-

Posts

1487 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by Sam44

-

Josh's forged 5E Massive spec forged build! 370BHP!!

Sam44 replied to wakeabby14's topic in EP91 Glanza Progress Blogs

What are you using for your water pump. Fantastic build this is the first build I've seen deel with the water pump problems affecting block pressures. -

Nice pics, abit of track action good to see.

-

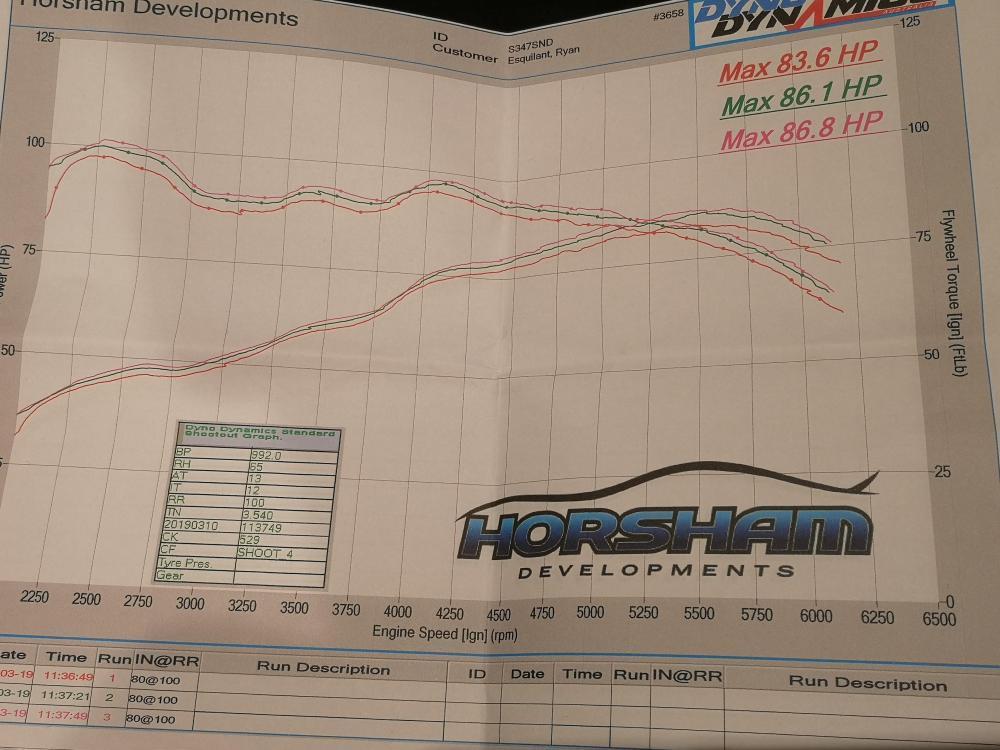

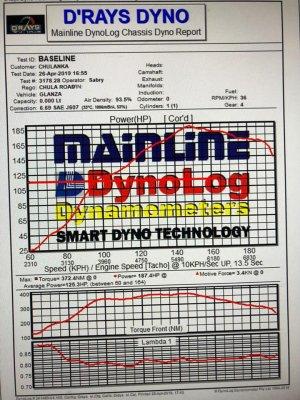

The gen1 4efe gi starlet almost identical as the gen1 in the ae101 4efe corrola here is a engine bay and dyno graph of a starlet gi 91hp. you can see the inlet manifold is identical to the 4efte unit. The exhaust manifold is a 4-2-1 design. The ep91 starlet is 4-1 design. The throttle body on the ae101 gen 1 is tiny to promot low rpm gas volocity with the turbo manifold being so large to promote topend Hp. I believe it is around 30 to 35mm. I'm not sure on the gi starlet but I'd guess at the same size the throttle position sensor is a switch type and not a potentiometer type like on the ep91. You can see the afr hit is around 11.5 to 13.2:1 with the increase/drop in of fuel around 3000rpm to 3600rpm is to much and hurts/flattens off the power curv represented on both Hp graph and torque graph. With the torque not recovering till 4250rpm. this to me is fuel delivery issue to much and my guess would be the fuel pressure regulators increase in fuel pressure. This is the area to smoothen out/slow down the increase of fuel pressure what I mean by that is have the same peak pressure achieved but delay the time taken to reach this by installing a vacuume chamber into the regulators vacuume tube from the manifold. Now around 4000rpm to 5500rpm you can see a big change in afr with Hp and torque recovering and spiking twice this is around were the afr needs to be until around 5500rpm where on the Hp graph you can see a afr of around 12:1 helps it peak again. This is a graph, torque graph is constant with the cams limiting head gas flow rates around 5500rpm I'd say with a small throttle body restricting Hp around 5500rpm, plus the afr to lean from 5700 to 6000rpm where you can see wto conditions are met ( the wide open throttle switch is engaged) if this comes in sooner say 5300rpm things might hit 100hp remembering on the turbo and eariler gen1 engines the throttle wot position is adjustable as well as throttle closed position and idle screw in other words both your low down flow rates and peak fueling is tuneable via the throttle body on the ep91 starlet it's not there's no adjustment to speak of. It's hard to see the peak cam flow rates on this graph with great torque across the rpm range near table top with torque dropping off very smoothly around 5500rpm. Fueling is much better and torque or engine power from the stored energy in the fuel is evident in the results with a slight tweak need to initial fuel pressure raise on the fpr required I'd place a vacuume chamber like the 3sge engine has inline with the fpr control valve to slow down/delay the raise in fuel pressure making it smoother the ems will be able to deal with it and recover better/sooner. This to me is a stand out power/speed tune and the 1 I would go for using the turbo inlet cam the corrola ea101 ecu the turbo throttle body and inlet and basic exhaust 4-2-1 design. With a vacuume chamber in the fpr control line. Ep91 uk na 1.3ltr. ep91 uk starlet graph bellow with standard mods corrola tubular manifold and so on you can see the improvement in low rpm power