-

Posts

4744 -

Joined

-

Last visited

Content Type

Profiles

Forums

Wiki

Media Demo

Events

Everything posted by RobSR

-

4e-fe engine bay wiring diagram plus ignition help

RobSR replied to Mattlmr's topic in N/A E-Series Engine Discussions

So you’ll be running a 4efte ecu? If so it won’t work, as you need the ‘G1’ cam signal that isn’t on the 4efe dizzy. -

Yes you need to use a dyno, but if you’re not analysing the compressor map, how do you know you’re not driving the turbo into surge or going past the choke line before you physically hear surge or see the engine isn’t picking up more power with extra boost on the dyno? You can’t just use ‘feel’ if you’re doing things properly. If you reduce overlap to help drive the turbo, yes you will gain bottom end and response like you say, but then you’ll lose the top end. You can do one or the other with the cam, not both. A cam designed for a n/a engine is completely different to a properly spec’d turbo cam. Post up your graph and we can see the torque curve and compare.

-

4e-fe engine bay wiring diagram plus ignition help

RobSR replied to Mattlmr's topic in N/A E-Series Engine Discussions

Both are crank trigger, it’s a 2 wire reluctor sensor so has a + and -. The starlet doesn’t have a crank sensor on the crank. It takes it from the dizzy, as we know 2 crank rotations for one rotation on the head, so if you take the dizzy pulse and half it you have theoretical crank angle. -

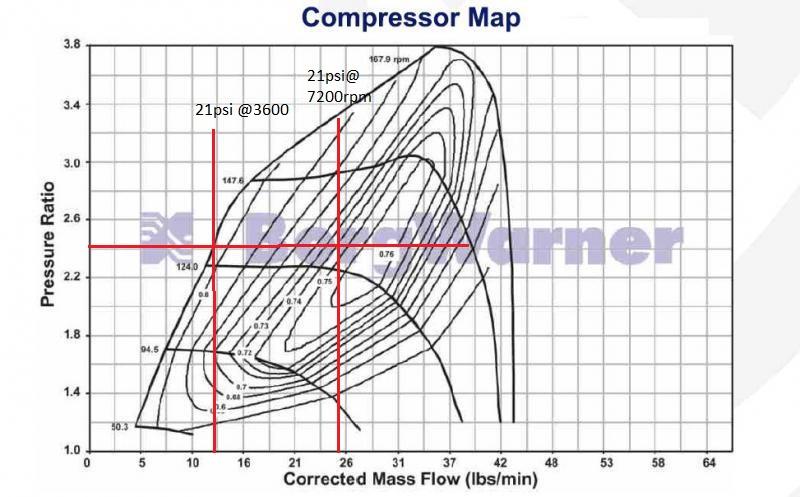

The stock head and cam won’t allow good high rpm torque. Look at any stock cam graph and the torque is all downhill from 5k, it starts to fall off a cliff. With a well thought out head, you will be able to get it to hold onto the torque until around 7k, where then it’ll start to drop off slowly. That was still on stock valve too. Why are you wanting to only rev to 5500? You should be making power past this, so you’ll be limiting your powerband unnecessarily imo. Youll need the compressor map from your chosen compressor wheel to calculate what boost you can attempt to target at x rpm to ensure you don’t go past the surge line. For example, I know I can’t target more than 1.4 bar on our EFR kit at 3600rpm or I’ll be past the surge line. It works the other end too so you know if you may be overspending the turbo, or chocking it.

-

4e-fe engine bay wiring diagram plus ignition help

RobSR replied to Mattlmr's topic in N/A E-Series Engine Discussions

They all go to the ecu, 1. NE - ecu, 2. NE- also ecu -

4e-fe engine bay wiring diagram plus ignition help

RobSR replied to Mattlmr's topic in N/A E-Series Engine Discussions

The 4 wires running to the ecu from the distributor on the n/a are: NE NE- : these are crank trigger input. IGT: this is the spark event request sent out by the ecu to fire the coil. IGF: this is a feedback signal sent by the coil back to the ecu when a successful spark event has took place. Essentially if the ecu doesn’t receive a IGF signal back from the coil for ‘x’ amount of times it’ll log a fault code. 4EFTE run seperate coil, igniter and distributor. The distributor also has 4 wires, however they are NE, G1, G2 and G-. NE: Crank signal trigger input G1 and G2: 2 x cam signal input , each are 180deg apart to help with quick starting also. G-: Signal Ground hope that helps, -

How many people are defo going? Silverstone is pretty close so could join!

-

As it’s a PnP I presume ME made it to run with the stock wiring? I don’t map ME so they’ll need to confirm. If so, remove your stock solenoid and replace with the 3 port. Doesnt matter what way round you wire it. One side is 12v from EFI relay other side runs to ECU If wiring has been removed, go with what I said in my original reply at the top as that’s how it’s done stock.

-

272 is just about ok on a 2860 imo, I personally would never go 3071 on a starlet, but if you do and it’s being used on the road,you want to go shorter duration, 25* region or even less unless it’s a drag engine.

-

It really depends what you want to do with the engine powerband. The nice thing about a TD04 is, it’s relatively responsive, however torque nosedives after ~5200rpm, so you could go for a slightly longer duration cam to help past this point. You will however lose a little bottom end however. If you want to improve the mid range, go for a shorter duration cam with less overlap to help drive the turbo. On a ported head, with stock valves I’ve made power to 8500rpm on a mild lift 272 that you can still use with the stock shim on top of bucket arrangement. It’s quite a nice all rounder. I personally wouldn’t bother with a longer duration unless it’s a drag car and you’re trying to change you EMAP v MAP ratio drastically.

-

Replied to your other topic but they are clip

-

Wich one type fit on ep82 mk3

RobSR replied to Alexandros Stavrou's topic in EP80/EP82 Progress Blogs

As long as it’s still on the same cap the car cams with they are clip type. -

Coming along nicely mate

-

You can buy the ecu connectors from TE if that’s all you need. They are only a few ££ each.

-

Last 2x kits in stock sold! We will start our next production batch shortly so please feel free to get in touch if you’d like to secure one!

-

Yes I’ve done 300 on them without issue

-

Josh's forged 5E Massive spec forged build! 370BHP!!

RobSR replied to wakeabby14's topic in EP91 Glanza Progress Blogs

Coming along nicely! -

You’ll do 280 on a TD04 on a 5e, so you can have the power you want and the spool of a TD04

-

You’d hear it if it was; it could be that if your original turbo had an internal Wastegate that had been welded/held closed for use with the external one this could have come undone.

-

Are you running an external Wastegate?

-

Checked all your intercooler pipes are still together and no noses have split?

-

Yup that’s a good way of doing it, I was assuming you’d be doing something along the lines of that

-

Sounds good. What is your plan for controlling the supercharger? Fixed boost based on pulley size, or will you be adding a bypass to regulate boost to your desired target?

-

When is the target to have it running and tuned?