-

Posts

418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by Frankieflowers

-

That’s cool. So I cleaned it with a product and the ticking disappeared. But then I gave some gas on the throttle with my head close to the engine and I heard that the ticking I hear from the cabin comes from the exhaust manifold. So this must be caused by a crack in the manifold or in the downpipe. I read this around and I was hoping it wouldn’t happen.

-

I did so and it stopped ticking while rpm raised. what shall I do now? Should I buy a new one or can I repair? IMG_5371.MOV

-

I will try to unplug the black hose and see if something changes. Thanks.

-

Hi guys. My engine starts ticking not on idle but when I start driving it and I press the throttle. It does it for a few hundred meters (around a minute) and then it stops doing it. If I give more gas the engine is not running properly. As soon as the ticking fades everything turns to normal. It does it when I fire it in the morning and it’s still does it when the engine is warm. At first I thought it was the oil missing on top of the engine for the valves hydraulic but I am not sure and I would like someone to help me find out. Thanks.

-

Hi guys. My engine starts ticking not on idle but when I start driving it and I press the throttle. It does it for a few hundred meters (around a minute) and then it stops doing it. If I give more gas the engine is not running properly. As soon as the ticking fades everything turns to normal. It does it when I fire it in the morning and it’s still does it when the engine is warm. At first I thought it was the oil missing on top of the engine for the valves hydraulic but I am not sure and I would like someone to help me find out. Thanks.

-

Oil Pressure And Temperature Gauge Installation

Frankieflowers replied to Steve GT's topic in Electronics

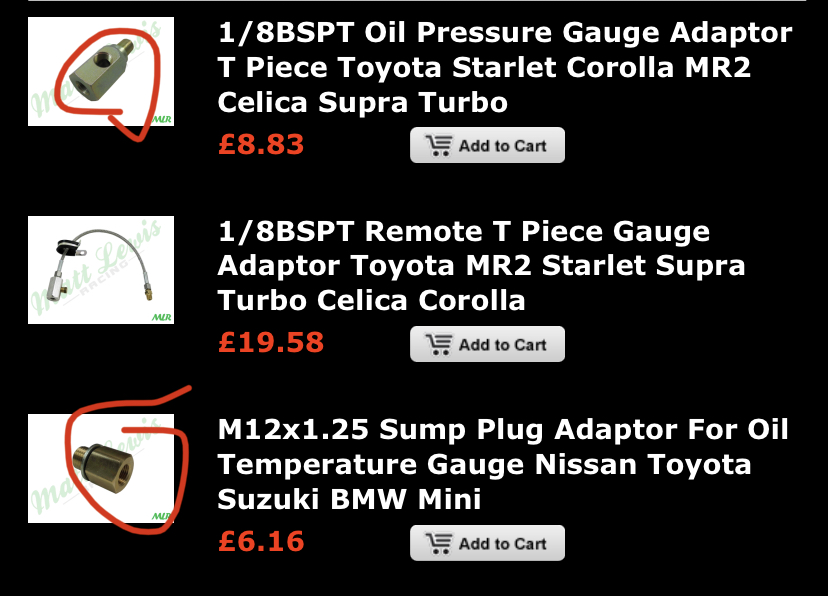

Thank you for the explanation. How much does this kit cost and how much did you have to work on the bracket to make it fit? -

Oil Pressure And Temperature Gauge Installation

Frankieflowers replied to Steve GT's topic in Electronics

So I have been thinking about this option and after asking here and there they told me that it wouldn’t be proper because the oil wouldn’t be able to move through the pipe properly like it does in the sandwich plate. This wouldn’t permit a precise temperature and pressure reading. They basically said that it isn’t a good option. I was hoping it would work because I would get out of my oil filter area and belts. I hate to move around that area and have to compromise them with oil all the time. The other option is to relocate the oil filter with the special pipes for a future oil radiator. It is more expensive though. So I bought another sandwich plate and I am waiting for my partner to be patient enough to get the bracket off then try to make it fit without ruining it. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

