-

Posts

1487 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by Sam44

-

The info I have on the. Vehicle design a td05 hyb was to big for track with bad power surge and stall but required for good quarter mile times with a tdo6 the best option here due to topend torque output. The Tdo4 hl the best for smooth power delivery and top end torque capabilites for track a rpm limit of 7.5k needed.

-

The final gear on the box is not wear it saves fuel. It gets upto desired speed at 30,40,70mph faster so better acceleration. Reducing loading of the engine (long gears). Also the low rpm engine torque does the same reducing throttle on time (fuel efficient) But you are right a overdrive top gear helps reduce motorway cruz rpm. And these suggested turbos have to sharper torque drop for my cam and high egt and back pressure for the high compression engine. They also require high pressure to run my desired hp targets/power surge. All the nasties really. Also the wheel size difference on the ct9 hyb is crazy I can't see these lasting long. Thanks all the same I ran the tf035 on my colt. Torque drop off was a bitch. In a race you would be winning winning winning oh no wait a min he's coming past. I need a big turbo for this engine cc and a very well designed setup to promote a complete rpm torque curve with the manifolds inlet and exhaust promoting turbo spool and low rpm torque with high gas speeds. And a large turbo to enhance massively the cam/head torque drop off giving a almost table top torque graph that's very efficient. with a great low rpm raise

-

I've been reading about ignition retard. I can't use that method using the na I'm trying to reduce cylinder temps and egt as much as I can, fuel cut for me on a batch firing indirect efi system I would never recomend. asking for det and high combustion temps. exhaust popping antilag will upset the neighbours. So here's the design so far (the pre turbo throttle and fuel stand off valve for the pressure reg I've got out of this book I've acquired) Design and use a electronic controlled pre turbo throttle to help gas velocities/volumes going into the turbo, this will also close out of spool to generate a vacume/negative pressure acting on the compressor wheel removing load and helping overcome anertia lag. This opens progressively to maintain minimum loading and help promote gas speeds. Use a fuel pressure stand off valve like used on the celica and mr2 3sge and 3sgte systems this holds off the fuel pressure raise on the mechanical regulator. This allows the ecu to better more accurately get the fueling for throttle on right because the fuel pressure is stable helping spool time and response. Use a baileys bucket bov valve positioned in the intercooler pipe as close to the throttle body as possible but after the power box installed. The bov valve will remain fully open until the turbo produces positive pressure. Also electricaly controlled. I'll put up before and after graphs of the system and it should be easy to see the bemafits on the td04l/hl hyb. Turbo pressure build very smooth but highly capable of big hp

-

Does any body use or know of any anti lag options. I came across this Turbo and intercooler bypass (D-valve)Edit A method by which a large one-way check valve is inserted just prior to the throttle body, enabling air to bypass the turbo, intercooler, and piping during periods where there is negative air pressure at the throttle body inlet. This results in more air combusting, which means more air driving the turbine side of the turbo. As soon as positive pressure is reached in the intercooler hosing, the valve closes. Sometimes referred to as the Dan Culkin valve. When used in a MAF configuration, the D-valve should draw air through the MAF to maintain proper A/F ratios. This is not necessary in a speed-density configuration. I was thinking about using a electronically control Air valve to close my dump valve as soon as turbo pressure is produced. Im also piping this control valve to the fse fuel reg so as to hold off fuel pressure raise untill boost starts like on the 3sgte system. I've also recently seen alot of fuel parameters on maps altered to run leaner at this point to promote turbo switch on. Which I think engine load and gearing is the dangerous gamble here.

-

I think the power delivered by the masive Td05 20g turbo now on the car is more than anuff to replace any lost topend the cam lost, it's spooling starting from 3krpm on full at 4krpm near anuff in the 4efe peak cam flow rate window. Can you imagine. Edited 4/04/2022, and there's still more to come from this now using this turbo. Here's the ask. Just off the top of your head as I can see your a lad of knowledge. 1) I'm wanting a mitsubishi turbo or garret equivalent for a 4efe 1300cc high compression ratio engine to produce around 190 to 220hp before 5.5k rpm because I'm 40 years of age and don't want to look foolish redlining my car on public roads. 2) I'm also wanting best possible mpg threw experience this requires good engine power and gearing with boost to hit after cruz rpm so around 3.2k rpm 4) money is tight because I have kids so cheapest option here were I can get turbo kits at a premium price. 5) last I need to be able to have a wide range of option on the turbo so as to finally tune it and avoid surges in power and be able to reduce egt. The na inlet cam suits my required rpm power helping kick off the the head gas speeds very low in the rev range. The head is ported for torque also (gas speed) and not peak hp. If I was to go on track I would use the turbo cam and 4efte inlet and throttle.

