-

Posts

660 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by Claymore

-

Nice work as always mate. Nice to see the fire sleeve and the bracket to stop it getting munched by the clutch release fork!

-

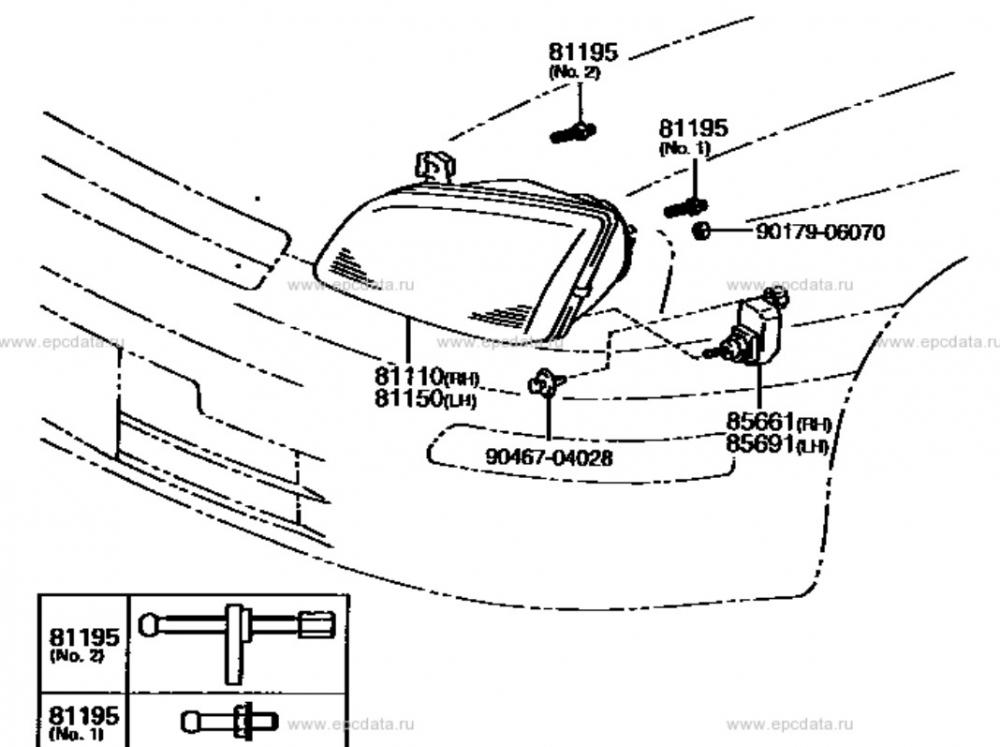

Hope this helps, picture is from an online Toyota parts catalogue. Looks like a single bolt to hold the levelling motor in. Also, most of the photos in this thread aren't visible, just links.

-

It's only fair that I get to respond. The manual(s) I quoted from are both Haynes manuals as stated on the previous page. I did ask someone to check the official Toyota manuals with Jay. I'm happy to use the figures I quoted, I've always found the Haynes manuals to be reliable. I do know how a fpr reg works (we have already discussed it on the threads where you suggest using a reg set at a fixed 4 bar (un referenced) for turbo applications. 😵). I also seem to remember having to explain to you how / why a 1 bar map sensor does or doesn't work on N/A+T builds on another thread you started so I know the feeling of educating children also. No offence to you either. I don't take any pleasure in having these types of discussion, it's not who I am at all. The DET3 piggy's use 16x16 tables, same as the emanage blue from the info I can find. I think the rest has already been covered in previous replies by different people as well.