smoothness and sharp initial Hp raise, the high inlet gas speeds due to the inlet manifold design matches the fuel pressure increase better (also remembering this setup uses a bigger throttle size and a potentiometer sensor for better fueling) but you can still see a drop and recovery at 2750rpm to 4000rpm on the Hp graph seeming slight, but now look at the torque graph at this point now we have a bigger issue, and again it's fueling and more than likely the pressure raise. And ems ability to adjust/recover. This picture below has a lamba graph this is another way of referencing air fuel ratio, with a lamba value of 1 the best afr for cat efficiency. Now ignore the values just at present and focus on the graphs readout the values at the start have a large difference and quickly get closer this is what I was trying to explaine with the voltmeter in previous comments this sign wave form you can see on a analog voltmeter. You can see the length of time it takes the ems to get it under control a very basic system. You can corelate the lamba swings with the torque graph above swings remembering engine torque is related to road speed and engine power efficiency. Hp is the engines adility to rev and things like crank throws and flywheels store energy in a rotating mass helping Hp or engines rev ability. The tell tail graph is the torque graph a near true engine power readout. Now let's look at the final torque drop off this really highlights the cam peak flow rates dropping off around 4250rpm with no recovery and a massive cliff drop at 5500rpm. This is the cam with the manifold finally choking out and limiting gas volume the small inlet plenum being the cause. id sooner have the gi tune and I'd guess there the same cam. The gi will win in a race because it has a better power band and top speed threw torque levels. It was Ryan Lang build and power figures that drew me to this with his tune being very close to the gi. This is tuning in a nut shell with other dyno related errors to watch out for. Remember this fuel setup is a batch firing indirect injection type you will find to correct these fueling problems just using a mappable control unit you will have large value adjustments on the EPROMs look up table. This to a trained eye highlights the basic fuel injection system and the errors in the system it brings. This is a danger zone because these new values are created because of the injection system type and the new values will not meet all real world conditions mainly to speed and engine loads. It's better to tune the setup of the engine and mechanical systems first to suit proformance with low/start rpm areas and peak normally the danger zones with engine load the key factor. When your base tune/setup is as good as you can get it then you will find mapping yield more Hp easier. Little things like fuel pressure and pressure increases, map sensor tube length and diameter, throttle position when fully closed and wot switch, spark plug gaps and cylinder thermal efficiency all affect this and on the gen1 are adjustable barring the fuel pressure peak pressure. Thermal efficiency this is the reason the passeo and other 5e motors run a 78deg thermostat from factory. I've only Been on this engine since October last year and I'm sure a lot more will come to light as I progress the tune of the starlet. A better modified tubular inlet helping the topend torque drop off I believe this is a standard mod in certain parts of the world and widely known about this with the turbo inlet cam would be something to see.

