-

Posts

418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by Frankieflowers

-

I checked the voltage output of the TPS. It jumps out of scale when opening the throttle slowly. This should mean that it doesn’t work smoothly.I tried to find a new one but I cannot find it. Could you help?The new reference n. Of Denso 198500-3011 is Toyota 89452-22090

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

I’m unable to open the file in italy. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

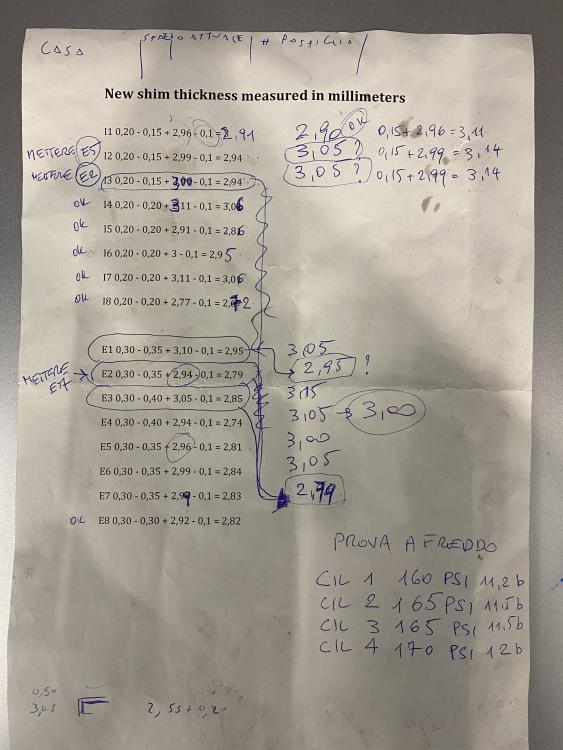

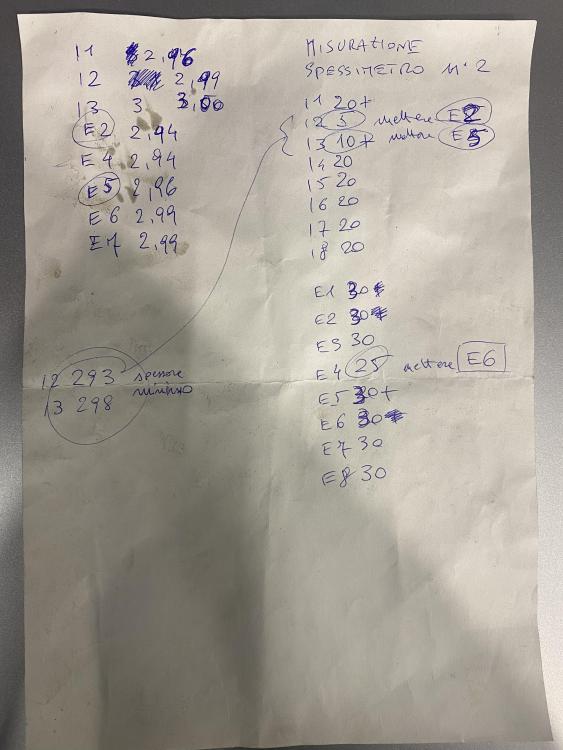

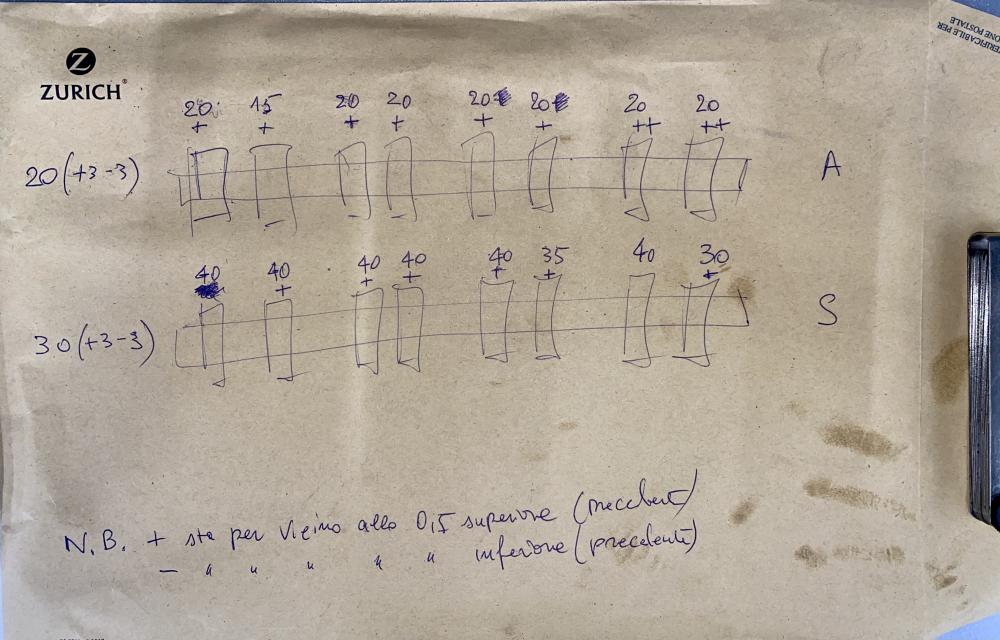

Thank you for sharing. We had to switch a few shims that were out of parameters. Engine seems to be running OK now. The problem now is that the timing procedure is reacting upside down. Setting +10 on diagnostic mode isn’t going to zero when unplugging diagnostics. I really don’t know why the electronics are acting like that but it definitely isn’t a mechanical issue because we did everything right. We already pulled down the camshaft 3 Times ever since I had to send out the cylinder head for welding. The distributor is very simple to fit and we haven’t touched anything that could compromise it’ from functioning properly. Setting timing to +10 on diagnostics brings it up to +15 when unplugging diagnostics. what is happening? IMG_6096.MOV -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

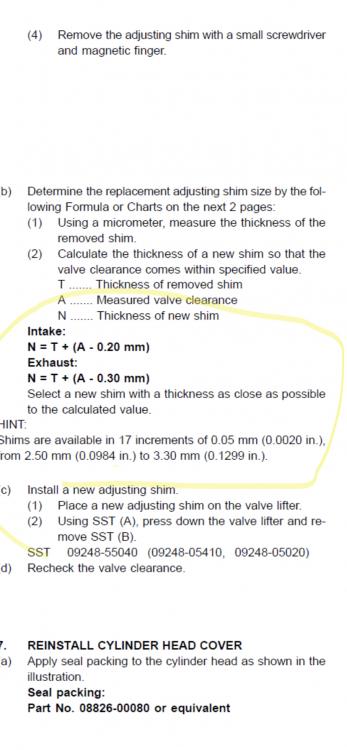

