-

Posts

1487 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by Sam44

-

I'm Very interested, get a build thread wrote up, and welcome to this starlet community. Some very knowledgeable people on this site.

-

I've not got instergram sorry. I'm restricted with my employer as to what social media platforms I can use. Message me your spec list and any graphs you have please, I've found the ep91 build very impressed. Are you keeping the ep91.

-

LHD 6P2 GLANZA from France - 4E-FTE IS COMING!

Sam44 replied to EP70-PT's topic in EP91 Progress Blogs

Credit were credit is due looking great. What size was the itb and did you get any Dyno graphs. I'm after converting my clocks to a glanza v set if you could help me it would be much appreciated. And the projector headlights I'm very interested in. Sorry about all the questions I'm very new to this car. -

I'm all over this, do you have a previous build thread on the ep91, and I was wondering about its spec\build thread?. Following this.

-

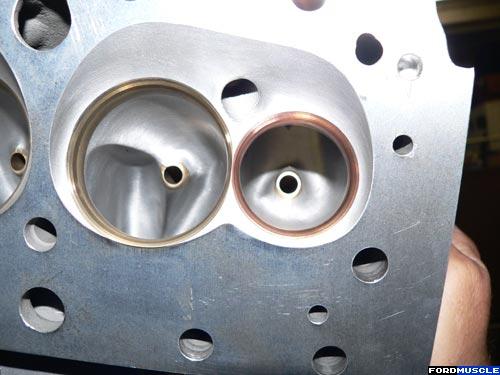

Intake port design producing swirl and tumble turbulence. The blackening in the port is a similar substance to liquid steal apoxy. Which as well as improved cylinder squish and flame propergation these engines desperately need

-

Yeh that's not for 1 of these I was thinking it would be around £8000 Thanks alot.

-

Thanks for the reply, and spec list keep us updated if possible i can't find many tfo35 4e graphs.

-

Thanks, I'll do that could you message me the a guide price. Just to give me an idea. And Waw a 5ehfe as well. I just noticed your location haha.

-

Following this, i know of a lad on the colt owners site I'm on that ran a tf035 he used a tdo4 13t compressor housing and wheel on a tf035 exhaust housing and a tdo4l 11blade exhaust turbine. The thing was 1 hell of a turbo no lad and made power till redline. He ran a large external gate also. Do any of you lads have any graphs with setups please.

-

Still not working for me.

-

It does look so clean. I'm very tempted to get a fresh import GT mk2 quadlight.

-

I'll have 2 please when there ready. Ep91. A really good setup gt Brad. Can't wait to see the Dyno graph it's going to impress.

-

I do need a spare 4efe to measure up for pistons. I was looking at figures from the acis manifolds on the 3sgte and 3sge. With the 3sge engine and manifold out proforming the K20 vetec honda. so you could be onto somthing. Remembering the 3sge and different 3sgte manifolds are a different design to the 5efhe. So this gives room for ideas designes. My only worry is the turbo design and cam arangement on my setup. Against the high lift and duration cams on the 5ehfe leading to the adaptive acis intake manifold design. Looking at Dyno graphs on these setups on the 4e and 5e the manifold changes over runners (long narrow to short fat) around 5krpm. Ramping up low rpm intake gas speeds (velocity) to access the cams 5k+rpm peak flow rates\power/torque. The problem here with the cam arrangements and turbo design I have. Cams are the lowest rpm peak flow rate cam setup on the 4efe with peak flow around 4krpm. Giving good off the line power (low rpm torque) This allows me to drop the peak rpm red line by 1krpm so 6000rpm limit. The turbo tdo4 13t billet hyb design is to operate at normal 3.5krpm to 5krpm range with a slower smoother surge of boost in this range (spool up) for control and engine reliability. delivering better air volumes in this range giving greater torque (3.5krpm to 6krpm) than a standard tdo4. for the desired target of the hyb turbo operational range to be met the intake & exhaust manifold design and cam arrangment are critical. The turbo also reduces mid to peak rpm egt levels for reliability and power gains. The 5efe paseo intake manifold I'm currently running gives great power (flow rates) from base to peak rpm but the power balancing of the engine is off with cylinder 1 being the weakest down nearly 20% at 6psi boost levels against cylinder 3 at the 100% reference strongest cylinder). The intake and exhaust manifold design on these almost controls the power balance offset the other factor is cylinder temp. I'm also massively impressed with the rolla inlets base to 2.5k rpm power levels/flow rates and equally alarmed by its 4.5krpm power drop because of its very small plenium design. The even length exhaust manifold like the zisco (narrow diameter even length runners) giving better low to mid range rpm gas speeds. the bigger diameter exhaust manifold designes aiming at peak rpm volumes not really contributing to gas speed at lower rpm levels. The acis in standard 5ehfe design requiring the 5ehfe cams would more suit a good mid range turbo like the ct9b hyb or a gt17 to 20 turbo or tdo35. Really ramping up the mid to peak rpm power levels to tdo4l levels with much better low rpm spool up, giving a almost complete rpm power range. If the owner now runs a better transmission gear set this design on the road would be near unbeatable by my calculation under 5sec to 60mph achievable and equally impressive 0 to 100mph times.I would strongly recommend the largest diameter external waste gate to be used as well as a 68deg thermo state with egt and cylinder temp cylinder 1&2 needing to be the very real fouces here or else the starlet will be just another engine dead statistic on here. Like most of the high boost ct9 & ct9 hyb mapped cars and certianly track cars I've read about. The garret gtx17 on the zisco designed exhaust manifold and acis cam and manifold would be insanely fast on the C63 gearbox. This setup would also give great road speed level control, as well as very good reliability on both engine and gearbox. The only real room for improvement here would be engine efficiency mpg. If a larger turbo wanted for track then play with the exhaust manifold diameter to achieve good spool up results also accessing good road speeds. Im also of the opinion this set up would hit these speeds with around 200 to 220hp allowing a standard 4efte engine to be used but I would recommend forged pistons and ACL high load bigend bearings. As well as a oil cooler. The design I'm running follows this design but aims at reducing all the nasty temp and power balance issues allowing the high compression ratio more efficient (better mpg) 4efe engine to be used. The higher compression ratio heavier piston crown in the 4efe is why it runs weaker valve springs to cap peak rpm it also has a noticeable lowwer redline limit. Not requiring forged internal or oil coolers and a better in car heat 78deg thermostat to be run for winter defrosting needs. Target hp 240 with equal or more torque. With the buget of the build set at £8k max.