-

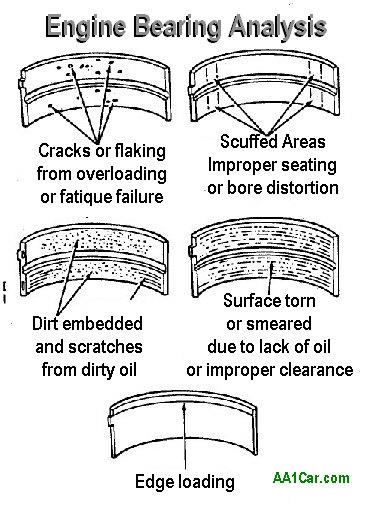

I've just seen this now. Sorry for the late reply with the racing season starting work is mega demanding. I messaged you. You can see the cross brace in the centre This next rod is rifle drilled and because of this employs oil control on the bearing surface also benafiting oil flow rates and thrust face friction/contact, looks closely at the rod to crank thrust face these notches provide this... Image oil being constantly wiped around the trust face areas also helps stability of the crank threw oil pressure reducing crank walk with high load clutch unit. They also face upwards for a reason lubricating the piston and little end jetting. Bellow are other examples and a tapered design reducing trust face surface area benafits shell oil control but reducing oil misting leading to crank case pressure. This is normally used on engine with race clutches using oil pressure to stabilise cushion crank walk/end float and operate at a moderatly high rpm. More examples Now below shows the standard rods design and oil jet drilling in the big end this jet drilling is to lubricate the little end to piston contact surface, note its position central to the big end shell. This causes the flow oil flow to migrate to the centre and causes shell wear contact on the outer 2x edges and thrust face contact frictional losses, parasitic losses these are know as and lead to a reduced engine service life

-

Kev's EP91 Glanza Rep Build - HOW TO DO A 4EFE CLUTCH CHANGE

Sam44 replied to Keviano27's topic in EP91 Progress Blogs

These little cars do look smart in red. looks to polish up well. -

Really enjoying people's builds. Getting skills. I need to get mine painted. Full paint.

-

Yeh I'm surprised very surprised my self the efe inlet cam has been missed for the big turbo mods on the 4efte, and the 4efte cam on the n/a engine. You can clearly see the difference on the dyno graph torque curv. This curv on a n/a engine basically represents head flow rates and volumes as well as fueling against rpm issues. You can feel the engines lack of high rpm torque/speed. With torque drop off from 3krpm to 4.5k alarming with a bad economy related fueling issue or air delivery volumes and fuel delivery mismatch at low rpm in the standard map present also as this is you target power zone for road proformance. at 80mph in 5th gear there's zero engine torque for such a light weight car with good Hp figures. As I dig deeper into this problem I've found the fuel pressure regulator pressures increase on initial throttle is hurting the afr and the ems (engine management system) is struggling to recover the afr. What makes this stand out is the fact the corrola tubular manifold dyno graph with its much higher start gas flow speeds deals with this better delivering more air at this point mixing with the extra fuel. As you will know on such large itbs and the standard ems look up table being so basic the pressure increase will on both na and turbos hurt the low rpm power. The solution is slow down the pressure rise so the ems can at least deal with it. I'm using a vw inline vacuume chamber to delay the pressure increase acting on the fuel pressure regs control valve. With good results so far. Yeh you will struggle to get the most out of them itbs with the standard efe cam configuration it's designed for very low rpm flow rates. I ran side draft delorto 45 carbs on my 1.6ltr cvh fiesta and were to big for good low rpm torque great on track high rpm torque with bigger cams. I'm a fan of your work and aproutch to tunning this is purely advice. If you get me. Keep up the great work.