-

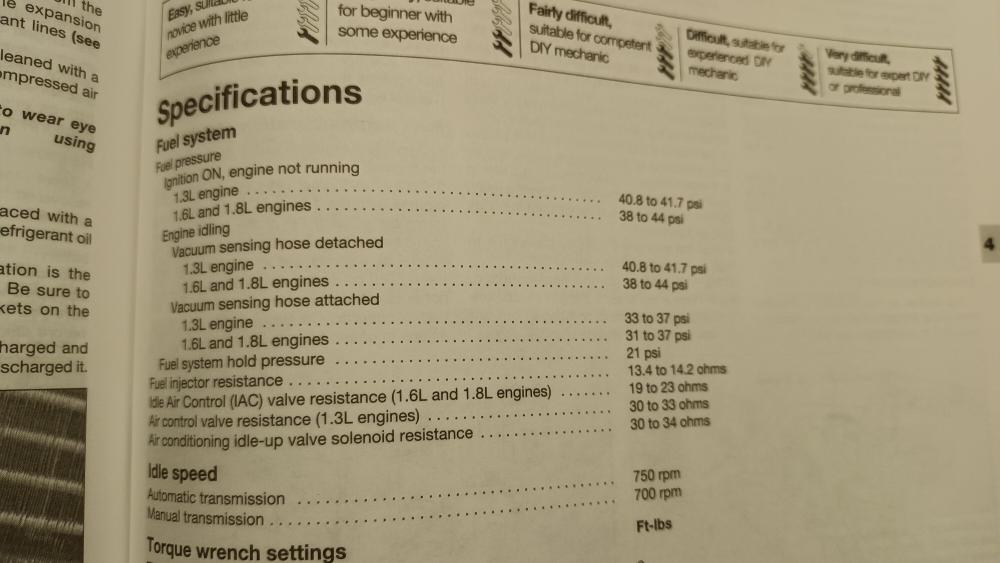

The workshop manual figures I quoted state the fuel pressure should be 2.8 bar base and anywhere between 2.27 and 2.55bar (average 2.4 bar) with map reference attached. Any how, recommending that other people use 2.5-2.7 bar referenced is at the richer end / over stock pressure not lower than is specified in the workshop manual. It is obviously lower than your readings of your car with your gauge. If yours is running 3bar with reference, that is already well over stock figures (max 2.55bar), maybe your car has a fault. Or maybe the fp gauge your using reads over? All I am saying is this method of "tuning" is best described as crude and no one can argue that more accurate fuelling control wouldn't be achieved with a piggy back and WBO2 combo. It's all about how much compromise someone is willing to accept. There's a lot of options when it comes to tuning and I wouldn't take certain routes. Other people are free to try whatever they want and please report back with dyno figures including an AFR and MAP trace.

-

This 👆. A working / good quality 1:1 ratio fpr will increase or decrease fuel pressure the same amount as the MAP changes. That's the whole point of a reg. This sounds a lot like back tracking after what was said on Callum's build thread where you proposed adding larger injectors and lowering the fuel pressure? Now you want larger injectors (more fuel), higher base fuel pressure than stock (more fuel again) and a reg that doesn't increase fuel pressure much to reduce fuel at WOT because otherwise it runs pig rich due to being open loop? This sounds more like a bodge every minute and what if you get a fake fpr that actually works at the correct ratio of 1:1? Pig rich WOT. All I'll add is, if your planning on adjusting fuelling my advice is to install a wideband O2 sensor first or get it checked on a dyno. The Det 3 + piggy back ECU is so cheap it doesn't make sense to bodge stuff anymore. Especially when you consider that it also adjusts timing, datalogs and with the addition of a mac solenoid it can adjust boost levels via a PWM table. £250 new for a piggyback, datalogger and EBC all rolled into one.

