-

Posts

1487 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by Sam44

-

The intake runners are slightly longer than on the 4efe, other than that its pretty much the same. I'll do a side by comparison as soon as I get home. Yeh the electrical plugs are different for the intake air temp sensors. The one I have here is off a ep91 1997 glanza v, it has a gray plug, but I've tested both at different related temps and the readings are identical. I've reduced intake air temp by around 20degC. This will help the 4efe plastic sensor reading and service life expectancy, as well as engine torque output.

-

Claymore's sleeper 4efe+t-t+t build (R.I.P. the Nanza)

Sam44 replied to Claymore's topic in EP91 Progress Blogs

Fantastic information. Definitely, making hybrids is hard because you can only combine compressor maps and best estimate the hybrid design. The holest and Garrett are a more developed turbo in the evolutionary design and use. These turbos play better with power delivery/control. -

Modified 5e intake manifold to house the 4efe intake temp sensor. The more robust 4etfe intake air temperature sensor (thermistor) does share the same resistance values as the plastic 4efe unit and is threaded so can be used.

-

Claymore's sleeper 4efe+t-t+t build (R.I.P. the Nanza)

Sam44 replied to Claymore's topic in EP91 Progress Blogs

Yeh the heat range 7 are needed around 1bar of boost, but play havoc with engine exhaust emissions. The E3 range of plugs can comfortably take 1bar with the equivalent NGK heat range 6. Nice information in your previous post. -

Very interested in this if you get any more information or decide to give the turbo a try. I'm currently running a td04l hyb and I'm trying to get the surge of power as the turbo switches on down, as well as hold the engine torque up by reducing back pressure, but it's a balancing act. I'm thinking of running the tdo4hl exhaust turbine & housing with the 11 blade aftermarket turbine wheel which is quite a bit lighter than the 9 blade td04l I'm currently running now. The exhaust housing on the hl turbo is wider in the shell also I've got 1 here. From what I'm reading the holset turbo seems to be the balance I'm after.

-

Nice I've space out the rears at 10mm and I use 205 wide tyres on the rears, with the arch lip removed, but it's so close to the arch made a hell of a difference to the handling. I have a second starlet here I'm playing with the idea of doing a track car. Thanks for the reply and ideas. Great work.

-

The issue I had was the inline diode pack on the wiper motor loom/plug. I'm not to sure what or why it's there, but the bar fouled it to the point it would not fit. Nice engine bay by the way.