-

Just a link on what I was trying to explaine eariler. You can see here "the swing" what I was trying to explaine is the more it swings between these values (movement) the better the tune. Using the slightly bigger injectors will on initial throttle drive the afr rich. This can be tuned using the injector delivery pressure to increase or decrease fuel volume injected. Using larger injectors and decreasing fuel delivery pressure at some point will meet the same levels near anuff as the standard setup, the difference will be on initial throttle on and short time fuel trim adjustment time. which is were the Hp gain happens. Fuel in this case petroleum is where the stored chemical energy is. More fuel is nearly always required. I've seen this used first hand many times to great affect along side reading spark plugs. The cat converter is at its most efficient at a afr of 14.7:1 but a proformance ratio looks more like 12.2:1 as you can see more fuel. I would fit the injectors last after all the other mods are completed. Your cylinder air volumes will be altered to a level some kind of fueling mod will be required. Running older standard injectors at higher fuel pressures to increase delivers volumes makes the injector work harder heat up and service life is reduced, but a better fuel atomisation level obtained. Running slightly bigger injectors at lower pressures has the opposite affect. The difference comes on initial throttle on fuel will hit a better afr for power as well as short term fuel trim delivery. 4 to 2.3bar on these injectors is there working range. The lad I got the car off used this method and got very good results on the normally aspirated engine I'll see if I can get a graph off him. He also runs different plug gaps across all the 4cylinders and has achieved a blue colour and even cylinder temps. To achieve this he measured kv and spark duration on a ociliscope. Used a 62deg thermostat a 50kv c4 coil and a closed back impeller water pump. Just as an observation look at the Hp leader board on this site, look at Ryan Lang build his torque hit a big figure, with Hp being around 86hp also I came across another raff I think it was, he hit 92hp but again torque was high, another was James with a red starlet, and lee redz green starlet had all the ae101 corrola gen1 4efe 98hp parts fitted a little word of warning if you use the 4efte throttle body bigger unit, it has a different throttle position sensor use the gen1 corrola ecu its plug and play near anuff I have 1 here you can buy that's been internal modified to run on a starlet. I got this off the lad I bought my starlet from he hit 119hp on his using the corrola ecu and turbo inlet cam, 4efte throttle body, pink 7afe injectors, and fuel pressure reg and many more parts, with his torque graph for a 1.3ltr really impressive. These lads had power in the rpm band were others didn't. Using turbo 4efte parts and fuel pressure regs I think raff had the brown injectors. For the other 4efe setups to hit there torque they had to be around 100hp. This figure is very obvious on the leaderboard.

-

Yeh as said the more features it has the more it will upset you I've found with alarms .saying that. The auto lock above a set speed is a nice option.

-

Morning. yeh sorry about that my job is in engine development. I'm used to writing reports. I write a lot at my work station so I have to be fast. Just trying to help. Ive never done Instagram before I'll have alook.

-

Found some good injector info sites here. I think I might have been wrong about pink denso injector engine code it might be 4afe 1.6ltr. https://www.witchhunter.com/injectordata1.php http://users.erols.com/srweiss/tableifc.htm they all operate around 43 to 45psi, 3bar so this gives you a base fuel pressure setting. The starlet ecu also runs the indirect injectors on a batch firing setup so by no means a complex system. Very close to a carb or single point system.

-

It's the response time not voltage reading its self. You will see the swing on throttle then it will bring it back. If you watch the standard setup first you will get a feel for it. Upto you at the end of the day but it works and has been used for along time. Quick question we are talking about a 4efe normally aspirated engine right. Not a turbo. The gray 295cc units are good for around 200hp. I'll find injector data now from dark green denso units 4efe to pink 7afe units are not in no means a big leap. But bigger anuff to hit a power/proformance air fuel ratio and take it away from economy. Near anuff the same as jetting a carb only move in small increments. If you can get hold of light brown corrola ae101 I think they are 98hp gen 1 4efe unit then these are better I I've seen starlets on here run these and dynoed around 90+Hp. No fueling issues at all. The other option is to use a wide band lamba and gauge but these are very expensive but are a great bit of kit.