Update. here are the valve clearance measures we took with the engine that was almost called. Let’s say 25°C. before we did this I went to see the workshop that will change my echo and map the engine whenever it will be working fine and he ran a compression test when the engine was fairly warm The result was 140, 140, 150, 150 when I bought the engine from England, the seller sent me a video of the compression test that was 175, 170, 160, 165. As the engine temperature matters when it comes to compression test, I cannot be 100% sure of what has been done by the seller and I can only be certain of what I am doing this is sad, checking the valve clearance we have the certainty that the shims are thin enough to let the valves seal. If decompression is down is probably because the rectification work shop did the job wrong and the valves don’t seal properly anymore this is a consideration that my brother gave me and I agree. He also said that maybe the valves will adapt and the compression rate will raise again but who can be sure about that at first I thought that checking the valve clearance would give me a larger value beyond the limit that would mean that the valves don’t seal properly and a shim rectification would have been done it seems that my hopes or a let down. The question to all. If the formula underneath is correct then how come the engine should have a compression rate psi between 160 and 170? Technically the result is wrong because with an 8.2 compression rate for the 4EFTE engine we are talking about 120 psi can someone explain this? Thank you 8.2 x 14.696 / 1 = 120 PSI 9.6 x 14.696 / 1 0 = 140 PSI -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