-

-

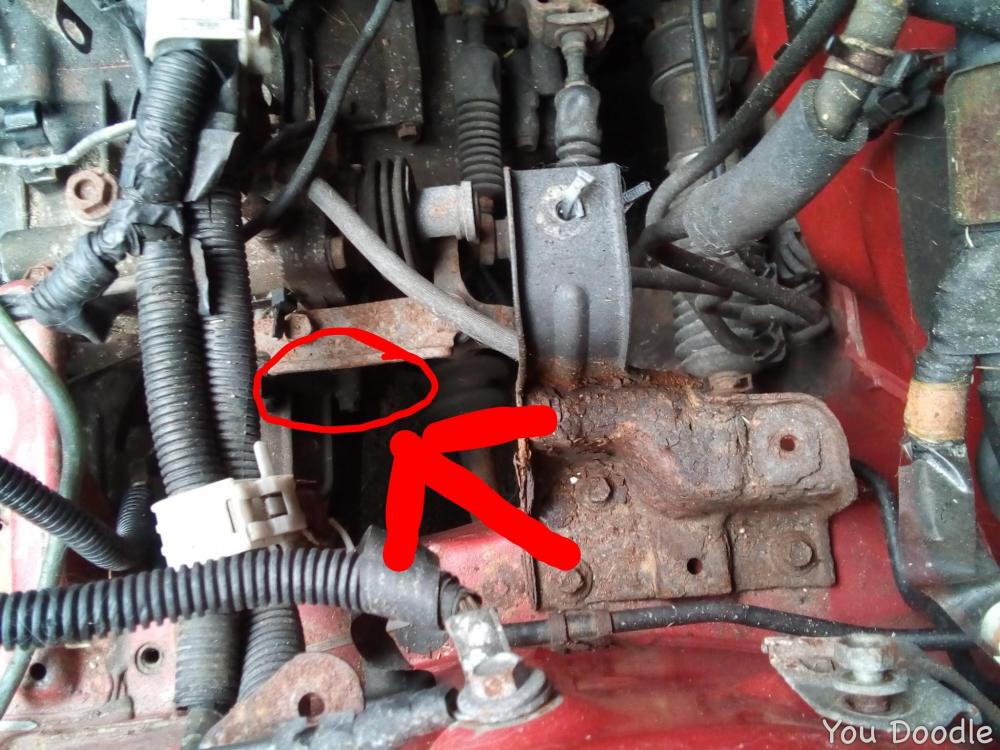

No. There positioned in the casing against each selector shaft behind a flat Allen key screw. It's a spring in a cup with a ball bearing. I'm back. I'll add a pic from my spare starlet I've got in Oxfordshire. This is a c60 box but there all in the same place. There are 2x more under the selector arm. This is a repair any 1 can do if you want a better gear position feel (stronger in and hold position). I did this to help me feel the gear position better. And at first mine kept kicking out of third. Forgot I had this Yaris desile box in the garage. You can see the 2x under the selector arm.

-

I was just updating myself on the gearbox build. I had the sixspeed gears ceramic beed polished/case hardening. Nice work. Another thing I did was to stretch the gear position locking springs around 5mm to help locate and keep gear. Mine had squashed with use and felt sloppy in position (weak).

-

I'm looking at flaring the arches front and rear, so as to extend the width of the wheel track. I bet it's 1 hell of a mod on these.

-

Tell me more I've just watched alot of the videos you have. Great watch pongratulations.

-

Thanks skinny, I'm starting to really pull apart the little starlet and find them production items that require tweaks. The beauty with these cars is nearly everything is adjustable unlike all of todays modern cars.

-

Search blink code readout, this will give you the fault codes if any are stored. Then setup ignition timing (checking cam timing) and check dizzy cap and rotor arm. Check your earth points on the chassis for corrosion as well as the map sensor pipe for muck (there is a inline filter in the pipe also check this the sensor will run fine with this removed). Make sure the intake air temp sensor is in its place. If you have a multimeter to hand we can check the coolant temp sensor and intake air temp sensor values (engine cold) as these can some times be off resulting in no blink code being set. Another thing to check is exhaust flow/pressure at the tail pipe, put your hand over it to see what the pressure is like (blocked cats and backbox problems).

-

I feel your pain tried it myself. Lol. Modding time.

-

Yeh I second that. I'll message you soon about what we spoke about. Im crazy busy at work I'll be back in a few week for a weekend. Great to see you back modifying. sorry to hear about your health, there's nothing like a project to help take your mind off things, just take your time.