-

The adjustable reg will help you setup the injectors. You can do this by eye reading your plugs old school. Its like when we used to jet carbs same principle with bigger injectors. These engines run on the lean fuelling side. The pink 7afe injectors are only slightly bigger thy will allow the engine to run rich on initial throttle on then the ecu will try and pull back the fuelling. With the reg u can get it spot on. To finally tune this put a volt meter on your lamba sensor firstly on the standard system and watch the voltage you can see how fast the voltage swings then recovers this is the ecu getting the fueling right. Your aiming for the same response time the faster you get it the better the tune trust me. Then read your plugs you want a tea bag brown colour to blue if you manage a blue your perfect. This will be felt in the pulling power of the motor. The eariler corrola 4efe ecu is easier to tune as it only has a 3 stage throttle switch position, idle,throttle on, and full throttle but the later starlet has a potentiometer on the throttle position and faster ecu. Or some people get good results from replacing the air temp sensor with a veriable resistor and adjust fueling with this but mpg will suffer. Message me if you need help. For the earthing kit you want at least a 12mm cable from the battery to the alloy head, this will help the spark and igniter earth properly also 1 12mm cable from the battery to the engine earth bank at the back of the inlet manifold, this sharpens up your sensor signals helping ecu response times. Finally if you use a fse regulator these have a large pressure increase of around 1bar standard regs are around 5 to 10 psi. The drop in or increase in pressure is very sharp on the fse so if you place a vac chamber like found on the 3sge engine "t" into the regs vacuume pipe the fuel pressure rise becomes a lot smoother and slower allowing the ecu to respond better but still keeping the fueling on the rich side. Again this can be seen on the voltmeter. Trust the voltmeter and only adjust the fuel reg in very small increments like 1psi at a time. You will get a feel for the best tune/voltage response after a short time of driving you want a fast response for good mpg but not to fast as this means you are close to standard fueling. You will feel the best tune and see it on your plugs.

-

Let us know a price on all them parts if poss. Looking good. Its crank to rod ratio and piston crown weight that counts on rpm. The rod can be utilised at this point to work on a slipper piston design and all the benefits A really good piston design could bring to this engine especially. Reading threw the big Hp builds on here nearly all fail around 300hp, with 250hp seeming to be the point at which they can last. With cylinder temps being the main killer from what I can see. Im running a better water pump with a closed back impeller. The engine suffers with bad cavitation dropping block pressure around 4krpm upwards slowly getting worse. With cylinder 1 running the hottest threw to 4. The water pump position with the coolant flow speeds just behind cyl 1 being high leads to low pressure points around this area. There's also the power balance issues with the ht lead length difference, the uneven turbo manifold air delivery. Fuel rail devilry problems. A lot of issues to sort before rpm can really be pushed. But im definitely interested and I recon I could do a great piston design to contribute. A good windage tray and piston oiler jets would also be a big big help. Reducing sump pressures and piston crown temp dramatically. The oiler ports incorporated into the standard rod big end are poor and oil splash/feed issues to the little end will be a problem with increased rpm. A rifle drilled rod the answer supplying the little end with good oil supply. A better oil pump rotor design would also help oil supply. The nissans use a 5 point oil pump rotor were as the Toyota 4e uses a 3 point. The oil filter also has a very small volume of filtered oil. All in all you can see straight away this is a very basic production line motor. To be able to push the 4e in any kinda direction will be an effort. Increasing rpm being 1 of the most challenging. 1 of the areas the engine production line model stands out in is its strength working with in its limits is the best cost affective rout with a lot of off the shelf items available. Areas like topend speed, power levels and engine rpm the fouces points and dream killers. I've been knee deep in research on the 4e power unit since Christmas and for Toyota/Yamaha to make a 8v head into a16v head very cheaply and it work this well I can only describe as jap magic. This leads to some crazy head flow issues. message me prices please.