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Claymore replied to Frankieflowers's topic in EP91 Progress Blogs

If it was my car I would get a set of ARP head bolts to use when re fitting the head. It's the ideal time if the head has to come off. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Claymore replied to Frankieflowers's topic in EP91 Progress Blogs

Can't remember exactly how I did it, but I definitely installed the turbo to the manifold first. Then installed the manifold with turbo onto the engine. -

Just to add my research to this thread for 4efe. Have not measured on an actual vehicle yet. The 4efe (gen 2) Starlet 96-99, 4efe (gen 1) corolla 92-97 and 4efe (gen 3) corolla 97-99 and 5efe Paseo 95-99, all list the same fpr part number (23280-11070). There is no Starlet Haynes manual but there are for the 'rolla's. (92-97 rolla shown below) Both Haynes manuals show a base fuel pressure of about 2.8bar and manifold referenced fuel pressure at idle of about 2.4 bar. That is what the Haynes manual states is correct. Can't say for the 4efte as it uses a different reg (23280-11040). If someone can ask Jay on the other forum (I'm not a member), he may be able to check in the official Toyota workshop manual he has for the Toyota 4efte data. Let's not forget the age of some of these Toyota fpr's and fuel systems aswell (clogged filters, weak pumps, clogged returns etc.)

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Claymore replied to Frankieflowers's topic in EP91 Progress Blogs

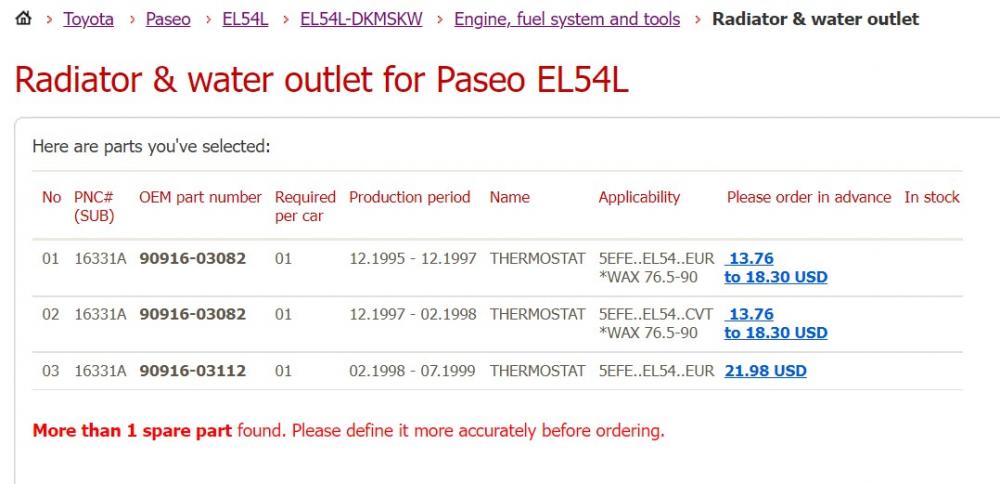

From the online parts catalogue I use: Doesn't say deg c in the description but neither did the ep91 listing and the Starlet thermo is marked 82 deg C so it's a safe bet. -

TURBOROLLA (4efe to 4efte ep91) SWAP

Claymore replied to Frankieflowers's topic in EP91 Progress Blogs

From memory to access the turbo to manifold nuts I needed to use offset spanners: Most people remove the manifold with the turbo still attached to it because the bolts are hard to access. In my experience the Toyota EP91 4efe/4efte thermostat (90916-03046) is stamped as 82 deg C which is what I removed from my engine. The Toyota epc states 82-95 (I assume this is starts to open at 82, fully open at 95). Found the euro Paseo 5efe 95-97 thermostat (90916-03082) rated at 76.5-90 deg C -

TURBOROLLA (4efe to 4efte ep91) SWAP

Claymore replied to Frankieflowers's topic in EP91 Progress Blogs

If you scroll up to the top of this page I already did. 😉 Click on the link and it will take you straight to that page of my build thread. The lumps in #2 and #3 runner are the worst. There is a small amount to remove from #1 and #4 but they aren't that bad. Happy grinding! -

