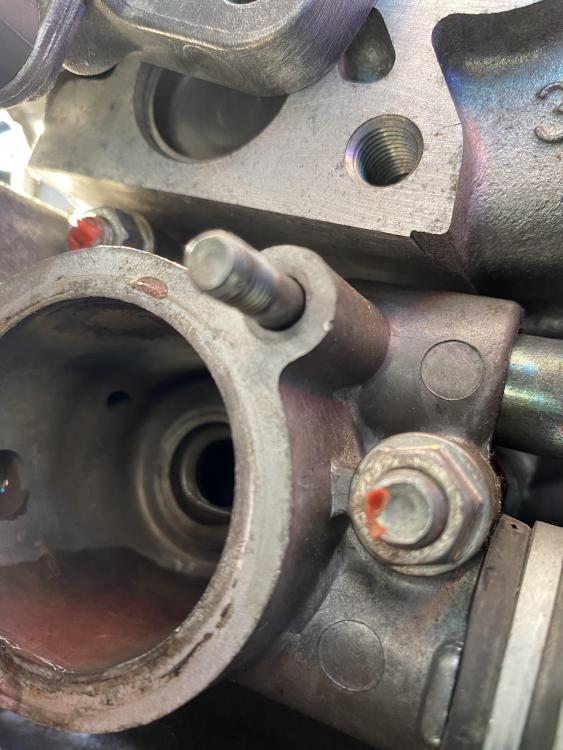

The liquid is getting out from underneath the thermostat cup. I tighten the bolts but after I went for a ride I noticed that it was still leaking. I will have to check again and I really hope it’s not a crack in the engine head. The lower bolt was loose but then I tightened it and it’s still leaking.

-

I agree. I checked the piston heads taking out the spark plugs and nothing seems different as usual. Hi drowned the water system and it was clean without any oil. I put new liquid coolant and leveled it. Went for a drive and after two hours I checked the level that was already down. I drove home and had to put at least 100 ML liquid. There is no area where I see sugar or leak tracks. Consider that external temperature right now is around 34°. The water pump is new because I did everything I could to refresh the engine before the swap. If it happens suddenly it means that something changed. I also checked the oil and it doesn’t seem contaminated. It could be the radiator but it doesn’t seem to show signs of leak or areas of evaporation. The radiator cap seems to be perfect and the spring works well. If the water would be in the oil then the oil would be foam. Right? tomorrow I should be able to go to my mechanic and try the water system pressure to understand more about this leak. I really don’t want to destroy the engine.

-

Thank you for your message. I will check if the Pistons are clean or not. It doesn’t seem that the exhaust color is different and there is white smoke. The idle running up and down around 2000 RPM was weird. I want to look into it better especially because I associate that glowing mid range noise when accelerating in second gear. Very weird. The radiator isn’t new but healthy. I will check today if there is a leak but I can already tell that there is no smell and tracks of sugary elements anywhere I can see. That is why I was thinking about the waterline to the turbo that could be old. Actually if you could tell me which hoses I could use to replace them? yesterday night we had to put tapwater in to get home and the car was perfectly fine. What do you suggest now to avoid minerals ruin the system? Should I empty the system and put water coolant in or should I go with distilled water? my mechanic told me I can go tomorrow to check leaks with the water pressure instrument. I didn’t know about the test to see if there is CO2 in the water coolant. I will check that as well.

-

Hi guys. Something weird happened. A mid pitch tone blowing noise came out in second gear while accelerating. The noise came out after the engine head has been rectified. The most obvious reason could be the inlet not being perfectly tight on the head. Let me know your thoughts. Don’t tell me it could be one of the intercooler hoses because I checked them several times. The second weird thing that could be much worse is that yesterday evening RPM went weirdly up around 2500 going up and down. Right after water temperature started to raise quickly so I turned the engine off. I waited until I could open the radiator and noticed that it was dry. Two weeks ago I checked the water level that never has been an issue on this engine and the previous 4EFE. The water level was OK. I still put some extra liquid because I was about to travel 350 km. I don’t know what happened yesterday but I want to know your opinion. An old turbo water hose leaking? The big hoses are completely fine. I didn’t find any sugar around. The thermostat housing is perfect. New thermostat changed a few months ago. The engine never had any temperature issue. Listen to this. A famous mechanic I know said that when you do the process of rectification on the head level you might be careful to not create a gap that could get fire in and burn the gasket. There is a calculation you can do to see if you are within parameters but nobody does that. I don’t trust the people that did the job and I might be right. The water went somewhere. I never had temperature raising so what could’ve happened?

-

I had several conversations with Sacha from Sri Lanka. this is not out of topic because the mechanical changes I am willing to apply to the engine should be done to make sure that adding power with the DET 3 piggyback will be safe. in my head there are two options. After all my research I thought that modifying the stock exhaust manifold or buying a mild steel stock location manifold would be enough to gain more power using the piggyback without having mechanical problems like boost cream. The second option is buying the steel relocation exhaust manifold that demands certain modifications. The water pipes on the turbo has to be modified. There has to be a new oil pipe added on the turbo. The turbo(cold side) probably must be clocked 90° facing down. The air conditioning pipe Hass to be cut on the aluminum part and redirected externally in order to get space for the air filter turbo input. The EFI will have to go and as I want to keep the air filter on the battery side of the engine high will have to create a pipe that goes underneath the manifold and pops out on the battery side. This considering the fact that the Corolla has more space between the engine and the radiator. I would like to your opinion because if the first option doesn’t create turbo issues it would be much more cheaper. Problem is though that Sacha doesn’t make them anymore and I don’t know where to find a mild steel stock location manifold. This option wouldn’t cost more than $700. The other option would cost me $950 for the manifold and $400 for the waste gate. I would have to spend at least $150 to create a new air filter pipe and a new hot pipe for the turbo. What do you think? Concerning the Piggyback, I didn’t find a base map to start so my brother will help me with the wiring but the precious data for the configuration will have to be somehow improvised because nobody I know have done this work on a 4efte. I still haven’t bought the DET 3 but instead I bought the SPL speed limiter that I still haven’t installed because I want to decide whether I will do the full work and use the speed limiter function on the piggyback.