-

So shorter stroke would suit more. You can go either way. Im reducing rpm limit to increase the engines service life. On the street car at present. Im just at the point of testing cam lift on piston clearance and power levels, To work out the rod length required. From what I read there's 3 different cam configuration on the factory e series engine 4efte,4efe,5ehfe. I have them all here. With me running a mid to large size turbo to amplify the higher rpm power drop off of the lowest factory 4efe cams (lowest lift) that really give great low rpm torque and head gas speeds also aiding turbo spool. I just need dyno graphs to see which way to go with the cams/turbo design. But yeh the masses will like these light weight strong rods.

-

I was reading polo 6n2 fit with slight hub bolt mods and removing top mount spacers or something 5e Colin on here did a how to.

-

Also check your fuses there's a efi fuse under the bonnet

-

Love it what size are the itb. The 4efte also has a higher lift inlet cam for better topend Hp it doesn't seem to be common knowledge.

-

Sounds like you have either a fuel pump issue or ground wires off. Check your earth banks both on the engine and chassis and to the battery. Then do a blink code read out see what fault codes you have.

-

Are they standard 4e stroke length/compresstion ratio. Im looking for some with a longer length to increase compression ratio so I can loose some crown weight and heat. With the cam setup and valve formation leading to a wedge shape combustion chamber I was going to design a slipper piston to improve gas movement/mixing. Staying standard stroke/rod or smaller length gives you room to reduce compression ratio and at the same time reshape the piston crown. cylinder mixing and scaverging on the 4e is poor leading to poor cylinder squish and stall gasses at low rpm. I've seen a lot of head gasket issues to many. Very thick head gaskets also do not help the issue. To improve/increase compression ratio will improve low rpm engine power output and improve engine efficiency but will lower boost pressure limit on standard pump fuel, (better for road proformance or small tracks) to lower stroke length gives room for a better piston design no loss of crown thickness or ring land strength and reduces compression ratio for increased boost levels big Hp for track only application really. I've been working with our cad department to design a piston just at present but I have to much crown weight for my target compression ratio. A increase in rod length would would allow me to reduce crown weight and keep my compresstion ratio. I'm going to run duel fuel, lpg along side of pump fuel together. Really increasing octane and very cost efficient. With lpg the cheapest fuel around. At work we are getting good torque outputs from running lean fuel mixes with lpg it's very stable and powerful. The new generation of trucks is set to also follow this rout with big mpg saving. The 5e 1.5ltr engine has the ideal crank to rod ratio for good torque output and stronger crank main caps. The 5e also imploys the longer rod higher compression ratio lower crown weight design, out of factory. Just to give you some advice and research so far. The figures so far suggest that compression ratio on the 5e could be dramatically improved in a number of areas head material removed and gasket thickness. This will allow rod length to be ruduced yielding Hp. Just what the 5e lacks at no cost to engine cc or 5e torque levels. With rod and piston design maximising power efficiency and reducing the risk of component failure. With piston crown oiler Jets the next natural mod. I'm playing with the idea of blue printing a very efficient track engine and car for small competion to show case good budget proformance. As well as have some fun in my down time. My road design is to use the Hp giving 4e and extract as much torque as possible, efficiently from the engine keeping the 4efe standard internals and lower or should I say very smooth boost/power delivery. My aim is 5e Hp to torque output levels. This also employs the duel fuel aproutch with 40mpg + @250hp the target. Designed for road daily proformance. This is today's performance car design targets. I hope you realise why I'm telling you this as rod and piston design and production is not cheap. And I'm equally disopointed with the so called unrated products available for these engines.

-

A lot of good options out the toads are also very good but complex to install yourself

-

Hi there. For instant proformance on the 4efe 1.3ltr I'd replace the exhaust system for a 2inch diameter straight threw system. Replace the inlet cam for the 4efte Unit. Use a 62 deg thermostat. Also use the Corolla inlet (tubular inlet). Use a good adjustable fuel pressure regulator, and 7afe injectors You should see around 95hp. Platinum plugs and a earthing kit also helps the low kv coil. Or you can use the turbo inlet manifold and the 4efe inlet cam with all the others mods suggested and see around the same power but no more room for improvement. The light weight flywheel and 6speed gearbox is another instant gain.

-

Real nice work

-

Now we are talking. What's the estimated cost. Are you pushing rpm. Whats the desired compression ratio and finally are you designing a piston as well.