TURBOROLLA (4efe to 4efte ep91) SWAP

Claymore replied to Frankieflowers's topic in EP91 Progress Blogs

First I would check that the manifold is actually cracked. Sometimes a damaged / leaking gasket can cause the same noise. You need to inspect the manifold for cracks. Look for black soot marks on the manifold and head. You can also hold a piece of tissue next to the manifold / gaskets and watch to see it blow as you move it around different places. As far as manifolds go I would avoid all the cheap stuff on eBay as it usually doesn't fit the engine very well and cracks very quickly. The CT9 Tubular manifold Tuning Developments sells seems ok as the first upgrade, hopefully someone using one will comment on its fit and function. If you want the top level then WEPR make excellent products. But not sure how they will fit in a corolla engine swap vehicle. Or you can try and find a second hand item from wepr, race tech, zisco but these are probably quite rare in Italy. The question is do you want to upgrade to TD04l or stick with CT9 / hybrid? 😈 -

Forged daily build from 55kw to 200kw+ (2023-01 updated)

Claymore replied to MegstuBMW's topic in EP91 Progress Blogs

When I removed the sump on mine I noticed that the corner of the top lip was bent from tapping in a screw driver to brake the seal. Managed to hammer it back flat again. They do sell repro EP91 style pans on eBay for about £50, not sure on the quality or fitment though. Might help if a Glanza one is unobtanium. -

No worries, didn't think that for a moment .

-

Forged daily build from 55kw to 200kw+ (2023-01 updated)

Claymore replied to MegstuBMW's topic in EP91 Progress Blogs

Didn't know that there were different versions. Thanks. -

Unfortunately I don't think 210cc will be big enough for turbo applications unless you're running low power. There are many online fuel injector size calculators that will help choose the correct flow rate and also calculate the increase / decrease vs the fuel pressure also. Not sure if you're talking about direct injection when it comes to spraying on cylinders. I was referring to port / manifold injectors and their nozzles. The changes in design over the years from single spray to Bosch disc type with 4 small ports (mx5 etc) https://www.witchhunter.com/spraypattern1.php

-

No worries, just trying to help. I love your enthusiasm and your willingness to help the Starlet community. There's plenty of topics relating to n/a tuning on this forum. Might be worth a read mate. Sorry for the tangent.

-

Sorry Callum.

-

If we're talking stock engine / with corolla manifold I wouldn't bother increasing injector size (the 195cc are plenty big enough), if you're talking about adding the same size injector with the same resistance but a better pintle design / spray pattern than denso I could see that working. The problem with just "dropping in" injectors is that the ECU doesn't know the size difference. When running in closed loop the narrow band O2 sensor will adjust the fuel that is delivered with short term and long term trims (assuming it has the the range to do so) but in open loop (full throttle etc.) afaik the ECU will use a generic lookup table without referencing the O2 sensor and not know if it's rich or lean. If you add bigger injectors you will most likely run rich at WOT probably losing power. You would need a wideband O2 sensor to read the rich/lean condition in open loop and at least an adjustable fuel pressure reg to compensate the fuelling (caveman style.) I would use a piggyback (det 3 is about £200) that way you can control the fuelling to a reasonable level. If it's research on injectors you want there's tons of it out there: https://www.toyotagtturbo.com/community/index.php?threads/interchangelable-injectors.58014/

-

Forged daily build from 55kw to 200kw+ (2023-01 updated)