-

This is my actual concern. So yes I want to upgrade. I found the CT9 kit from SASHA. External waste gate pf course. He told him to clock the turbo to get the hot exit facing down to shorten FMIC input. It would also leave more space to custom an air filter connection to the turbo that would be something like the stock efi. I don’t want an air filter on the belts Side because there is no space with the air conditioning pipe. I want to keep the air filter on the battery side. What do you suggest? I was looking for those plastic kits to build exhaust routes but they cost at least $500. I am not gonna move forward if I don’t solve the air filter issue.

-

Zisco CT9 Ramhorn manifold (mild steel)

Frankieflowers replied to wakeabby14's topic in Starlet Parts For Sale

Is it still for sale? -

Zisco Ram Horn Manifold - Block Brace

Frankieflowers replied to batbo's topic in Intake, Turbo & Exhaust

Did you solve the problem? do you suggest buying that manifold? I was thinking about it but I actually don’t know where to find it. -

When we were in the process of grinding the exhaust manifold we figured that getting rid of material in the areas where the bolts get in would create weak areas that could crack. My friend didn’t feel like doing it. There are these Indian guys who sell a custom exhaust made of cast iron. I would have to buy that one and replace it. about the speed limiter I am curious to know how everyone got rid of it.

-

Thank you. The first question is how can I get rid of the stock speed limiter? Can I install the Piggyback and just get rid of that to start? we already modified the exhaust opening the turbo side ports. It’s similar to what you posted on your thread. Is this enough??

-

Thank you very much. So at first they told me it was better to go with a EMU CLASSIC but aa I wanted to keep AC and RPM cluster working, I dropped the option, esperially because I don’t want to change the stock ct9. My tuner came with the idea of the DET 3 and I agree but The thing is that he doesn’t have experience with that piggyback and he doesn’t know my 4efte engine. He said that 1.2 bar on the ct9 wouldn’t be a problem. What do you think? I want to get rid of the limiter that cuts ignition at 185 km/h. I don’t need much more horsepower because I already have fun with what I have. So yes I could reach 180 HP and be happy. Hi also would want to keep the low boost switch to jump from 0,9 stock to 1.2. what do you think about it?

-

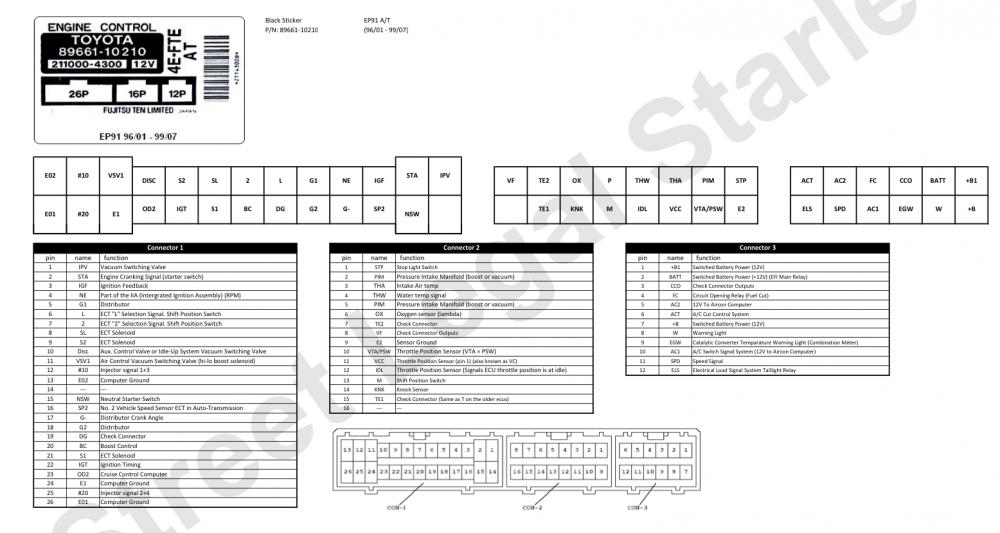

Hi guys. I have to setup a DET 3 on a 4efte engine. Can someone help me with the fte ECU pinoit to the DET 3? @Claymore @Sam44 @RoyalDutchie

-

4efte Corolla E11 2WD to 4WD

Frankieflowers replied to Frankieflowers's topic in 4WD Starlet Knowledge Base

Hi Sam. Dis you ever get a chance to look into the 4efe/4efte transmission compatibility with the Corolla E11 SW 7afe 4WD? -

What 7AFE Bits fit 4EFE?

Frankieflowers replied to The Toffinator's topic in N/A E-Series Engine Discussions

Hi guys. what about the 7afe vs 4efe transmission compatibility? -

Nobody ever replied? I really want to upgrade to this piggyback but there are too many questions and gray zones. That is why I I still hold on to my stock tc9 and ecu. Anyway to get decent horsepower it will need special rods, pistons and a strong gearbox. In my opinion a td04 is only gonna stress the stock mechanics. .

-

I am looking for a distributor housing because mine stopped working. One of the magnets is broken. It happened while I was getting the arm pin out to get to the oil gasket. Anyone can help? Besides finding the big magnet broken, one of the small magnets popped out and I had to put it back in question: how are the magnets poaitioned and why would the distributor stop working after being opened to replace the gasket? @Claymore@Sam44