We did the cylinder compression test and it went down to 140 psi on the first two cylinders and 150 psi to the other two cylinders. It is obvious that there is a leak and apparently it is not the valve clearance instead it is the rectification done wrong. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

I spoke to the Toyota chief mechanic and he told me that they usually measure the valve clearance and then the use the table with all the specifics to calculate the right shim thickness. They send the measures to a workshop to customize them. Another mechanic told me that usually they have a kit the use with different measures to see which one fits better but as we can see everybody has his own method. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

OK I will do that and write down the measures. I will update you in the weekend. Thank you very much -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Thank you very much. I sent a message to @JamesG I hope he’s going to be able to email me the workshop manual so at least I don’t have to translate from Japanese 😂 question. What if I need extra shims to do the job? Is it possible to pick them out without removing the camshaft? I saw a video of a guy in Thailand doing it with a few accessories. What do you think? -

@Ryan-11 hello This thread goes way back but the problems to solve are the same. It’s so nice to see many people still loving these cars. I am in the process of solving a valve clearance after forging the head. Rectification has been done and they didn’t do valve clearance for me so I will have to figure it out. The only problem is that I don’t have the shims kit. How do you guys fix the gap when the shims are too thin? In my keys 1/10 mm has been rectified in that valve cup so apparently all shims should be thinner to close the gap. This is essentially theory because I still didn’t check for clearance getting the head cover off. The symptoms are lack of power in mid range and blowing noise that I thought was coming from the turbo. The other symptom is that the engine bangs when changing gear in acceleration. Let me know what you think. Other friends on the forum are already aware of the problem

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Yes we checked everything. The turbo is fine because the turbine is smooth and The turbine shaft has no movement. I guess the issue is that the valve clearance hasn’t been checked because the shop doesn’t have the camshaft and I didn’t know I had to do it. Never done this before and I don’t have the specification from Toyota to check clearance between camshaft and cup plates. I am so mad at myself because I didn’t know this and the shop didn’t tell me at all that I had to do it. They said that it’s normal that a mechanic is it gonna check the clearance after ratification but I am not a mechanic and my partner doesn’t have experience with this type of valve movement system without registration. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

My heart is bleeding. They could have explained procedure or just ask me the camshaft in order to do the full job in house. My partner didn’t know the engine and he expected me to know it all. I never went through this process otherwise we would have done it right. I hope there no damage and only tuning needed. Who has the official Toyota specs for the stock valves clearances with the full procedure? -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Can you please give me the parameters that the valve gap have to be between? -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Here now I just received the truth that apparently seems to be the issue. The valves haven’t been registered. The shop told me that they want to do it without the camshafts. My mechanic didn’t even think about it and put the head back on. I’m so frustrated. I really hope I didn’t bend and evolve or create damage. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

@Claymore is it possible that trimming the turbo side of the exhaust manifold would create a noise or change how the turbo CT9 works? Ever since we put the engine back together it is not behaving like before. It’s banging while changing gears and there are holes in the acceleration between 3000 and 3500 RPM. Mechanical timing has been set precise and electric timing has been set as default. What could’ve happened? -

Claymore's sleeper 4efe+t-t+t build (R.I.P. the Nanza)