Claymore replied to MegstuBMW's topic in EP91 Progress Blogs

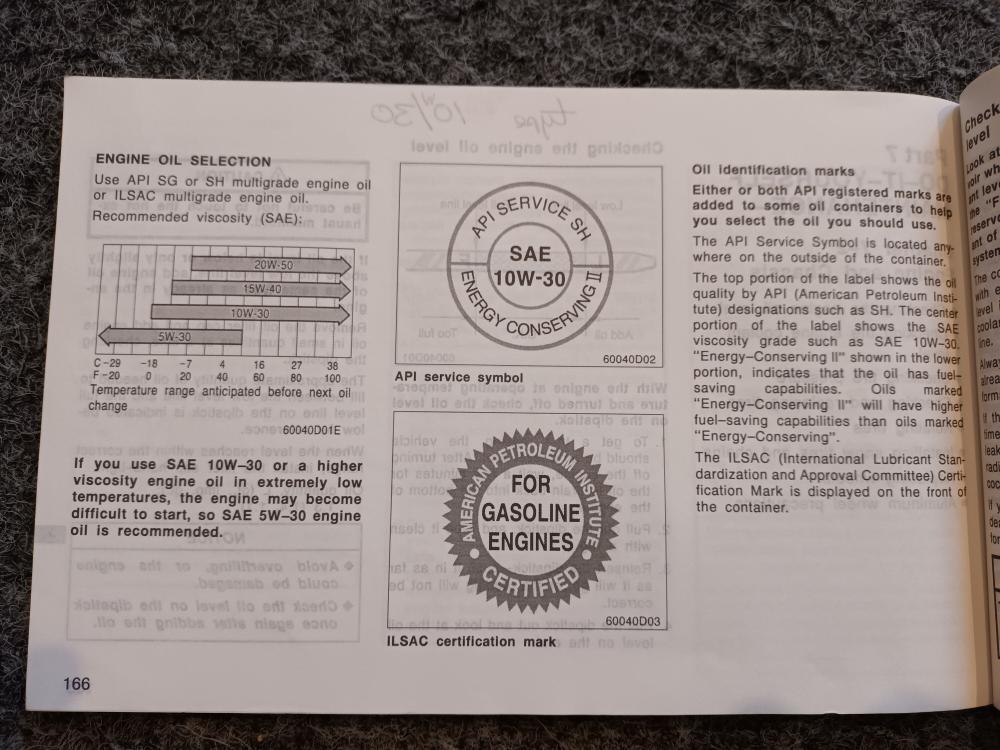

Not sure the oil grade helped, according to the 4efe owners manual the recommended oils are shown below: Most people seem to run 10w 40. The tolerances for the engine will be designed to use a range of oil grades but straying from this can lead to problems. When increasing grade the oil pressure should increase also but flow must surely decrease. The bypass valve may be able to even the pressure out though. I would say from comparing them to some online charts that it looks like fatigue failure and / or lack of oil / too tight oil bearing clearance. Detonation is a real possibility (Matt berry's Youtube video mentioned this). They don't look to have got that hot (not blue) but could have lead to disaster. I also found references on the forum to bearings and that some prefer the genuine Toyota items to ACL, although there must be plenty of 4efte out there with ACL. Toyota bearings are available in more sizes than ACL. Were the bearing clearances correct when you built the engine? -

Cusco brace looks great Callum. Can I ask what the yellow injectors do for an n/a? What size are they?

-

TURBOROLLA (4efe to 4efte ep91) SWAP

Claymore replied to Frankieflowers's topic in EP91 Progress Blogs

Check the idle control valve as the topic you quoted says. Unplugging it will help isolate if it's the cause. If it's not that, it could be the valve clearances or injectors tick as well. But neither of these usually get that loud. If you do have low oil pressure at start up that needs to be fixed. Some use a mechanics stethoscope to listen to different parts of the engine but I've always used the "long screwdriver to the ear" method. It helps identify the source of sounds very well. Be careful not to hurt your ears / hearing though! -

Kev's EP91 Glanza Rep Build - HOW TO DO A 4EFE CLUTCH CHANGE

Claymore replied to Keviano27's topic in EP91 Progress Blogs

Sorry to see you go, your thread was well written with good detail for others. Take it easy -

Already gone lol.

-

https://www.ebay.co.uk/itm/133985373556?hash=item1f32268d74:g:Hd0AAOSw4KRh1hRM No connection, obviously needs work.

.thumb.jpg.52dab960c440be1d6a49dcffc0152df7.jpg)