-

I've never seen a a graph for the turbo I'm running. it's a little bit more than that with a high compression na engine. The profile of the inlet cam combined with the inlet and exhaust manifold gas speeds/volumes. You can really tailor a great engine torque curve starting from very low rpm. This will help spool a biggish turbo giving great mpg and easy to drive speed/power keeping the need to access topend rpm power at a minimum. The exhaust turbine/port does a great job of lowering egt and back pressure holding on that power till the end and allowing higher pressures to be used on the 4efe. I tend to do for feel and dyno graphs over compressor maps. Unless I've got no experience with make model of turbo. Another problem is the power delivery if it hits to fast it will bend a rod. The turbo I'm running at present has very smooth but big power levels making it hard to tell when the turbo is actually turning on. It's both very controllable and reliable which I want for the road. I know with this turbo I'm not going to. Choke it but I do worry about surge

-

Keep them setups and graphs coming please Tdo4 hyb and setups. I'm hoping to order my parts ASAP. What I'm reading the blitz and apexi and 1 of the best systems. What exhaust manifold and waste gate are you running.

-

I think the inlet cam is different on the 4efe better low rpm power flow rates. This is running the 5efe inlet and zisso exhaust manifold extrnaly gated,. All about high low rpm flow rates getting things spooling and pulling. I was told somthing about a Rolla inlet to help low rpm flow even more. What exhaust setup do you have. Many thanks