Frankieflowers replied to Claymore's topic in EP91 Progress Blogs

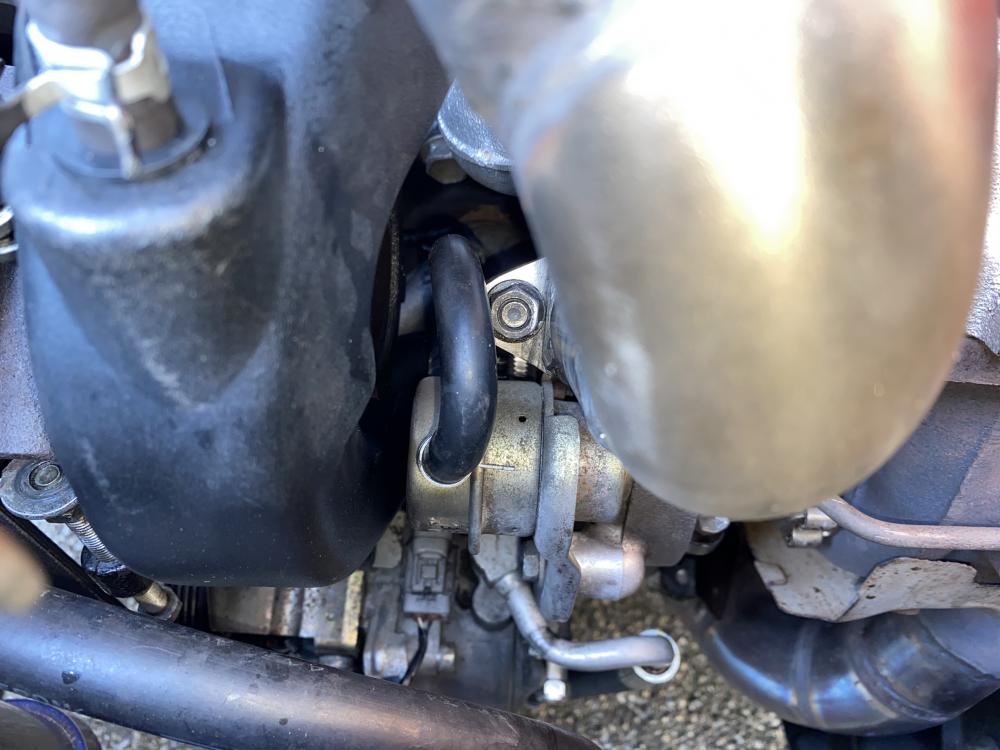

This is what we did we didn’t touch the bolt bumps tho we had to weld two small cracks that are visible in the picture. -

high pitch noise from turbo ????

Frankieflowers replied to 200bhp starlet's topic in 4E-FTE Engine Discussions

Could this cause loss of power between 3k to4k RPM? The noise I hear feels like air blowing high pitch but my pressure gauge (positioned on the hot pipe) doesn’t show loss of boost. What could it be? We removed the clamp on the efi for convenience purpose and put a screw clamp instead. Yesterday I checked if it was tight enough but it was OK. Also I think that this wouldn’t change the wastegate work in the turbo. I checked the BOV send screwed in a little bit the spring pre-compression I got nothing changed. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

