-

Posts

4744 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by RobSR

-

No worries, the physical injector opening time will tell the tale, but it sounds like with the DC you’re running at said boost you’d be very rich which would then also effect power. You say they checked the fuel pressure, which 9 times out of 10 is the issue on starlets on the dyno, I’ve had it easily on 5 cars when tuning them, you’ll keep adding fuel, injector PW goes up, but the lambda doesn’t read any richer as the fuel pump can’t keep up. It’s common and then you end up with a funny looking fuel table too. If they are certain the fuel pressure is fine and isn’t dropping on boost, it may be clogged injectors, or they may be calibrating against a Lambda which is reading massively wrong. Did you ever have your injectors tested?

-

Yes usually upto 330-350 ish at 1.7 bar on your turbo id expect Yes stock dizzy is fine at 300-350 too, when you start running higher boost levels the stock coil can struggle to give you the spark energy you need. N/A fuel lines also ok. Ask the guy mapping it what AFR and final injector pulse width you’re seeing at 1.4 bar around 6000 rpm. will PM you too.

-

Take the RT comment with a pinch of salt, you won’t make 345 @ 1.4 bar unless you have a very well built head. A 2860 usually makes around 350 with completely stock head (unported etc) nearer to 1.8 bar It sounds like the power may be a little low, however this could be caused by a lot of variables, including the ignition advance the mapper has decided to use also. For the fuel system, you need to check the various components, and get the injectors cleaned/flow tested too. Stock fuel lines with a FPR are fine again for 350+ bhp. Yes they are the injectors but the older version by the sounds, I can supply the newer 1050X variant if needed, but in most instances the Bosch CP ones will be fine .

-

They won’t reverse the result

-

You should not be maxing a 550cc at 240bhp so you may have other hardware issues on the car so you should investigate the complete fuel system. For a cost effective option I usually recommend the Bosch CP ones. From the time I’ve spent on the dyno with the 630’scc they usually will do around 350bhp fly on a 4E with GT28 but that’s pretty close to flat out on them at stock fuel pressure. You can get larger if required, for bigger turbo / higher power setups you can use the Bosch CP 1000s, but for best control on 95% of 350+ bhp car I recommend Injector Dynamics 1050x. For reference a 1000cc you can make upwards of 450bhp fly on a 4E (tried and tested and still not maxed out) Who was mapping the car? Did they look into any of the fuel system components to help you fault find?

-

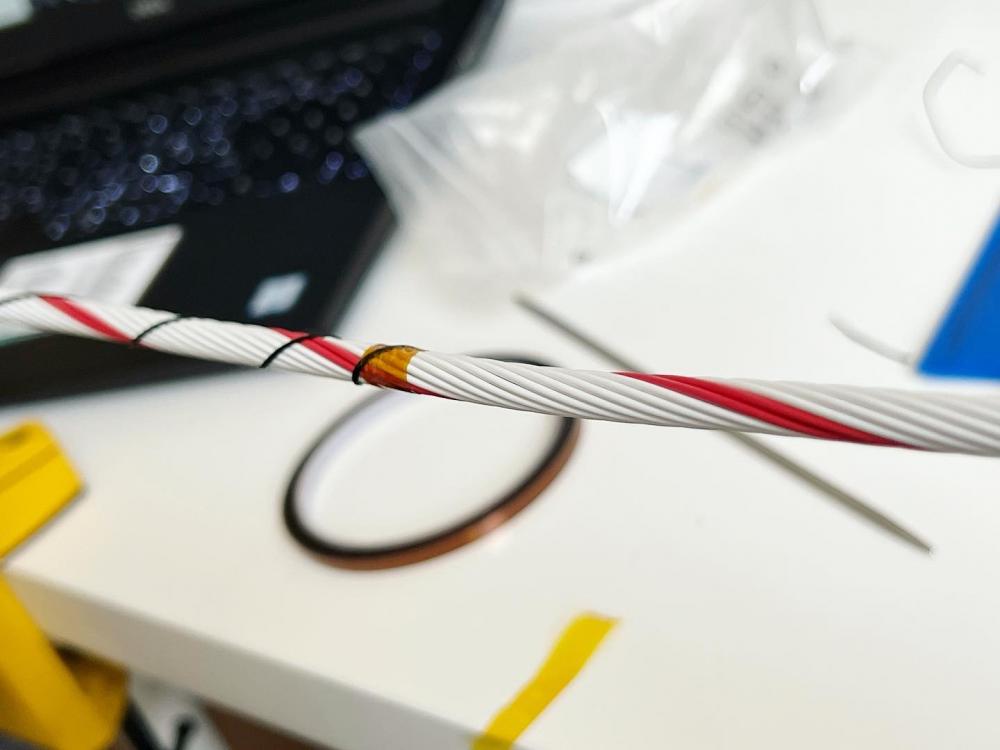

Thanks! They are called 'service loops' and serve two purposes really: 1. Strain relief 2. More importantly, if a pin gets damaged etc and it needs to be re-pinned, you can uncoil the service loop and you have a spare bit of wire to carry out the repair. As it'll be a completely twisted loom, you cant tug an extra bit through, so there for future servicing if needed. (shouldnt need to be, its a just in case)

-

What’s the 208hp run?