-

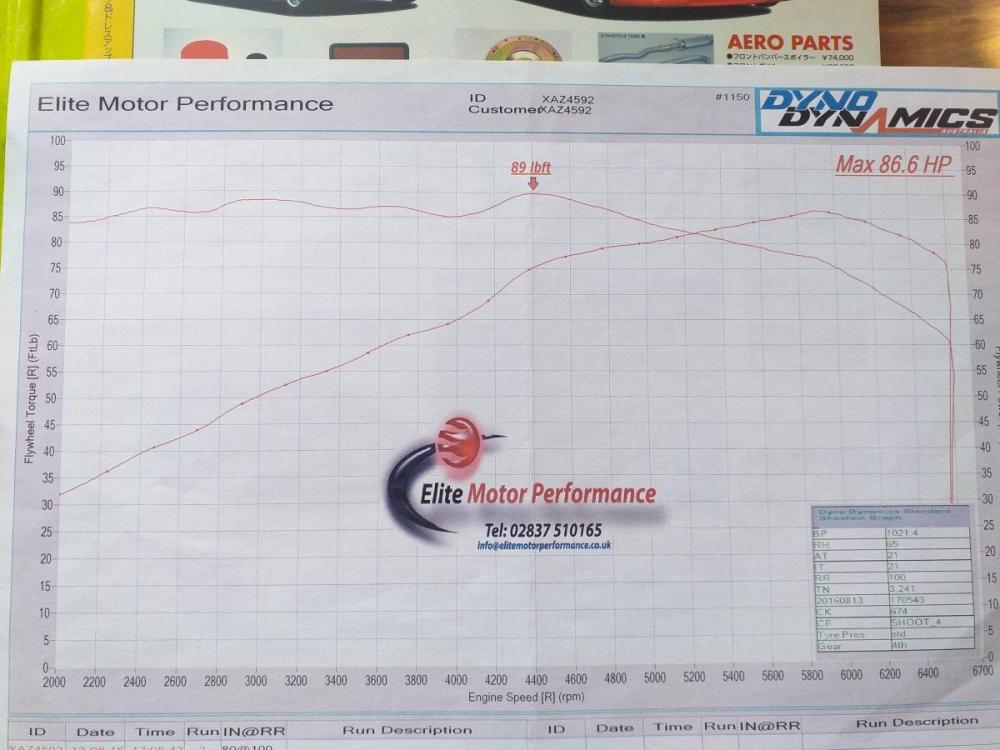

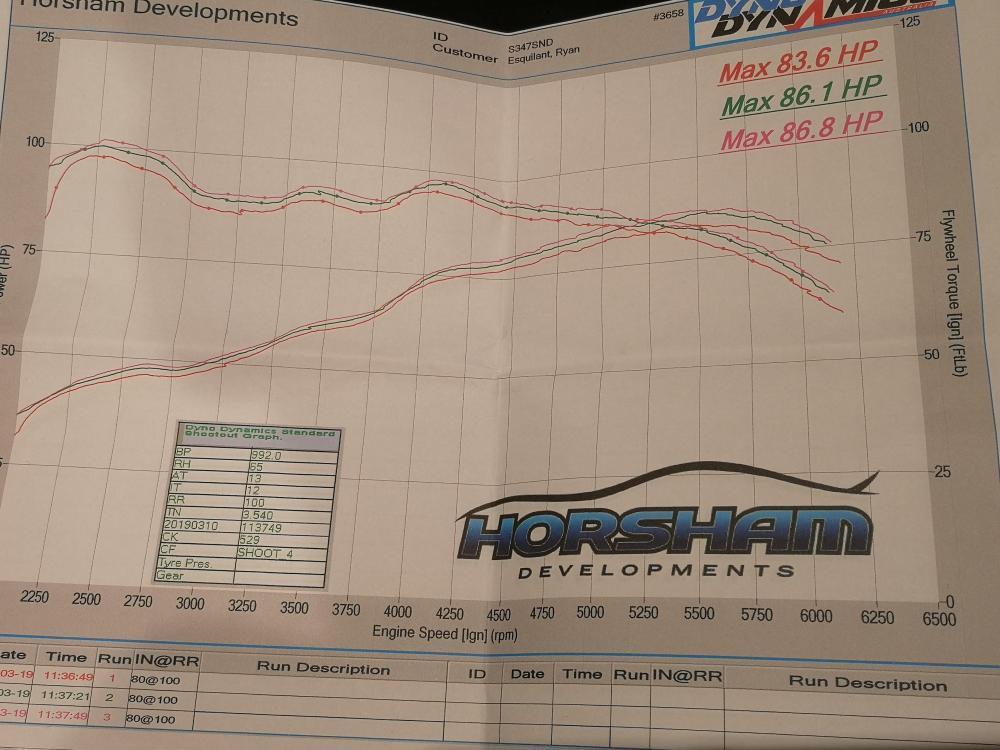

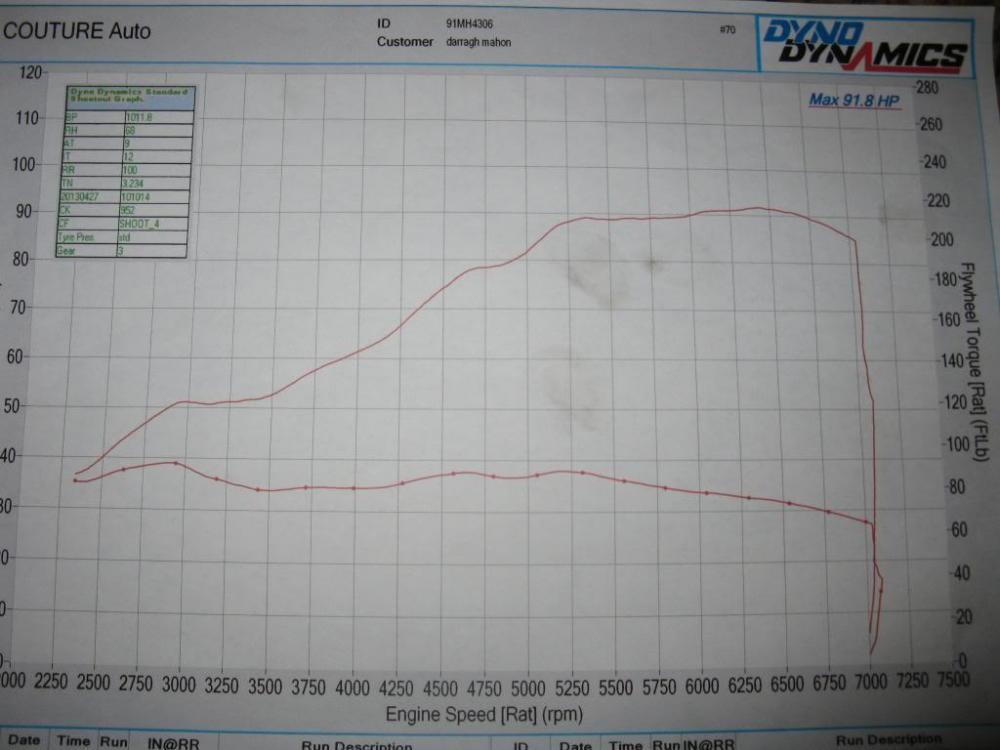

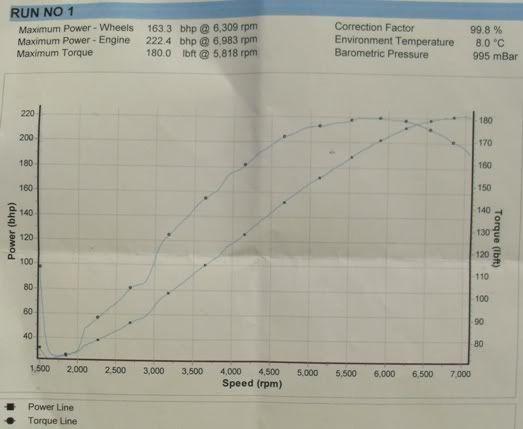

It'll will never be that my internet buddy never worry. It's good to bounce off ideas between us and others helps me settle on a general idea of the area to fouces on and try developing, this is something we do between the separate groups at work working on the same problems. Good things come from it. There's alot of capable people on here. The area I'm interested in is the power from 0rpm till around 6krpm to 6.5krpm. if I can produce as much torque as possible in this range with around 225hp then it's a very capable street setup rolling onto a motorway winner which is were the turbos like the bigger td04 take over. This graph in question does not fit the very tipical ct9/hyb graphs that are all over to be found this is why it here to be talked about. Here are some 4efe graphs very similar specs. You can see the 4.5k 4efe cam configuration drop out as well as possible fueling issues (Wavey lines). You can see 1 is better than the other. Look at how it hits the torque line harder but is present at the same point on the hp line. Now here is a ep80 gi using the turbo inlet, earlier ems system, the main difference is the inlet design as we all know now look it's seen in the graph (our understanding is the corrola inlet helps low rpm power and the turbo power inlet helps topend power).

-

The way I'm reading it is as follows. This graph in question (build)has big diameter items on it (exhaust and inlet). Aimed at peak power levels (to produce as much hp peak rpm as possible). This explains both the low rpm lack of power (engines low rpm gas flow rates) and high rpm good power, but not the torque curve at 6.5krpm being were it is. In order to get the good hp figures, afr can't be to far out tbh Normally you wouldn't hit top figures if there were a afr or ignition advance issues. There are always anomalies that can happen to produce a graph like this. (Cam timing out, afr and ignition timing not quite balanced at optimum Saying this the graph looks nothing like a ct9 sized turbo. The spool up power characteristics are missing, as well as the 4efte cam characteristics, droping torque off at 5.5krpm. with the small turbo hitting this drop off curve hard (high exhaust back pressure). The peak power figured and hp to torque difference of the engine do match a ct9 hyb and 4efte. Making this graph very interesting. Could incorrdct cam timing produce this. If so could changing engine items as well as afr/ignition advance help produce more. Also I've been looking at the blitz access plug and play ems. There's some great ct9 figures using this ems. I'm trying find how these are setup/do they share the same maps. The other points of interest for me: injector size on the ems as well as set fuel pressure.