There is something I wanted to ask you guys. As soon as we swapped the engines and tested it I noticed that there is a valve ticking when opening throttle.it disappears after a few hundred meters drive. Logically it’s oil missing on top of the engine that needs some time to work properly. I want to ask you why it happens and what should be done to be fixed. Please notice that whenever I start driving and I am patient a few hundred meters it’s starts to fade until I feel the full power and I can drive normally. my brother told me that he had the same situation with his 1996 Volkswagen golf GTI 16 valves. what do you think about it? @Claymore @Sam44 -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Here I am for an update. So technically I don’t know the size but it must be a stage 2 size. I couldn’t read it on the intercooler but I must check again to let you know. I called the company that does special aluminum welding also with laser in case I needed it. They checked it with the liquids and found out a little crack and went on the original welding lines to make sure it was OK. I went home and put it back on. Here’s the point. When I put it back on I realized that the intake side silicon didn’t have both sides hose clips. My partner and didn’t put it on every point because he thought it would stick enough without it. So I added a hose clip where mossing. I went for a test drive and I was amazed that the engine was back to normal. Of course the feeling was different but I had my power back. Suddenly I heard a bang and I was pretty sure that silicon silicon hose popped off. So I went to put it back on and I went for another ride. I heard another bank end it was another silicone hose without hose clip. So I put the hose clips where they were needed and they fix the problem. But then I left town and after a few miles I heard air blowing. When I got to destinations I checked and I found out that the silicone hose was not in the right position. So I had to take the bumper down and fix it. I went for another drive and I felt air blowing so I was pretty sure it was the old Toyota BOV hose. I kept the same hose for the pop-off. But because I changed the hot pipe the hose wouldn’t fit properly because too old and hard. So I found an extra hose clip and I fixed that as well. No the car works perfectly. Next step will be changing the ECU with a EMU CLASSIC. That is when we will see if the whole investment will be worth it. -

Claymore's sleeper 4efe+t-t+t build (R.I.P. the Nanza)

Frankieflowers replied to Claymore's topic in EP91 Progress Blogs

We figure that out as well while swapping. There weren’t extra wires and extra connectors. I agree that there is some confusion in the manuals and in the echo pinouts. We could have saved precious time but we knew that we were pioneering a swap that only a few people there then they apparently went silent. @Sam44 in one of his first descriptions he made for me mentioned keeping the Corolla 4EFE inlet throttle that in his opinion is more efficient. Again at it was a big amount of work we kept these upgrades for the future coming. So now is the time to understand what can make the engine better. Reading this thread that I have seen before I understand better that there are some defects that can be fixed. It’s just a matter of doing it properly. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

We will get more into the exhaust manifold topic later. First I want to tell you what I did today. so I told you that as soon as I tried the car after installing the intercooler and the new set up the car was completely different. I didn’t feel any weird noise but there was just no power. We got to this point already. my partner was busy with work because we have a shop and he told me to wait after New Year’s Eve. I am pretty stubborn and I have to leave tomorrow to see my girlfriend in the fields and I definitely didn’t wanna leave with the car running like that. I didn’t wanna wait. it went in my garage and took down the new front bumper that you don’t want to torture too much because it’s fiberglass and I just spent loads of money to make it nice and painted. I took it off and I took down the intercooler. I was lucky to find a company that does professional soldiering and has many important clients in the car business. So I went there and they analyzed it and noticed that there was a little crack but just to be sure they welded every main welding from scratch. In amazing job. I had the feeling that it wasn’t just that because it tiny crack won’t reduce much power and I knew there was something else. when I got home after dinner in the cold I went back down in the garage and put back on the intercooler. First thing I noticed is that the right silicon hose wasn’t tied on the external side. So I took one of my nice ABA hose clips and put it on. I checked the left side IC input where are the 290° hoses touch each other and it looked like the steel clip was keeping them both joined on the aluminum cut we made to keep them together. So I put the bumper on and went for a ride. Wow! my car was back to be what it was before! Wheels were spinning in every gear. So I went on the main road and went for gas. I was so happy! On the way back suddenly I heard like a balloon blowing and I was like f###! I was hoping it wasn’t anything bad but I knew it was a hose that blew off a pipe. So I stopped and I checked. I was right. I noticed that the 90° that gets out of the new hot pipe didn’t have the steel clip on the external side. It was completely off so I put it back on. I went for another ride and boom again! I stopped again and I checked. This time the 90° that gets out the intercooler on the left side blew off. Yes, the steel clip wasn’t keeping them together but only one of them. So I put it back on and went home. I took a few steel clips and put them on where they were missing. I didn’t blow off again but I still feel a whistle that might be one of the steel clips not tight enough. I know you guys have a lot of experience and I don’t but I have intuition. I knew this wasn’t about intercooler set up and the turbo lag. I am very happy that I can enjoy the car before installing a new ECU and tuning it. Tomorrow I will go see my partner and I will explain what happened and I will make sure he checks every steel clip before I leave town. @Claymore @Sam44 -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

You pointed an arrow on our custom hot pipe. What do you have to say about it? It does exactly what the other half pipes I’ve seen do. Thanks -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

You pointed an arrow on our custom hot pipe. What do you have to say about it?? It does exactly what the other half pipes I’ve seen do. Thanks -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Which custom manifold do you suggest to buy? -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

The engine was perfectly fine. We just installed the pipes and the intercooler. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Apparently there are no air leaks. The intercooler isn’t oversized and maybe it doesn’t get enough air but it’s shouldn’t have dropped power drastically. Boost lag is noticeable and I see it on the gouge as well. I am basically one point lower compared to before. Please tell me more about the fuel regulator and how I could fix this before changing the ECU and mapping. It will take some time before I do that job and I want to have my power back. Thanks -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