-

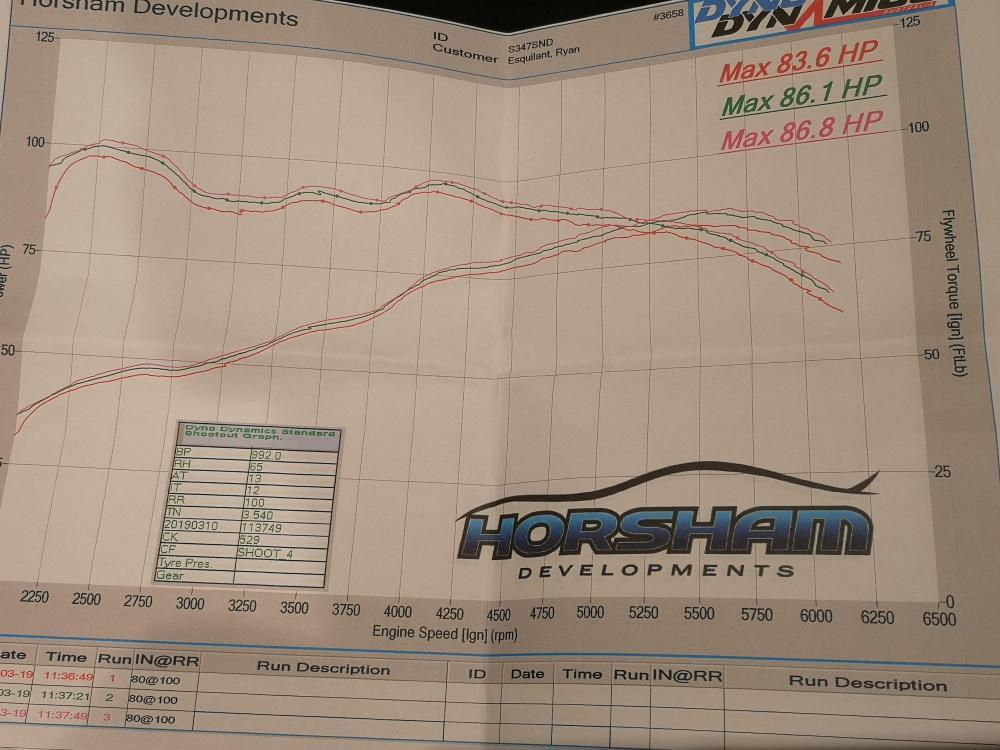

Beauty, thanks alot. Waw great power build there. And holds the torque on till the end. Very nice. The lad that had it only ran as low as a 15t 11 blade billet and swapped it for a 6+6 billet compressor wheel. So he was not sure if I should use a 13t 11blade which switch on fast and surge power but can flatten out near top end or the 7+7 blade which will build power to peak but switch on slow. Can I ask what inlet and exhaust you are running. He also mentioned a roll inlet on a 7+7 blade or somthing. Picture Bellow : 4efe dyno graph borrowed off 1 of the great ep91 builds on here. I've put it here close to this turbo dyno graph above for points of reference on the torque curve mainly (cams, inlet reference). This 4efe has a corrola inlet (rolla), induction cone filter, with standard cams. You can clearly see this is running a different cam setup then on the 4efte engine. The torque drop off is fast and hard. Starting around 4.5krpm and no amount of exhaust or intake flow improvements will help. Making 100hp near impossible to reach making the 93 to 96hp I've seen on some 4efe on here very very impressive. Best option fit 4efte inlet cam then tune the rest. I'm certain if the setup was to see a 4efte inlet cam, and prethrottle body induction power box installed he would make around 100hp and have alot more topend pull torque winning races.

-

Quick question. My turbo is a Tdo4 15t 6+6 blade billet compressor side and tdo4hl 9 blade turbine and port. It's designed for the high compression 4efe engine to run higher boost on track and provide good high rpm torque. As the car is now not track fit and I'm only running it on the road I'm thinking to replace the 15t compressor and wheel for a 13t billet 11 blade to improve low to mid range rpm power. Has anyone run a 11 blade 13t and have a graph. I'm wanting to keep rpm capped at 5.5k and keep turbo surge to a minimum for reliability on the stock 4efe heavy pistons and slim rods.

-

Hello there. Lots of good information in here

-

4e-fe engine bay wiring diagram plus ignition help

Sam44 replied to Mattlmr's topic in N/A E-Series Engine Discussions

I'm also taking taking note of this Rob thanks. And about the ep82 question I don't know I'm very new to this vehicle but learning fast. -