-

Yeh its a funny 1. Possibly a false ct9hyb/4efte graph. It was more the topend power I was foucesing on. Like you say we could improve big time the lowwer rpm band using a ct9+ But 222hp @1bar is close to peak hp from this turbo at this pressure. from what I can find. I've found the highest so far is 227hp daztec ems. I'm looking for the graph now. peak torque at 6.5krpm is lowwer.

-

Just out of interest what figures would you be happy with on this setup. I'm finding good figures on the plug and play blitz Access ems. When I search them. Also the hks fcon

-

Its a tuff 1 going off the setup, this looks very similar to the 5e graphs I've seen but these normally produce more torque at these hp levels. I'd say it's a 4efte with the offset of hp to torque levels. It has to be cam setup. I've seen others, and tried to hold on that torque with turbo design and it's a balancing act with spool up. The 4efe cam setup make it even harder with a smaller turbo. I'm wondering if the cams have not been timed right upon installation at some point. I'm reading something about 5e builds bring set on 4e cam Mark. I've studied alot of Toyota e series graphs in the past 8 month. What's your thoughts?

-

I think you missed the point. @ 1bar there nice figures. With the setup listed. I'm just looking into the blitz access ECU are these programmable??

-

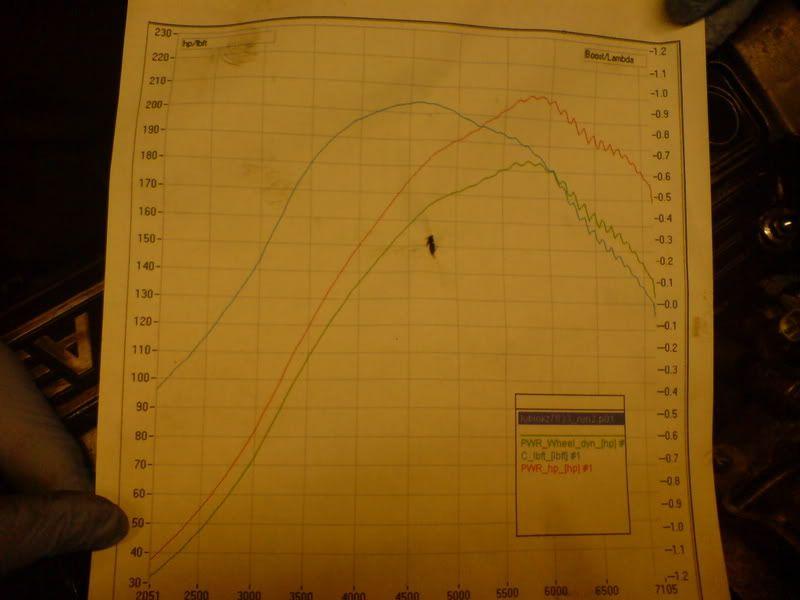

This is not the graph from the setup above in the video but a very impressive graph for a 4efte on a ct9 hyb. Mods are: - Tongs turbo G-spec hybrid HKS actuator - (1bar) Dave B mani and decat heat wrapped Kakimoto cat back Relocated air filter behind grill Baileys dump valve FMIC Walbro fuel pump 315cc Supra injectors TRD ignition leads SARD RRFPR at standard pressure 2.3bar Blitz Access ecu Civic Ali radiator Standard internals I'd expect the graph to look like this sharp torque drop out at 5.5krpm spec wasemanage blue maped by Chrissps manifoldautofix decatopen turbogt spec hybridblitz ssbcautobahn fmicbuddy club race spec 2 This torque drop out looks like this if you pick the wrong play ground to play in. The first graph would more than certainly match the tdo4 and might even beat it as the tdo4 will still see a torque drop at 5.5krpm on standard cams. Tdo4l hyb graph

-

Dutchies cam thread are his sparkplug thread. One of them.

-

Really enjoyed your build thread and some great things on here and happening. Any updates I know it's a long shot after all this time. Head gasket my starlet brother 99% the issue.

- 49 replies

.jpg.880fada5d5662c48430c6410f029d449.jpg.5e121687a8c4c74b9a2403bab3114581.jpg)