I bought an intercooler but I ended up installing a smaller one because it would fit better and I was hoping it would have less turbo lag as some friends advised. My goal is to change the echo and map it for daily use. As @Sam44 once said do you don’t want to go higher than 180 hp for a daily you. This said again I don’t understand why I had big power drop of power even if everything is attached properly and my pipes are shorter than the usual Starlet setup. I went straight down to the IC from the turbo instead of going all around like the Starlet FMIC do kits do. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Apparently there are no air leaks. The intercooler isn’t oversized and maybe it doesn’t get enough air but it’s shouldn’t have dropped power drastically. Boost lag is noticeable and I see it on the gouge as well. I am basically one point lower compared to before. Please tell me more about the fuel regulator and how I could fix this before changing the ECU and mapping. It will take some time before I do that job and I want to have my power back. Thanks -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Where do I connect the boost gauge? Which pipe? thanks for your comments. I am trying to figure out why I had a drastic drop of power. Everyone wrote that with a decent bigger intercooler and correct pipes I would have a 15% gain of power especially in the mid range with the original CT9 turbo without mapping. The turbo lag it’s quite important now and I lost the power that would make driving exciting. So it is obvious that if I change the turbo or get this one refurbished and wider inside with the bigger rotator (if that is the name) and obviously a brand new Achoo and map I will have power. That is in my project but we are talking about €1500. I was hoping that with the money I just spent I would have a good feeling and at least the same power. -

Oil Pressure And Temperature Gauge Installation

Frankieflowers replied to Steve GT's topic in Electronics

Thank you for the drawing. That is exactly what I would do but it comes out that there is no oil circulation off to get the temperature accurate. -

Oil Pressure And Temperature Gauge Installation

Frankieflowers replied to Steve GT's topic in Electronics

I have the suspects that with no oil circulating it would be just approximate temperature. You’re not the first one who says that but I was hoping not to shave the steering pump bracket. So tell me more about how you relocated the oil filter who is the cooling system that if you have pictures. I would rather relocate the oil filter and get it out of that nasty corner too close to the belts. I had oil all over the place because of my sandwich leak that was caused because I shaved it. It worked for a few months but then it started to leak. I hate to get the bracket off and shave it. Maybe it is better to put a an oil filter cooling relocation kit. -

Oil Pressure And Temperature Gauge Installation

Frankieflowers replied to Steve GT's topic in Electronics

This will work without making a hole in the pump bracket? I feel it’s the cleanest job I could do and get the pressure sensor i. The OEM location with the adaptor. Any idea? -

Oil Pressure And Temperature Gauge Installation

Frankieflowers replied to Steve GT's topic in Electronics

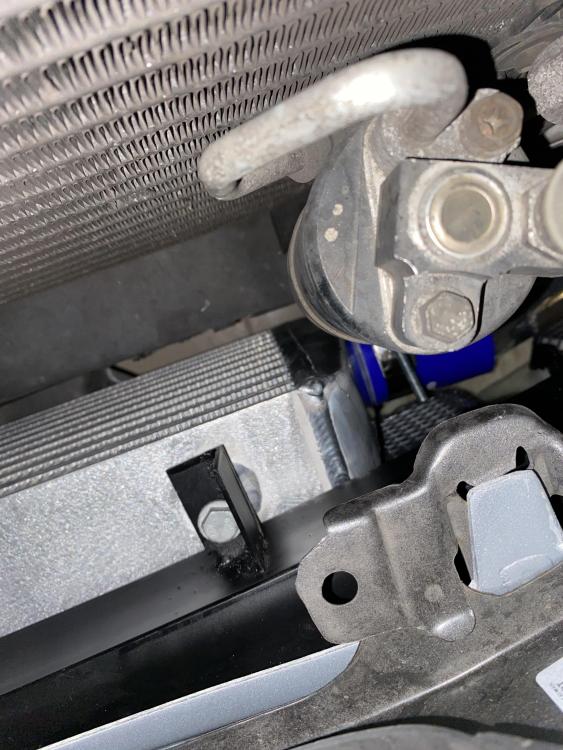

Did someone try this sandwich on the turbo engine with air conditioning? I have to be sure nothing have to be trimmed. If this won’t work then I will have to abandon the sandwich plate and go with the less safe adapter extension in the OEM oil pressure location and attach both adapters like in the picture the oil temp sensor won’t fit with short adaptor in the blanked spot on the relocation oil filter bracket Any idea? -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Definitely the pressure gouge isn’t precise. I have Bres with what you are saying. The only thing I feel is less power in the mid range like before where wheels would spin also in third gear. This set up is definitely more professional and ready for a new ECU Master (EMU Classic) and brand new map. That will be the next step. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Frankieflowers replied to Frankieflowers's topic in EP91 Progress Blogs

Let me know. I remember you telling be I would gain 15% power in the midrange.