4e-fe engine bay wiring diagram plus ignition help

Sam44 replied to Mattlmr's topic in N/A E-Series Engine Discussions

-

4e-fe engine bay wiring diagram plus ignition help

Sam44 replied to Mattlmr's topic in N/A E-Series Engine Discussions

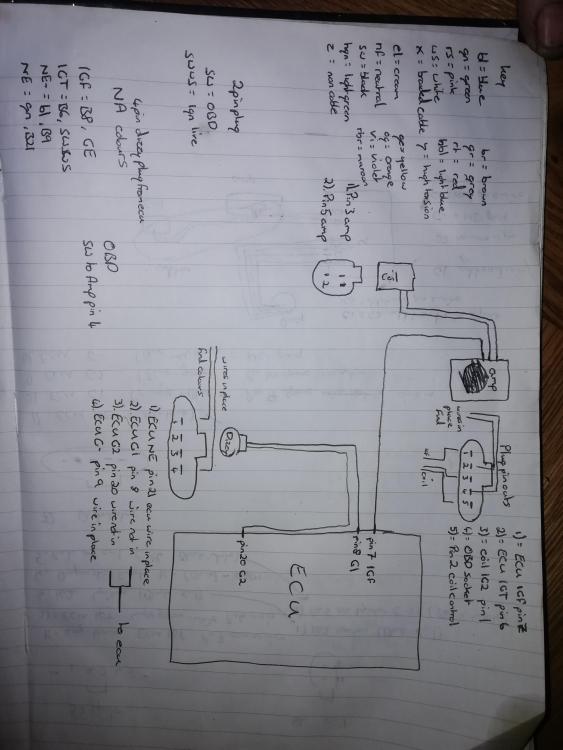

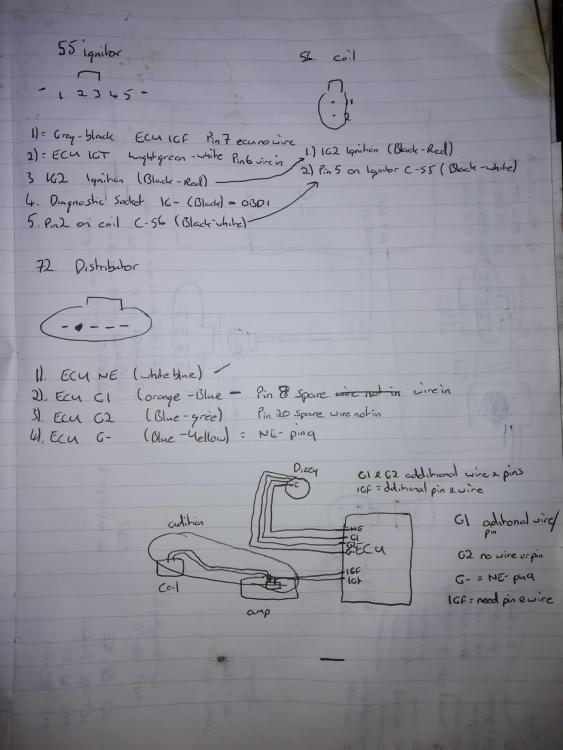

These are some of the wiring diagrams in here. This is a ep82 4efte ecu on a ep91 UK convertion diagram and additional loom needed to fit the external coil and 4efte dizzy. There is so much in this book and all starlet tuning related. It goes on to explain turbo pressure and spark plugs required and after 1bar it's best to run standard tip spark plugs with a higher kv output coil a 50kv c4 coil was fitted here and larger plug gaps. -

4e-fe engine bay wiring diagram plus ignition help

Sam44 replied to Mattlmr's topic in N/A E-Series Engine Discussions

-

4e-fe engine bay wiring diagram plus ignition help

Sam44 replied to Mattlmr's topic in N/A E-Series Engine Discussions

As soon as I'm home I'll put it on. There is all sorts of information in there. -

4e-fe engine bay wiring diagram plus ignition help

Sam44 replied to Mattlmr's topic in N/A E-Series Engine Discussions

I might be able to help here. I've just bought a starlet ep91 UK that was a crazy spec turbo convertion the lad I got it off gave me his build journal and in it there is a wiring diagram to convert a UK ep91 to run on a 4efte jdm ecu. -

Josh's forged 5E Massive spec forged build! 370BHP!!

Sam44 replied to wakeabby14's topic in EP91 Glanza Progress Blogs

There's alot of pride in your work. I've found a 5efe block and crank near me 150quid. Looking at the engines torque levels I can only imagine how it will feel. And from what I'm reading don't suffer from cracked crank main caps like the 4efte/4efe. -

Josh's forged 5E Massive spec forged build! 370BHP!!

Sam44 replied to wakeabby14's topic in EP91 Glanza Progress Blogs

Looks great. I take it you attend alot of the shows and meets. It's very apparent the difference in power levels between the 2 engines. -

Josh's forged 5E Massive spec forged build! 370BHP!!

Sam44 replied to wakeabby14's topic in EP91 Glanza Progress Blogs

I was just reading about this engines stronger and the torque output on the dyno graphs are Really nice. I'm also very interested in this engine. How long have you been building this 1. Such attention to detail. -

Thanks all for the welcome. Not to sure. Its only running low turbo pressure at the minute. I need a few parts I've been told before I can increase it. It's around the 130hp I've been told. But it goes like stink and very good fuel economy. The engine rev range is full of torque very impressed. I'm thinking more power around 180 to 220hp. clean here up lots of handing mods because at present it's all over the place in the corners and get her tidy.

-

Thanks. I'm thinking I'm going to have to clean the starlet up and get her painted first Job. After looking at how tidy all of you lads keep your motors.

-

Very impressed. I've jotted down some of the part mentioned here.

-

Thanks I'm reading as much as I can. It's Crazy what these little things can achieve. Mind is blown.

-

It's standard ecu on a aem piggy back. I've Not long had it. I got it like this alot was taken off. I've got the current spec here incase I needed parts. Quite pleased with her.