-

Yes makes sense, I think you are reasonable priced anyway so I think you could bump your prices a little to do the piping in Ali as it is better for heat management

-

Had a free 15 mins last night so started on the first connector on the ECU loom. Lots more pins and connectors to go.

-

Nice! I just don’t get why he still uses stainless for the piping rather than aluminium though!

-

I didnt say you did, however its a lot safer and driveability is miles better.

-

It should be fine yes. Haha don’t apologise, not your fault, as with any forum, it’s free speech as such so just different people giving their advice. Up to you whos you want to follow!

-

You’re saying it’s ‘impressive’ that I don’t need to know the exact FPR the guy is running - that’s because whatever FPR you run, the pressure changes based on the engine vacuum not the FPR - if someone fits an eBay / faulty / shit FPR that doesn’t alter the fuel pressure correctly based on the engine vacuum and boost - that’s not my problem. It’s all standard stuff, it doesn’t need to be over complicated. Talking of ‘impressive’ telling the chap to run 3.6 bar fuel pressure and it’ll make 200bhp is a bigger stab in the dark when you have no idea on his setup. The stock ECU runs stupidly rich with a CT9 on stock ECU with stock fuel pressure with bolt ons (decat, filter and exhaust) - they run flat 10s on boost, let alone doing that with 3.6 bar fuel pressure, it’s only going to get worse. This advice is the exact reason why @Patches has called you out above - rightly so too. Last CT9 turbo car I mapped made 200 bhp at the fly at 1 bar, guess what; it had a stock FPR so the base fuel pressure was no where near 3.6 bar - I wonder how that was possible? Oh yes, because the FP doesn’t need to be anywhere near 3.6 bar base

-

2.4 was with vac line on as most people test them with the car running so naturally the vac line is still on as with stock ECU you can’t really run the pump without starting it unless you go into the Diagnostics block, but as said, best practice you should set it with the vac line removed, in which case set it at approx 2.8 bar.

-

Traditionally you set them with the vac line off so you're setting the true base pressure

-

I split the turbo off the mani when it’s stock manifold, you can get to them all with swan leg spanner’s That’s then frees up a lot of room to get at the two underneath the manifold Always takes a while the first time you do it, then it gets easier You can get the crank on the head welded up, looks like it had been blowing there too from the colour

-

-

Stock is 2.4 bar

-

Forged daily build from 55kw to 200kw+ (2023-01 updated)

RobSR replied to MegstuBMW's topic in EP91 Progress Blogs

As Claymore said, a lot of people forget that if it’s still stock engine, you should use the grades Toyota suggest as the clearances were done appropriately from factory for this. We’ve all been there, years and years ago when I wasn’t fully clued up I wanged 10-60 in mine, it was fine but technically not the right thing to do even tho you’ll think it’s better. Fuel cut limiter is fine on 4E, they aren’t the biggest fan of an ignition cut tho (must engines aren’t) so that wouldn’t help if it you had your launch setup like that (again most do as they like the noise and flames lol) The ACL thing came about as you can get ACLs made in China (newer part #) and the original flavour made in Australia, they are different part numbers so there is a difference between the two. Ive used both in builds without issues however -

Thanks! Look forward to get it running too! Still plenty to do mind

-

starlet interior parts for sale / clearout

RobSR replied to snails ep91's topic in Starlet Parts For Sale

Hope snails doesn't mind but I have engine loom available if needed -

Essentially yes, you ‘fill and empty’ the pressure in the dome of the wastegate to maintain your calibrated target. The canister is there and is fed via a one-way valve so it stores positive pressure so it’s available when off throttle / when the turbo is choked (unlikely to happen in my setup with no restrictor etc) but the theory is similar to that of a Co2 setup, but I’m recycling boost pressure not using Co2 Further more, 95% of the ECUs on today’s market that use dome pressure control can only use that for the boost control strategy (Fueltech for example disable the MAP target part when using dome pressure control) whereas on mine I can have a dual MAP and Dome pressure control target so the boost control should be spot on. Yes will post IC efficiency results when it’s done as I have pre and post temp and pressure so can all be logged correctly - no ‘assumptions’ here!