-

WANTED : COROLLA TUBULAR INLET MANIFOLD. £100 WAITING.

-

Hello spray brake cleaner around the outside of the intake and inlet manifold to see if it affects rpm to find a leak. Have the engine running. Also do a blink code dtc read out on the ems to help pin point the fault.

-

Yeh. The body roll on these and suspention deflection is truly shocking in standard form. When I first experienced driving one of these on track to be truthful I did 2 laps and came off in disgust, parked it up it was so so bad. Body roll and pitch, suspention deflection that made the wheels/axles feel not attached to the vehicle, brake bias making in corner brake control impossible and weight transfer\shift\pitch a real problem. Lift off over steering. And a steering rack that felt very unresponsive and lacked feed back (feel). We really changed all this dramatically with out areo work and with some very precise mods. The thing holds the road and gives great feedback. Handling mods are a very beneficial mod on the ep91 and 82 the complete opposite to the ae101 which surprised me.

-

High quality. Agreed a 1.5 on a c60 gearbox would be very capable. Alot more acceleration and torque. Following this 1 keep it up.

-

Its bad this lockdown, so much could be getting done. Alot of mechanical skill on these cars\site. Lovely glanza v keep them updates coming.

-

I'm keeping an eye on this.

-

I hope every one is well. I've been moved onto a project I can work from home and help on. I was last on this three years ago so reading heavy to get me upto speed. So I'm back in sunny Fleetwood. Stressed out.

-

Looks really well. The red starlet's are rare. There is not many on here.

-

Wax stat and idle control valve delete

Sam44 replied to starlet1991's topic in 4E-FTE Engine Discussions

Yeh the big 1 is air con and can be capped off if Aircon removed and the other is fuel tank vent charcoal filter pipe. In order to remove this and blank you need to remove the charcoal canister and vent the fuel tank to atmosphere. I use a motorbike vent valve on mine and make sure the vent pipe is above the wheel hight incase you go threw a puddle. A quick way to know if your charcoal canister is blocked/difective is if your fuel tank sucks air in when you refuel. This is negative pressure produced when the fuel tank vent is fooooked not allowing air to replace the used fuel. This negative pressure draws fuel back to the tank that's trying to head towards the engine. This mod with an engine earthing kit and cleaned out map sensor with a shortened narrower pipe attached (silicon piping) ,gives great throttle response and boost build. -

Wax stat and idle control valve delete

Sam44 replied to starlet1991's topic in 4E-FTE Engine Discussions

Yep and yep but not on the UK 4efe ep91. Only on the turboed 4efte ep82 and ep91. The way I did it was to remove the wax state and clean out the throttle body of any oil and muck. I then used fiber fill to fill any port opening in the Venturi pre and post throttle flap apart from the idle screw bypass port ( basically the big ports on the lowwer floor of the Venturi throttle port) you can tell these ports as they will join the waxstat pre and post throttle flap. This will help remove any turbulent air. You then smoothen down the fiber fill and Venturi port with a drimmel using a yellow stone and then a barrel sander till smooth. WARNING DO NOT DRIMMEL THE THROTTLE FLAP AREA WERE THE THROTTLE FLAP SEATS. now screw the idle screw located on the top outer side of the tb under a rubber cap fully in. (Make sure this is cleaned out prior to setup for best results. Now remove and blank off the idle control valve and all these pipes in the picture. Or you can unplug the idle valve air pipe to this pipe in the picture and bung it with a bolt. Now remove the tps plastic cover (you can see the 2way switch inside) and undo the screws on the tps top and bottom ready to adjust. Start the engine and adjust the throttle arm stop screw small Allen key and locking nut till your idling at 800rpm. Now tighten the locking nut. Set the tps so the bottom and middle switch contacts literally just touch, this is idle mode on the ems. Now thighten the tps screws. Now unscrew the idle screw on the top edge of the throttle body till 1000rpm or 900/950 is met. I set mine at 1000rpm for good oil pressure.