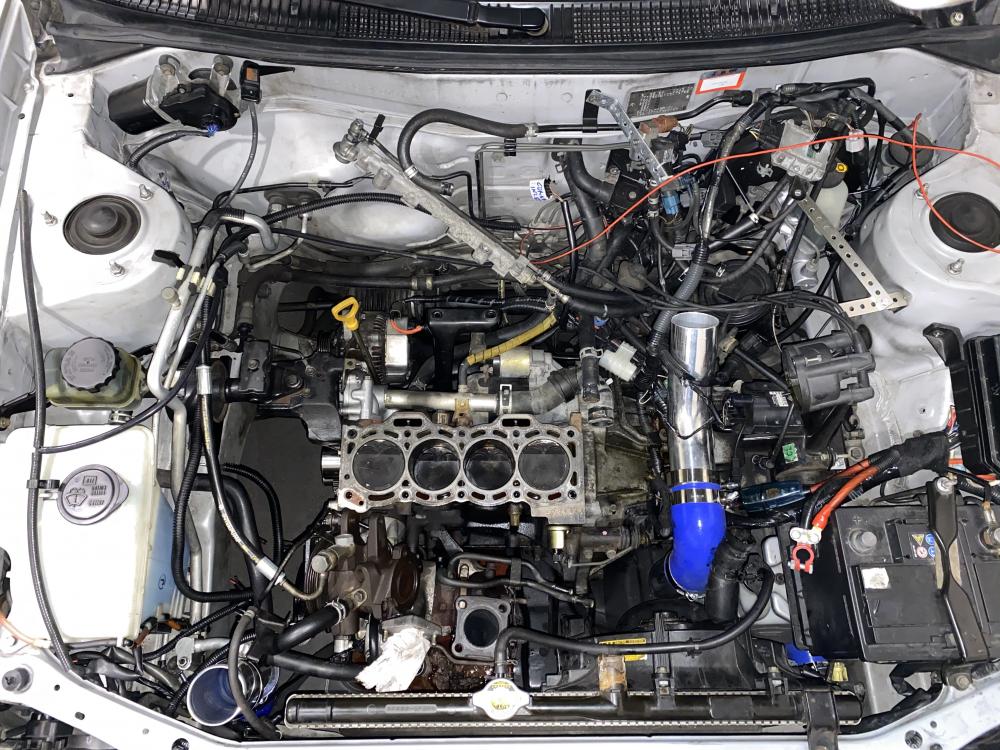

Here is what we did to solve the cylinder crack. We got the head off and sent it to get cleaned. Then sent it to get laser welding. We sent it back to get new valve gaskets on, Valves got cleaned and exhaust and low surfaces got cleaned I got the head back to the shop and cleaned the other parts Luca trimmed and welded a crack in the mani. We painted it and painted the head cover. New gaskets everywhere! New bolts for the cylinder head of course The engine sounds amazing. But there is a problem! When we first started the engine turbo turbo area was making a squeaking noise. At first thought the oil wasn’t getting to the turbo so the bearing suffered I am not sure about that. How could it suffer after five minutes with the engine on at idle? We fixed the timing in diagnostic mode to set it on 10 it worked fine but I didn’t feel much difference so I put it back to 0 The main issue is the blowing noise like for example the hard intake pipe in the turbo wouldn’t perfectly fit it? Or some silicon hose isn’t properly tight? I checked everything I could and thing is that the turbo isn’t expressing itself how it should and there is a few power drops between 3000 and 4000 RPM I don’t hear a metal bearing noise growing with the RPM I hear constant noise that sounds more like air is blowing from the intake for example? Probably the downpipe? We put new metal gaskets and new bolts and maybe tightened them less than what we should? What do you guys think? @Sam44 @Claymore @Jay -

Oil Pressure And Temperature Gauge Installation

Frankieflowers replied to Steve GT's topic in Electronics

I finally did it and it worked. IMG_5694.MOV -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

This is some thing I want to try. The spray technique is helpful to understand if the door shots 100%? What is the goal? Shutting 100% or leaving 1 mm open? -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

I still need to elaborate this and maybe see some pictures. It’s hard to test on a daily car. I have to be 100% sure that modifications will work. If I haven’t done it before and I have no precise data then I feel uncomfortable trying something new. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Do you have a description or some pictures of how this has to be done? The boost creep they are talking about worries me. What kind of pipe would I have to replace the EFI with? Silicon? Aluminum? There are many details I am not aware of to do the job before I put the engine back together tomorrow. -

@Sam44 @Claymore Hi. I would like to know if I will be able to lower the 2&3 custom exhaust mani restrictions without ruining it. The restrictions are the stud bumps that shouldn't be lowered.

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

You are telling me that I should remove the turbo plastic inlet to have more power but if I do it I will get boost creep. So why should I cause a problem if the ct9 has its own parts studied to be proportioned with the power needed? so if I get the plastic turbo inlet off, what should I put in the turbo instead? this is something new to me. If you tell me asap I will do it before I put that plastic inlet back on. Tomorrow we are putting the engine back together. Thanks! -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs