-

Posts

2434 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by funny onion

-

Yeah soaking it in a bucket would be the best way to do it but it may lose its shape and not fit back in the car too well...

-

Sam just did his in his GT. Think he mixed up some dylon in a spray bottle and sprayed it. looks pretty good

-

♛ Charlotte's EP70 Turbo- MOT Passed!

funny onion replied to funny onion's topic in EP70 & EP71 Progress Blogs

-

♛ Charlotte's EP70 Turbo- MOT Passed!

funny onion replied to funny onion's topic in EP70 & EP71 Progress Blogs

Thanks for the kind words everyone. I collected the engine parts from the machine shop on saturday, i'll put some photos up tonight. Both blocks were decked, one rebored to 74.5mm and both rehoned. one crank was perfect and just had a polish, the other was reground on the mains and big ends by 0.25mm and polished, and both heads were skimmed. I've just this minute put an order in with id-workz for oil pump, timing kit, bearings etc to get one built up for this, the other will get built up a little later. The axle is back on with new wheel bearings etc, the fuel tank is ready to go back on and i have a lift pump to fit to supply the swirl pot. The turbo kit arrived from Sacha too and it's gorgeous! I will put some pics up tonight -

-

Sounds like fueling issue. ie running lean. do you have a wideband gauge?

-

It's on the box on mine I'll have a look for you

-

I have 98 spec fogs in a 96 spec bumper and drilled the hole to fit but they just don't quite sit the same.

-

96 spec fogs won't fit. either put a wnated thread up or i think you can get them brand new still maybe? try id workz

-

No everything is fine no crunches, the shorter ratios give it more of a punch in the lower gears than a starlet box. only thing you have to modify is the shifter as reverse is next to first on this box. just need to notch some plastic from the shifter housing. gear cables, mounts etc are a straight swap

-

I have a G6 6 speed corolla gearbox in one of my GT's

-

♛ Charlotte's EP70 Turbo- MOT Passed!

funny onion replied to funny onion's topic in EP70 & EP71 Progress Blogs

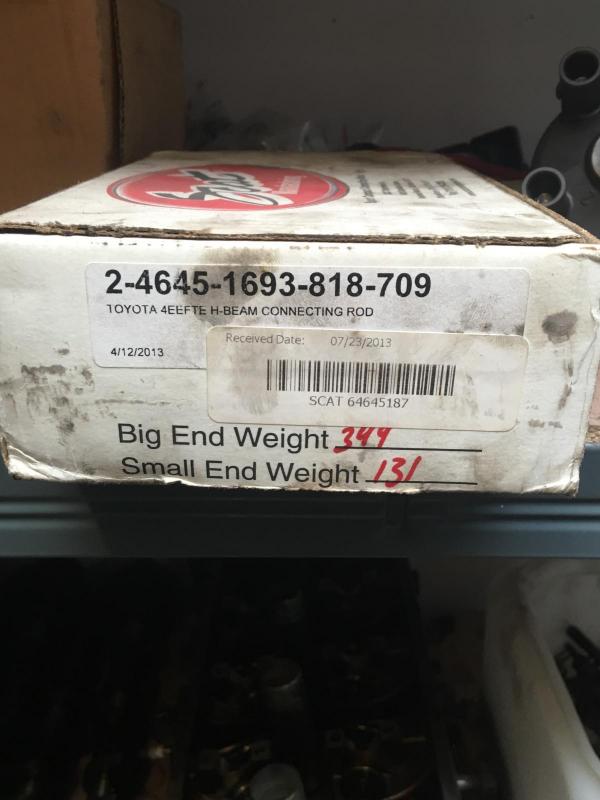

Update on the engine parts i took to the machine shop; Both heads and blocks are done, but the two cranks I took were both unserviceable big ends were too far gone. they were scored tbf but i had hopes they may regrind. So i took another 3 cranks up there last friday and two of those were serviceable. one needs a micropolish and the other is being reground and polished. Managed to get my final spare engine (out of the glanza) stripped this weekend. I was expecting the crank to be obliterated- it started knocking while i was using the glanza as a dailly. wasn't a terribly bad knock so i went for the pikey option of just changing the big end shells. However, i was totally on my own when doing this from start to finish. swapped the shells and built her back up, ran great but knocked when revved so i put it down to my error somewhere along the lines of changing the bearings. i like to have a go at anything and everything but i'm no mechanic. So got the sump off and pistons/rods out to find the crank and shells all looked really good tbh. there is a stamp on the crank by a company though so hopefully that just means it's previously been ground and knocked because i put standard size bearings in So all in all i should be picking up the completed components in the next week or so and starting to think about putting it all together. Need to notch the block for the scat rods etc. I'll get pics of engine parts and the knackered cranks for reference. -

Both my GT's are like this. it's the door switches on both of mine.

-

are you using the rad cap that came with the rad? try swapping it for a better one if so. I had a similar problem and mine turned out the be the shit rad cap, replaced it with a blitz one and it seems much better

-

not sure on the pins to be honest, not seen both to compare. i'd imagine you'll need to use wossner pins on wossner pistons, ross pins on ross pistons etc. tolerances are probably different. just make sure you get pins and circlips when you buy a new set of pistons if you havent already

-

As long as you replace them with the same diameter pistons they should be fine

-

I'd say if the earth from the battery had come off it will most likely be that. just see if it does it again. it could be the fuel pump i suppose, weak spark, or lack of fuel for some reason. but like i say most likely the the earth from the battery.

-

That's probably it. cleanup the earth and the surface on the chassis/gearbox wherever you're going to earth it too and should be ok.

-

♛ Charlotte's EP70 Turbo- MOT Passed!

funny onion replied to funny onion's topic in EP70 & EP71 Progress Blogs

The welders at my work are welding the turbo stub axles onto the EP70 beam. I wanted to bolt them on (nuts and bolts i would've gone for i think) but made a bit of a mess trying to grind the ep70 stubs off. plus if you bolt the turbo stubs onto the ep70 axle it would space it out by 10mm at either side... Once they've welded it up i'll get some pics. They're really good and i trust them to make a great job of it, like i say they've spent ages dressing the surfaces so it's all nice and flat etc. will be done in the next week or so hopefully! -

10w-40 semi.

-

amethyst purple glanzif! Volk split rims :) new brakes

funny onion replied to Rich-k's topic in EP91 Progress Blogs

Gutted for you rich. Someone keyed my advance while at was at work last year. I work on a military base too so it wasn't as if it was parked in a bad area. I'm sure you'll sort it, still gutting though. -

♛ Charlotte's EP70 Turbo- MOT Passed!

funny onion replied to funny onion's topic in EP70 & EP71 Progress Blogs

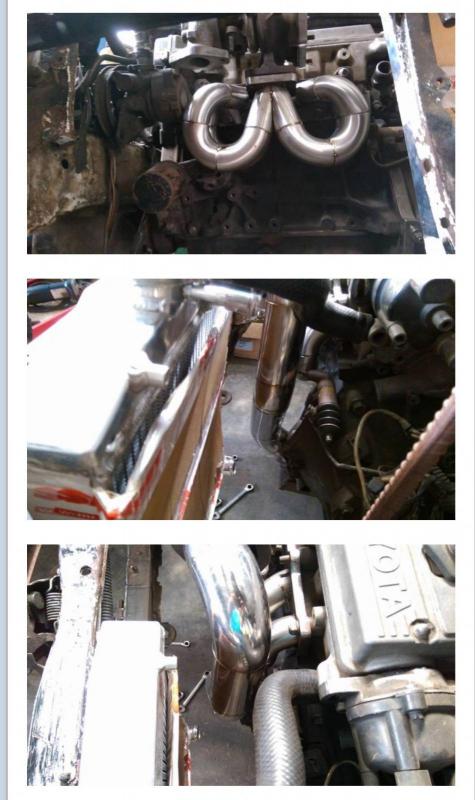

Another wee update... I dropped off 2 blocks, heads and cranks at park engineering in Malton. They machined the engine I built for the advance and 25,000+ miles it's still going strong so hopefully they will do a good job this time too! Everything is getting machined up, but the best block crank and head will be going in this. I'll build the other up as a spare engine. Hoping to get it all back in the next couple of weeks and then I can throw it all together. Just need to order an oil pump to suit whichever block is going in this and then I'm away hopefully. Pretty sure both block have the seal on the pump but I'll wait until they come back to save ordering the wrong type. Axle is coming along at work. Just needs welding now. The guys have spent a good while dressing it ready so it will all be nice and flat. The standard car loom is all in place. A lot of soldering to move the fuse box inside the car but it's done! Engine loom will begin once the engine is in. Battery is in the boot now and the power ran to the front of the car and kill switch in just needs mounting up. I mounted the bumper and headlight surround back on the front to get a look at the space I have to play with for the inter cooler. Reasonable amount of room in there really. Also got some sneaky pics from Sacha at wepr of the custom top mount ct9 manifold he's making up for me! It's all coming together nicely... Anyways... Pics! -

Trip to machine shop today!

-

Yeah I'll let you know. they have 185 tyres so i'm hoping they don't scrub too bad on coilovers